Building drainage structure

A technology for building drainage and No. 1, which is applied to buildings, water supply devices, pipe components, etc., can solve the problems of easily damaged connectors, affecting the indoor living environment, and water seals that cannot be used normally, so as to improve service life and improve indoor living. Environment, effect of quick installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

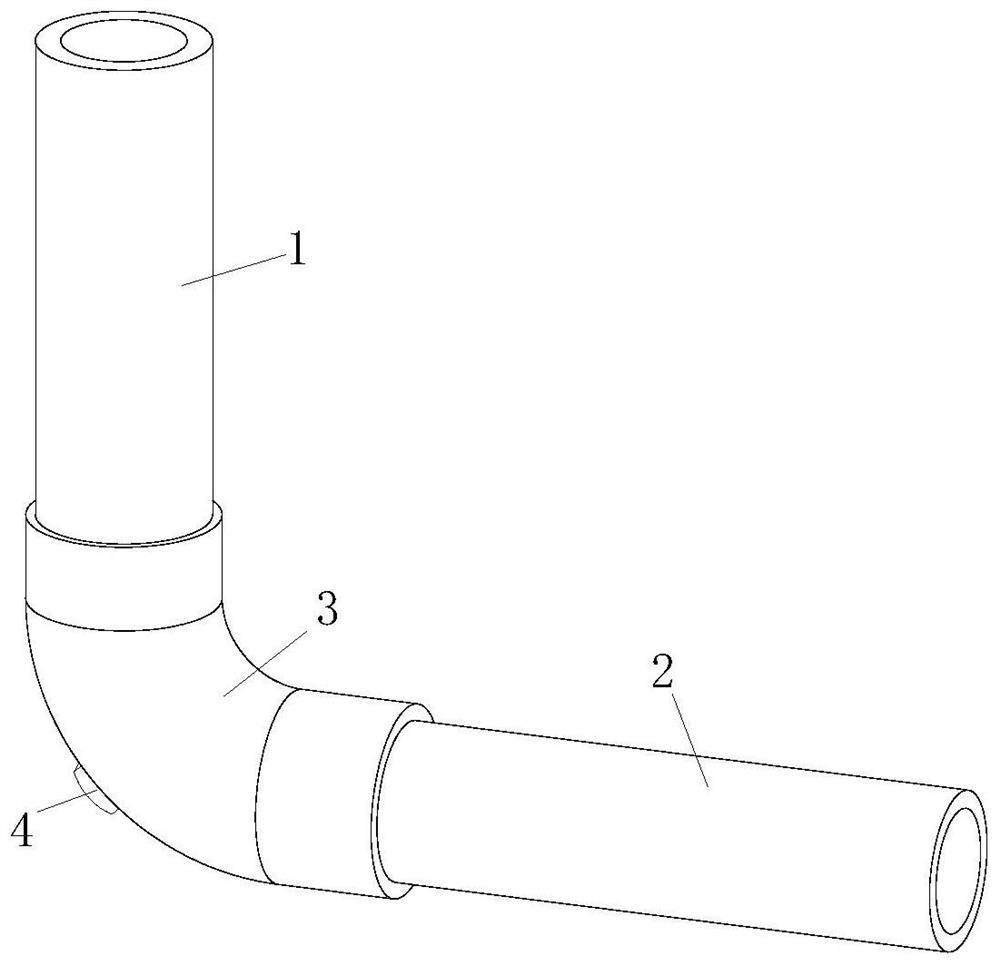

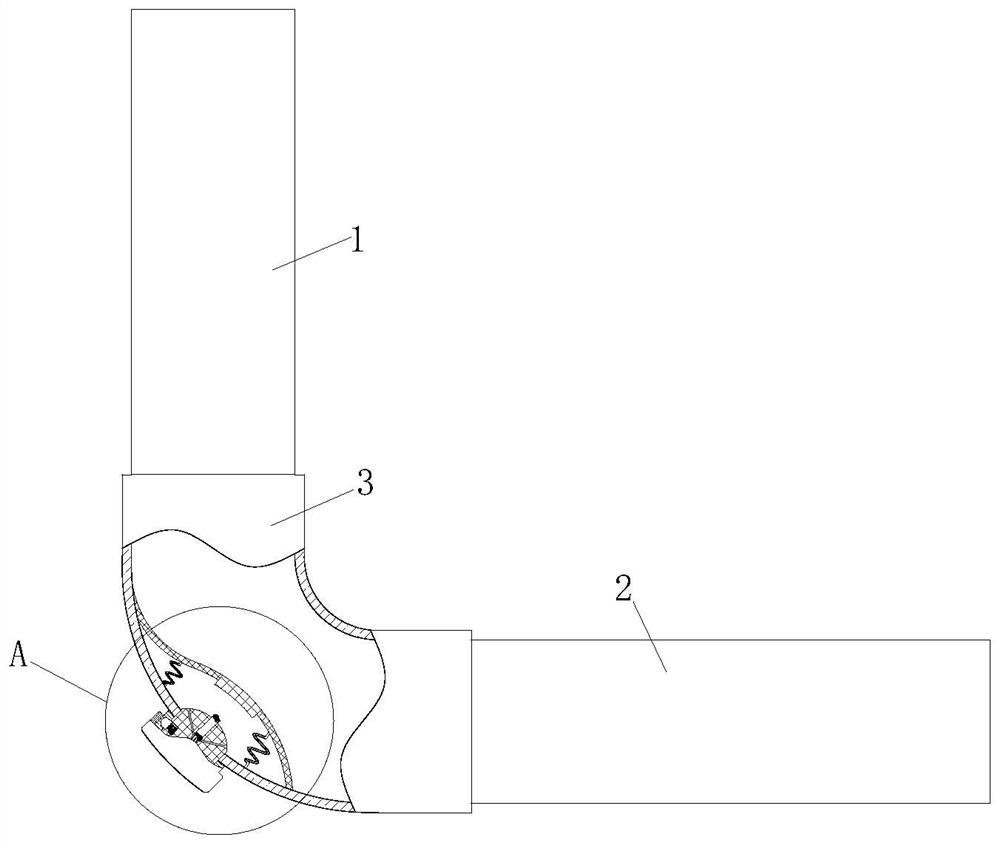

[0037]a building drainage structure, Figure 1-Figure 3 As shown, it includes a vertical pipe 1, a horizontal pipe 2 and a pipe joint 3; the vertical pipe 1 and the horizontal pipe 2 are connected through the pipe joint 3; it also includes:

