Arc-shaped reinforced pressure-resistant bulkhead structure capable of resisting underwater explosion impact bending

A technology of underwater explosion and pressure-resistant chamber, which is applied in the direction of hull bulkhead, hull, ship construction, etc., can solve the problems of large plastic deformation of the inner plate of the liquid tank, punching plug perforation, petal tearing, etc., to improve the protection ability, Effect of reducing deformation and enhancing watertightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

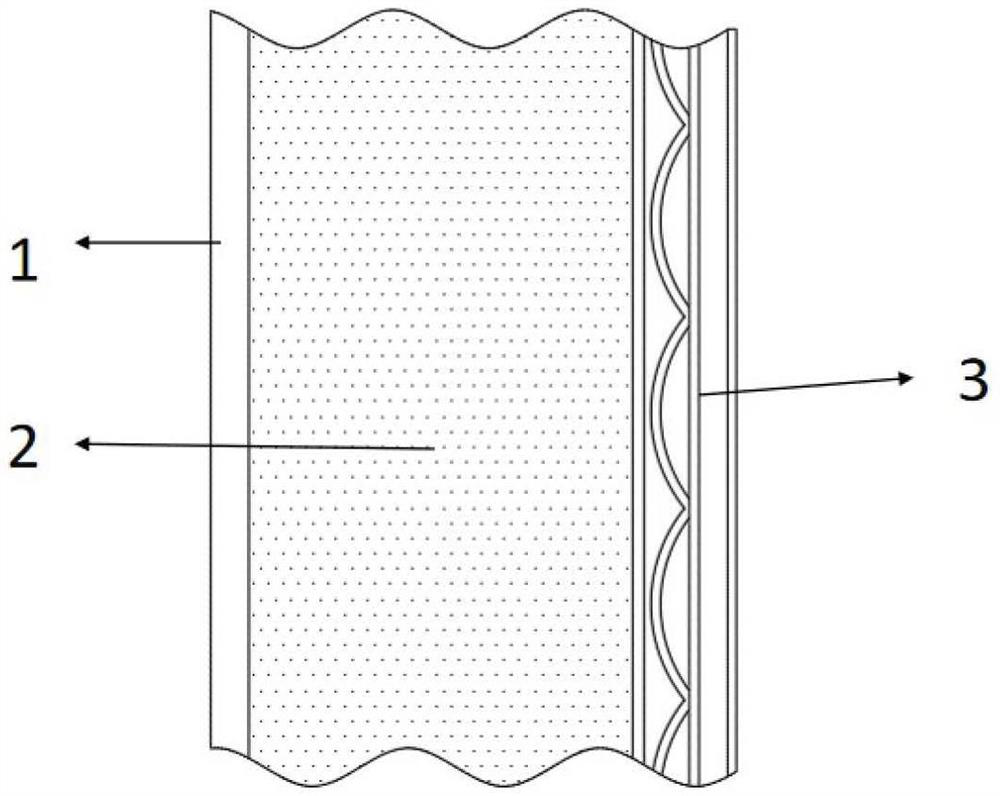

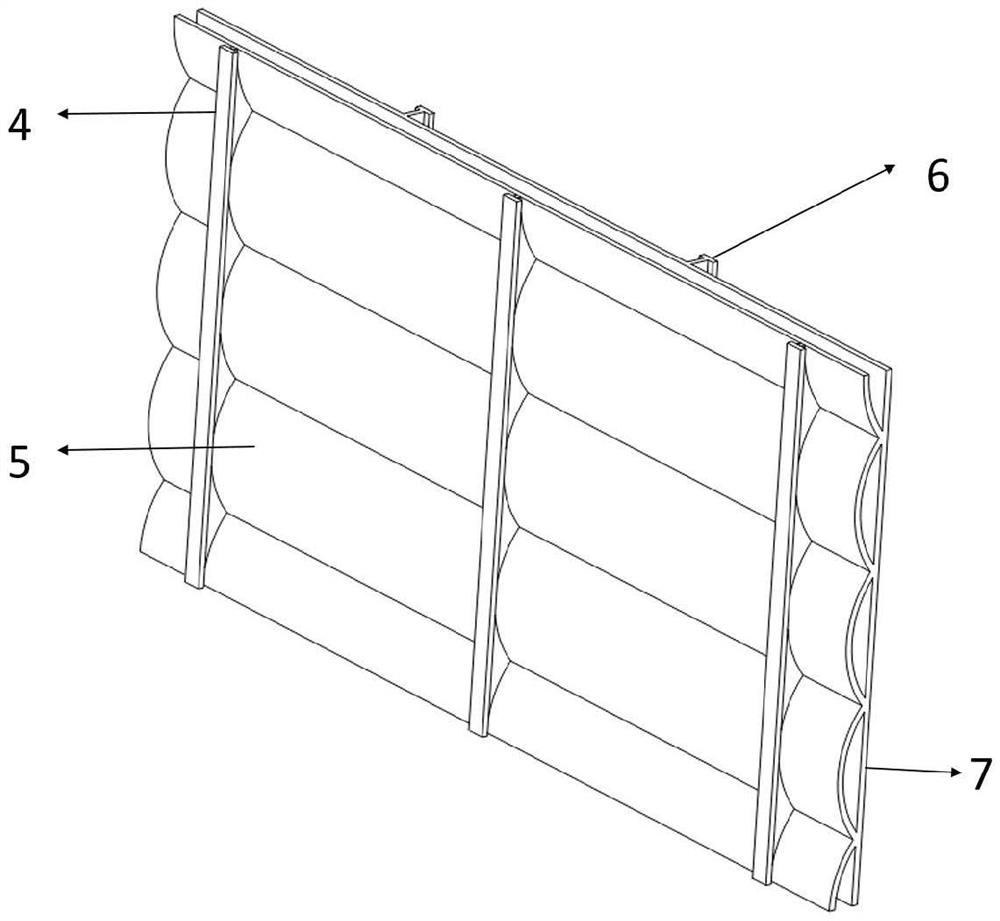

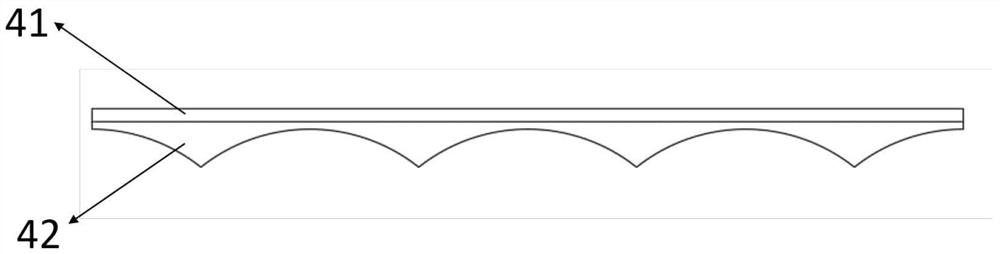

[0023] Specific implementation mode one: combine Figure 1~3 Describe this embodiment, an arc-shaped reinforced pressure bulkhead structure resistant to underwater explosion impact bending, which includes an inner panel 7, a protective structure fixed on the side of the inner panel 7 close to the protective liquid tank, and a protective structure on the side of the protective structure. A number of first ribs 4 and a number of second ribs 6 located on the side of the inner panel 7, wherein the protective structure includes a number of arc-shaped support plates 5 arranged horizontally and connected side by side from top to bottom, the first ribs 4 and There is no gap between the protective structures and between the second rib 6 and the inner panel 7 .

[0024] The arc-shaped reinforced pressure bulkhead structure in this application is preferably applied to the structure of the tank inner plate 3 . The protective structure and the outer panel 1 of the tank jointly form the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com