Plate manufacturing device and method capable of achieving automatic loading and unloading and extrusion forming

A technology of extrusion molding and automatic loading and unloading, which is applied to lamination devices, chemical instruments and methods, lamination, etc., can solve the problems of equipment utilization efficiency to be improved, waste of labor costs, and long time-consuming, etc., to achieve the benefit of industrial development , Reduce industrial investment and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The technical solutions of the present invention will be further described in detail below with reference to the drawings.

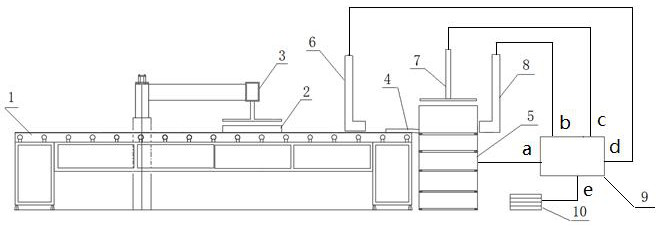

[0008] The present invention will be further described below. See figure 1 , A panel device for automatic loading and unloading, including a transfer system 1, a panel assembly 2, an automatic load-bearing plate system 3, a plate component limit frame 4, a molding box 5, a push rod system 6, an extrusion molding Device 7, the box push rod system 8, the control device 9, and the electric system 10; the transfer system 1 is an electric feed system with a switch, which can transmit a plate material within 1 meter of the width; plate assembly 2 is a multilayer sheet. The components are different, and each layer is different, and it is a raw material plate of extruded molded sheets; the automatic load removal board system 3 is a loading and unloading of the handling sheet to capture the handling plate with a plurality of suction plates in combination with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com