Sectional type inclined groove blade characteristic parameter optimization method for ventilated brake disc

An optimization method, the technology of inclined grooves, applied in the direction of brake discs, brake components, brake types, etc., can solve the problems of backflow areas on the suction side, uneven channel heat dissipation, and less research on the optimization of the characteristic parameters of segmental inclined groove blades And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below with reference to the accompanying drawings and examples.

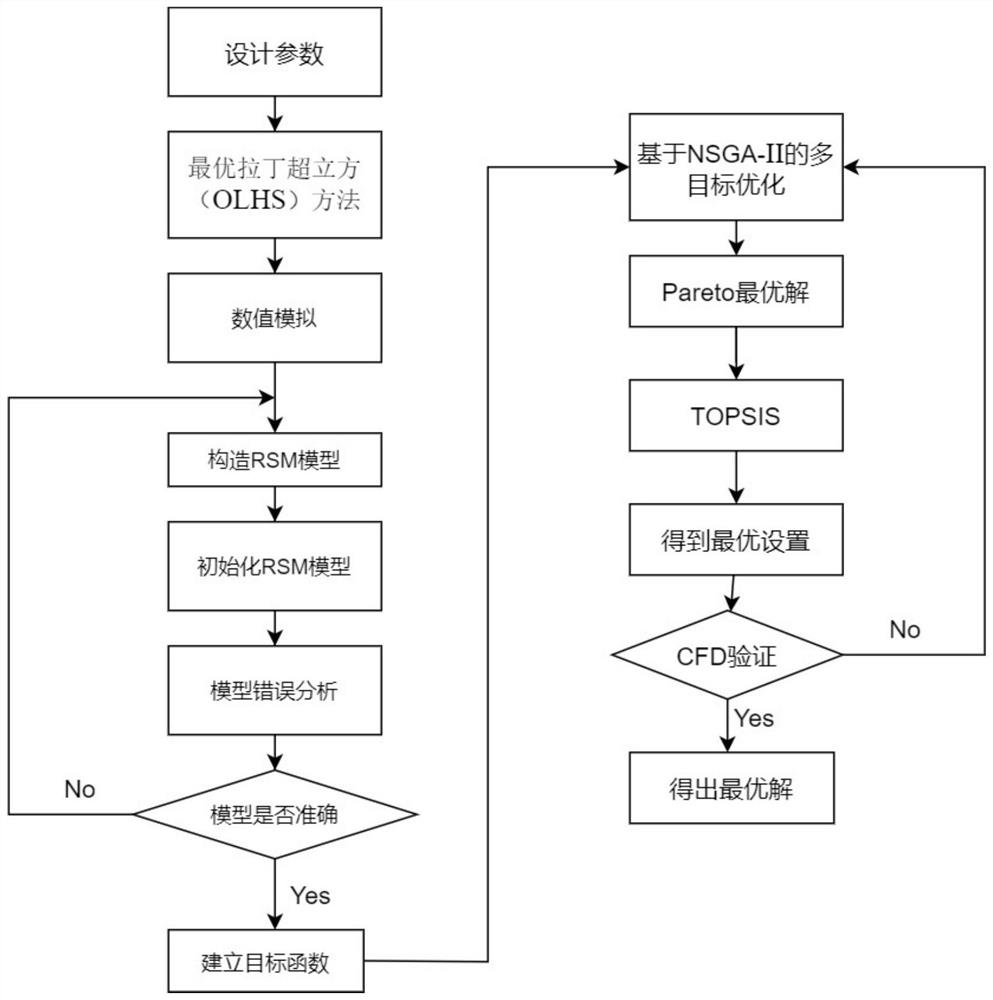

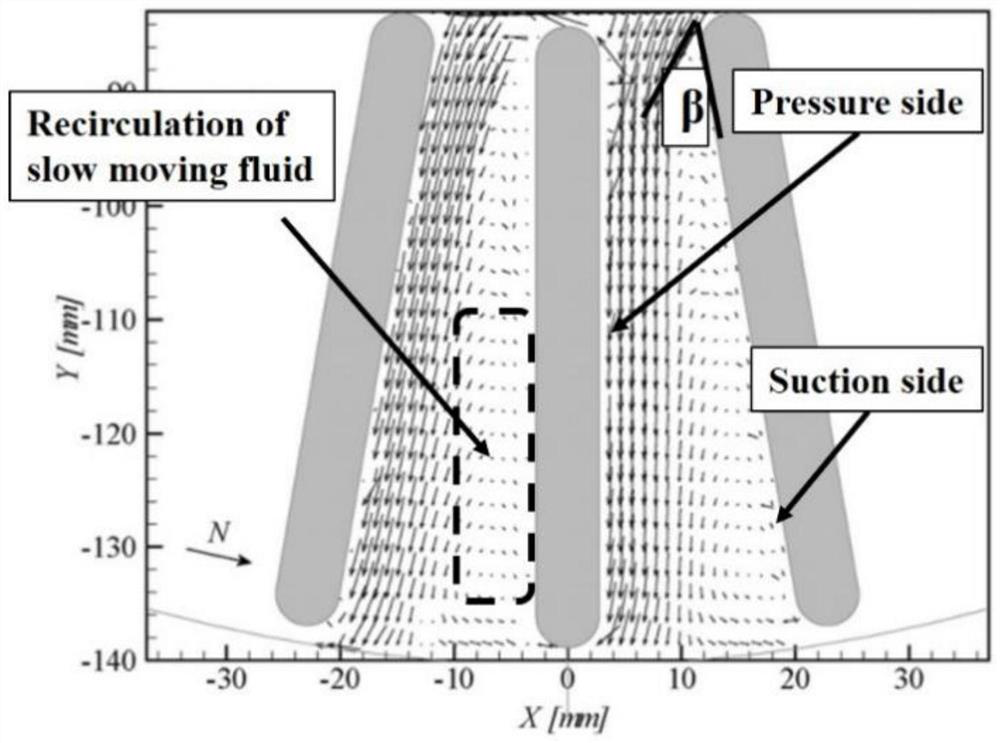

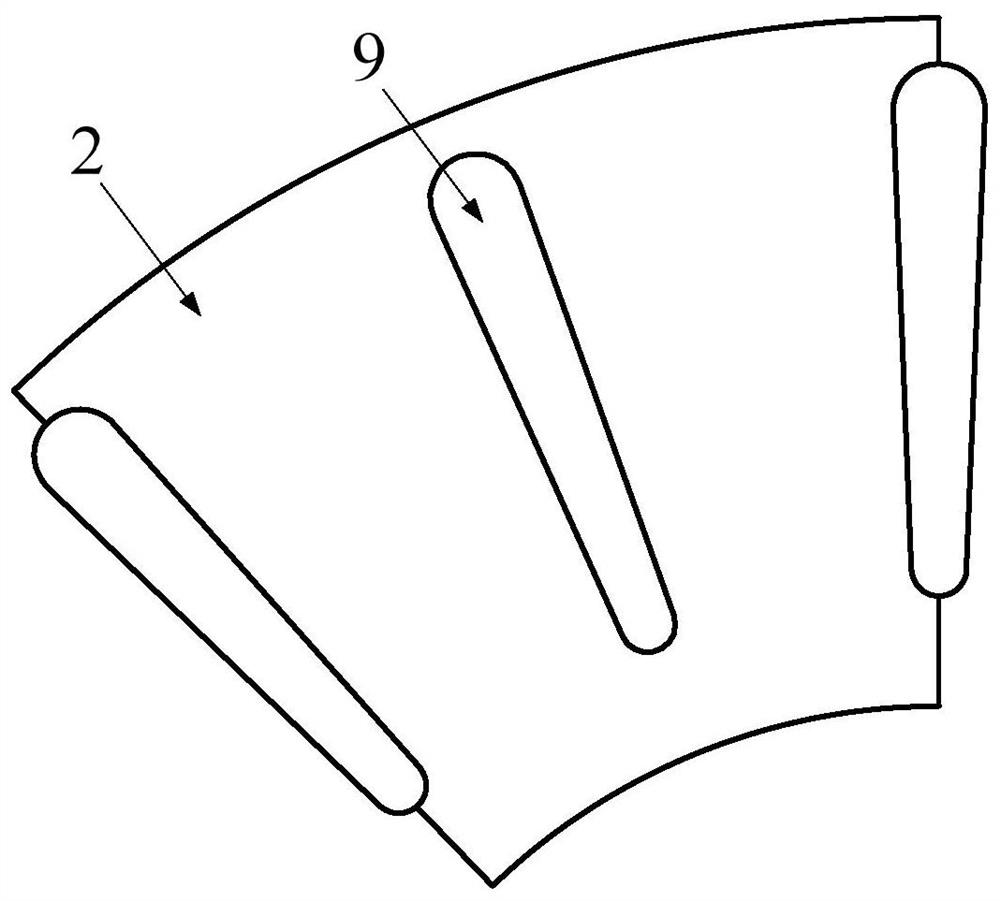

[0051] The embodiment of the present invention provides a method for optimizing the characteristic parameters of the segmented inclined groove blades of the ventilated brake disc. The structure of the straight blade 9 of the existing ventilated brake disc is as follows: figure 2 with image 3As shown in the structure, the structure of the ventilated brake disc in the embodiment of the present invention is as follows Image 6 As shown, the ventilated brake disc of the embodiment of the present invention has two outer friction surfaces 1, two opposite inner surfaces 2, and a plurality of heat dissipation blades connected between the two inner surfaces 2. A cooling passage 6 is formed between the cooling fins, one side of the cooling passage 6 is the pressure side 8 (Pressure side), and the other side is the suction side 7 (Suction side); multiple cooling f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com