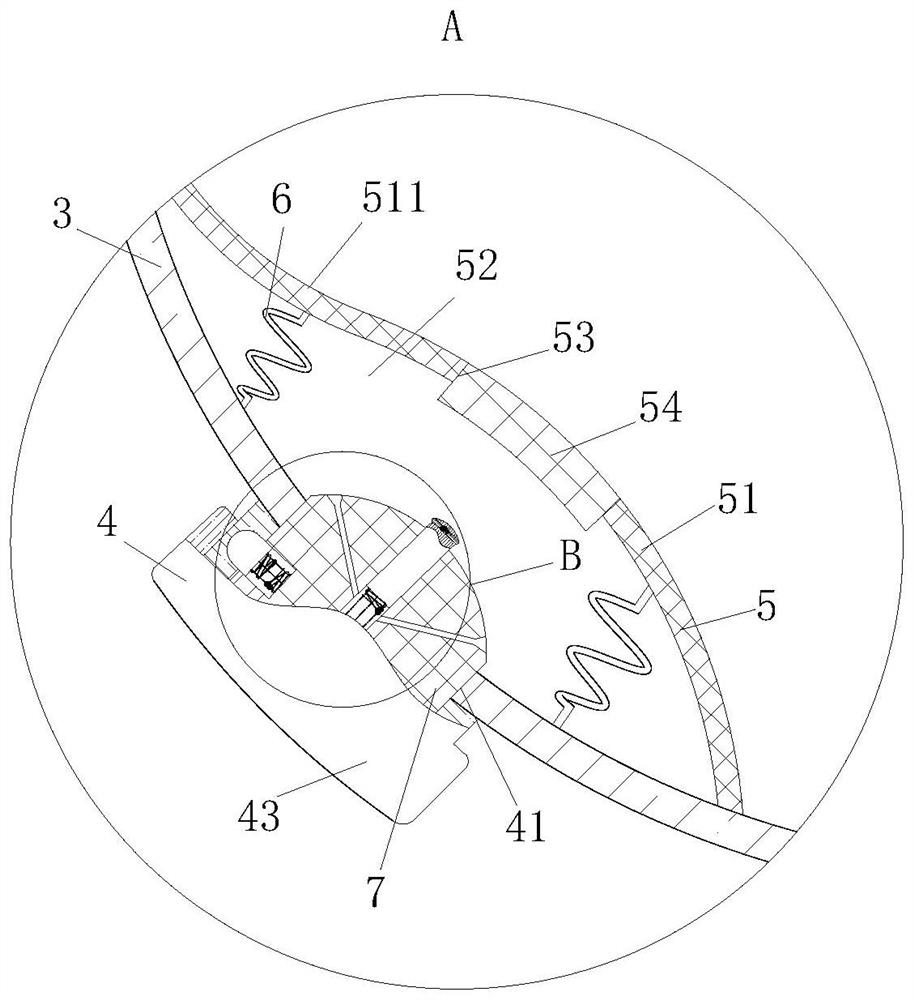

[0038] The anti-blocking module 4, the anti-blocking module 4 includes a through hole 41 provided on the pipe joint 3, a No. 1 pipe 42 installed on the outer wall of the pipe joint 3 and communicated with the through hole 41, and a No. 1 pipe 42 threaded. Closing cover 43;

[0039] The buffer module 5, the buffer module 5 includes a buffer shrapnel 51 arranged on the inner wall of the pipe joint 3 and located at the corner of the pipe joint 3; a No. 1 area 52 is formed between the buffer shrapnel 51 and the inner wall of the pipe joint 3, and the buffer shrapnel 51 A No. 1 hole 53 is provided, and an elastic sealing plug 54 is threaded on the No. 1 hole 53;

[0040] The through hole 41 is on the same plane as the No. 1 hole 53, and the ...

Embodiment 2

[0046] The difference from Embodiment 1 is that, as Figure 2-3 As shown, a group of pagoda-shaped springs 6 are arranged in the No. 1 area 52; one end with a large diameter in each of the pagoda-shaped springs 6 is connected to the inner wall of the buffer shrapnel 51, and the small-diameter end is connected to the end of the pipe joint 3. on the inner wall;

[0047] By arranging a group of pagoda-shaped springs 6, it is possible to further improve the buffering effect of the buffering shrapnel 51 on water and excrement, and to improve the restoring force of the buffering shrapnel 51, so as to prevent the buffering shrapnel 51 from being unable to buffer water and excrement. Restore; In addition, the big end of pagoda-shaped spring 6 diameters is connected on the inwall of cushioning shrapnel 51, when pagoda-shaped spring 6 was compressed, increased the contact area with buffering shrapnel 51, further ensured that buffering shrapnel 51 is opposite to water and Buffering effe...

Embodiment 3

[0051] The difference from the second embodiment is that, if Figure 2-Figure 4 as well as Figure 7 As shown, the No. 1 tube 42 is provided with an elastic column 7; one end of the elastic column 7 is located in the No. 1 area 52, and the other end is located in the No. 1 tube 42 and above the inner end surface of the blocking cover 43;

[0052] A No. 1 groove 421 is provided on the inner wall of the No. 1 pipe 42; a No. 2 slot 71 equal in diameter to the No. 1 slot 421 is provided on the elastic column 7, and an elastic clamping post is connected to the No. 2 slot 71 by a spring. 72. Through the mutual cooperation between the elastic clamping column 72 and the No. 1 slot 421, the locking of the position of the elastic column 7 is realized;

[0053] The elastic column 7 is provided with the No. 3 slot 73 communicating with the No. 2 slot 71, and the No. 3 slot 73 is provided with a push rod 74; one end of the push rod 74 is connected with the elastic clamp post 72, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com