Clip type sheet LED patch structure and patch method thereof

A LED patch and pull-clip technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problem of stress and temperature field distribution, difficult selective bonding, difficult control of bonding area and thermal influence, etc. problems, to achieve the effect of being suitable for mass production, strong heat dissipation performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

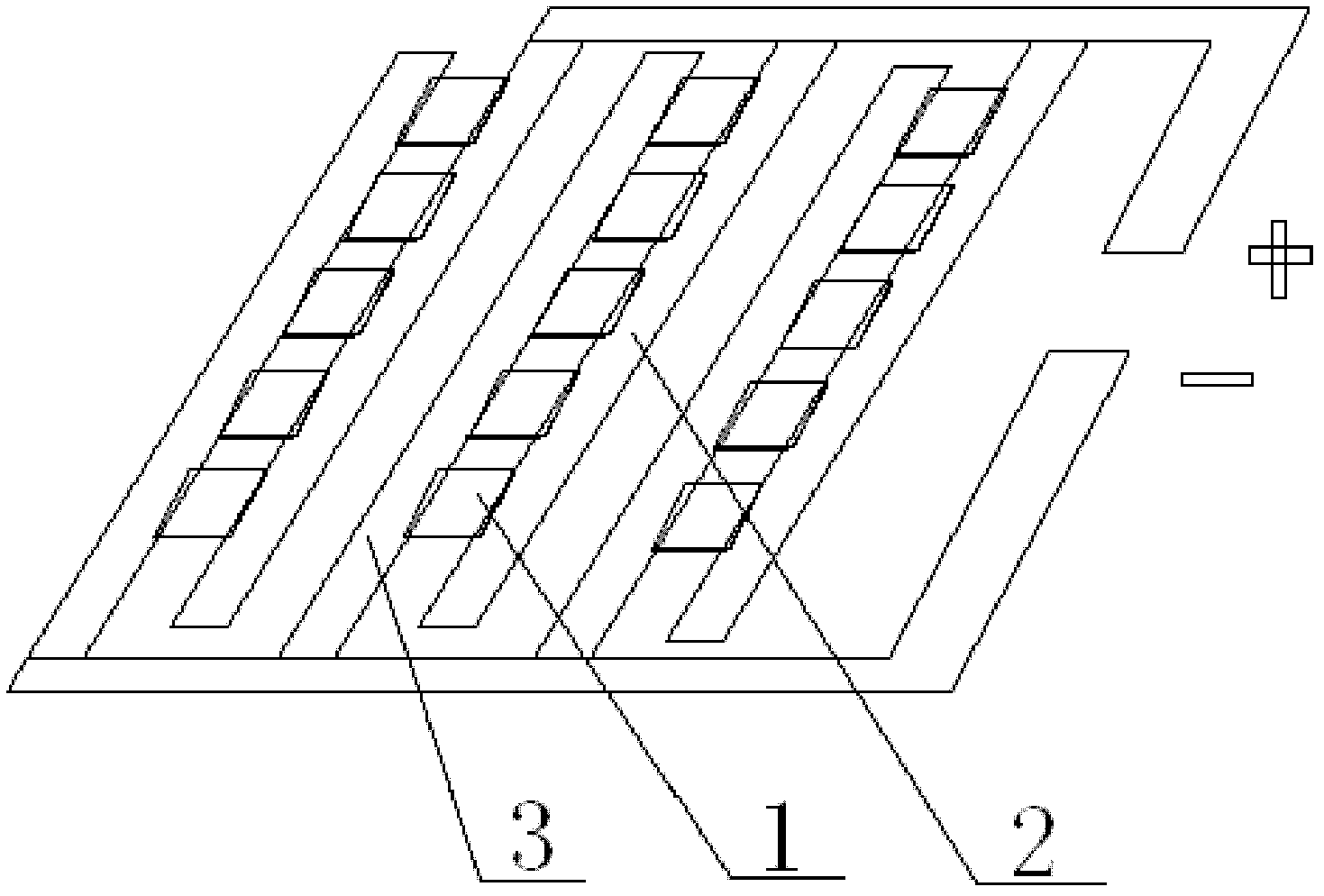

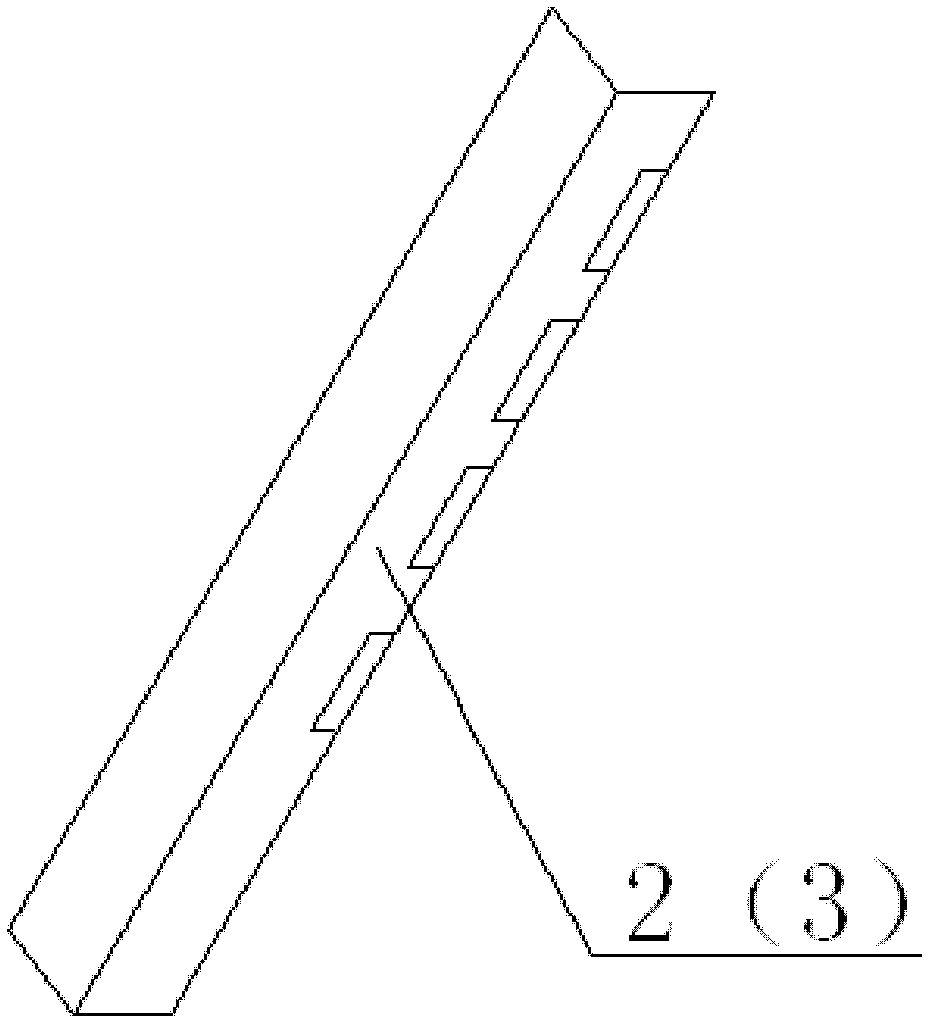

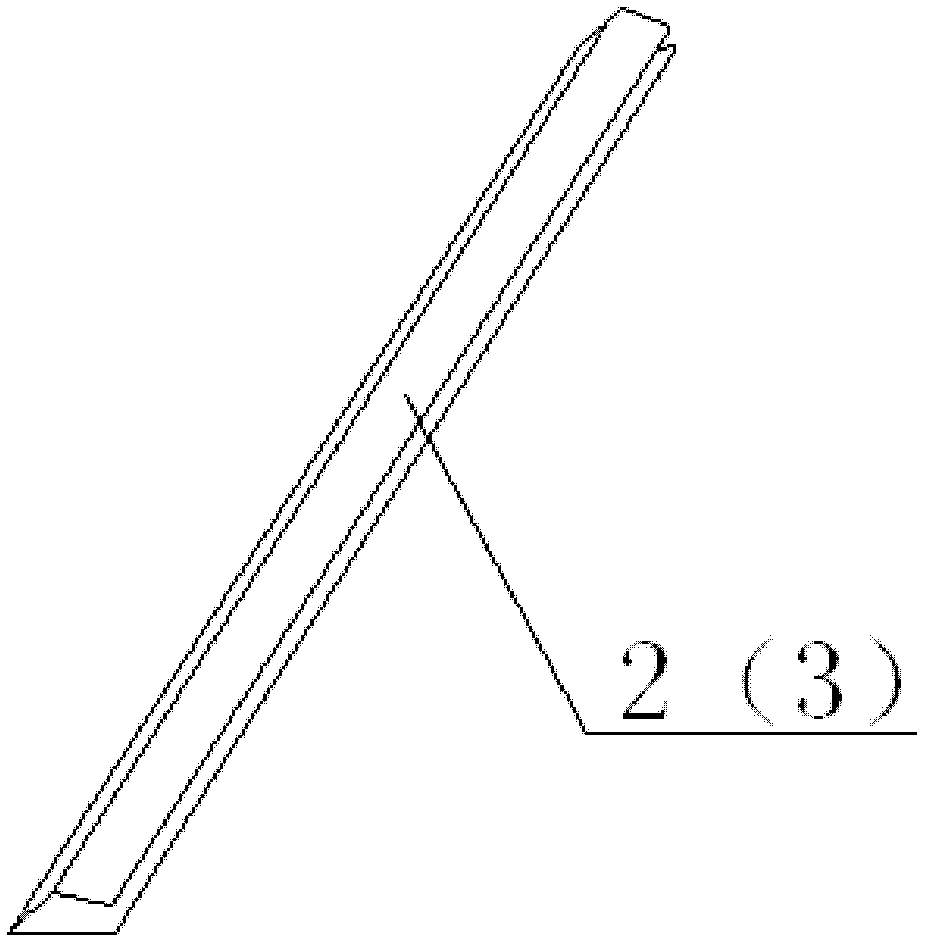

[0031] Such as figure 1 Shown is a pull-clamp type thin-chip LED patch structure, including LED lamp beads 1 and two pieces such as figure 2 , image 3 In the shown pull-clip metal, the two pieces of pull-clip metal are recorded as the positive pull-clip metal 2 and the negative pull-clip metal 3 respectively; The negative pull-clamp metal 3 is clamped to form a Figure 4 Single strip clip-on LED assembly shown.

[0032] As shown in the figure, a single pull-clip LED component constitutes the simplest structure of a pull-clip sheet LED patch structure.

[0033] Such as figure 2 , image 3 The area on the clip-type metal used to clamp the LED lamp bead 1 is marked as the LED bonding area. On the opposite sides of the clip-type metal, one side is a smooth surface, and the other side is LED bonding area. The area is a groove; the base material of the clip-type me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com