Ceramic piezoelectric type same-platform linear front-back reciprocating conveying vibration machine body

A ceramic piezoelectric and vibrating machine technology, which is applied in conveyors, vibrating conveyors, transportation and packaging, etc., can solve the problems of manpower consumption and low efficiency, and achieve the effects of cost saving, fast response performance and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

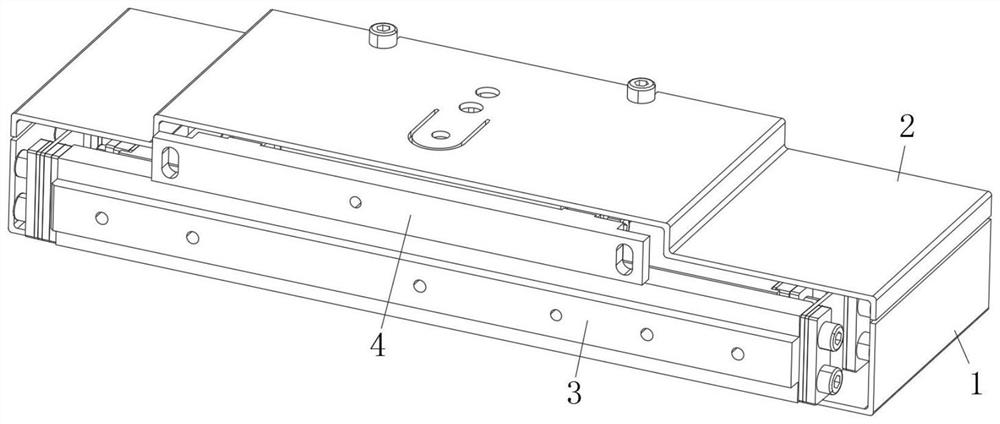

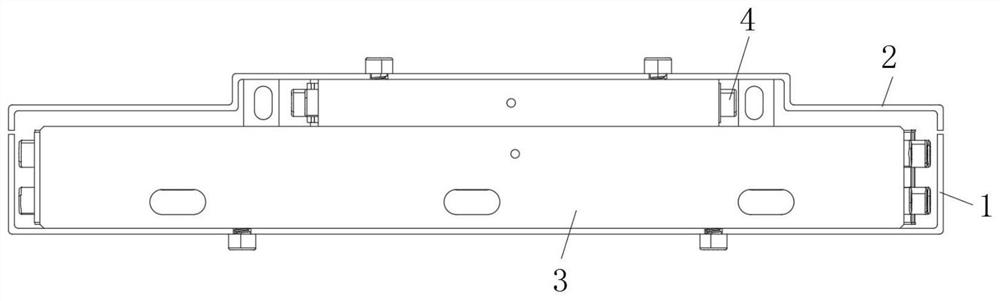

[0027] Refer Figure 1-6 A ceramic piezoelectric equipped with a platform back and forth to retrore the vibrating machine body, including the vibrating machine cartridge body 1, the top end of the vibrating machine cartridge body 1 is fixed by the screw 2, the inner side wall of the vibrator cartridge body 1 is mounted The reciprocating conveying assembly 3, the upper side of the reciprocating conveying assembly 3 is mounted, and the rotary vibrating machine body 4 includes a main vibrating seat 41, a front side of the main vibrating seat 41, a front vane 42, a main vibrating seat 41 rear end? After both sides are installed, there is a rear vaporizing seat 43, and the rear vapillary seat 43 is provided with a drive seat 44 between the front vapilizable seats 42, the drive seat 44 and the main vibration seat 41 side wall, front vaporizing seat 42 side wall and After the side wall of the rear, the ceramic piezoelectric sheet 45 is fixedly mounted, and the main vibration seat 41 is fi...

Embodiment 2

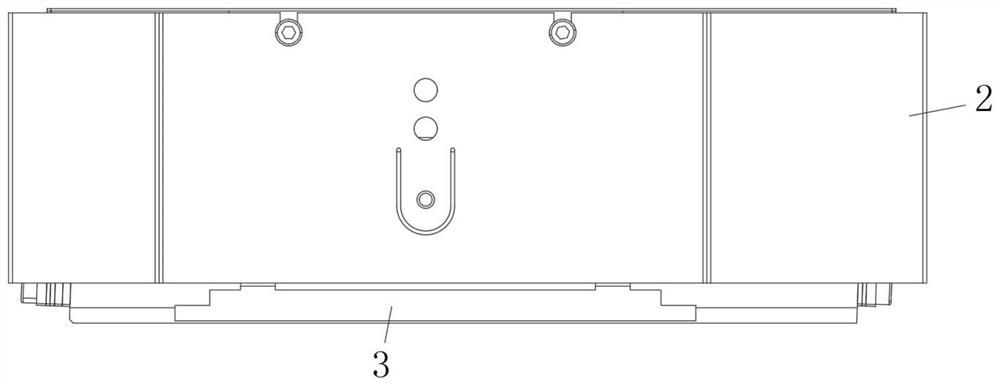

[0029] Such as Figure 1-4 As shown, the present embodiment is substantially identical to the first embodiment, preferably, the cover 2 employs precision cast aluminum to form a formation process in which CNC is integrated with a five-axis CNC.

[0030] In this embodiment, the cover 2 is machined by the CNC integral processing, which will reduce the cost of the processing material by 10%, integrated top cover, and the angle will be more accurate and other connectors will be better, improved. The top cover processing, the structural strength is better, the processing accuracy is higher, and the assembly can be assembled more accurate in the actual assembly process, the assembly time is shorter, and the cost of saving labor costs is mainly the new structure of the design. In the actual application after assembly, the vibration frequency of the vibrator is higher, the conveying material is higher, the speed is faster, and is not from external force.

Embodiment 3

[0032] Such as Figure 5 and 6 As shown, the present embodiment is substantially identical to the first embodiment, preferably, the three ceramic piezoelectric sheets 45 average the three ceramic piezoelectric sheets on the main vibrating seat 41 are used as a common vibration source.

[0033] In the present embodiment, the average number of vibration sources is equal to 120 degrees angle, so that the rotation vibration is more efficient, more smooth, and the clockwise, counterclockwise transport is achieved by the change in the angle direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com