Emergency early warning method and system for fault of explosion-proof lamp of oil station

A technology for explosion-proof lights and faults, which is used in electrical transmission signal systems, alarms, instruments, etc., can solve the problem that the explosion-proof lights of gas stations cannot be warned in time, and achieve the effect of accurate judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

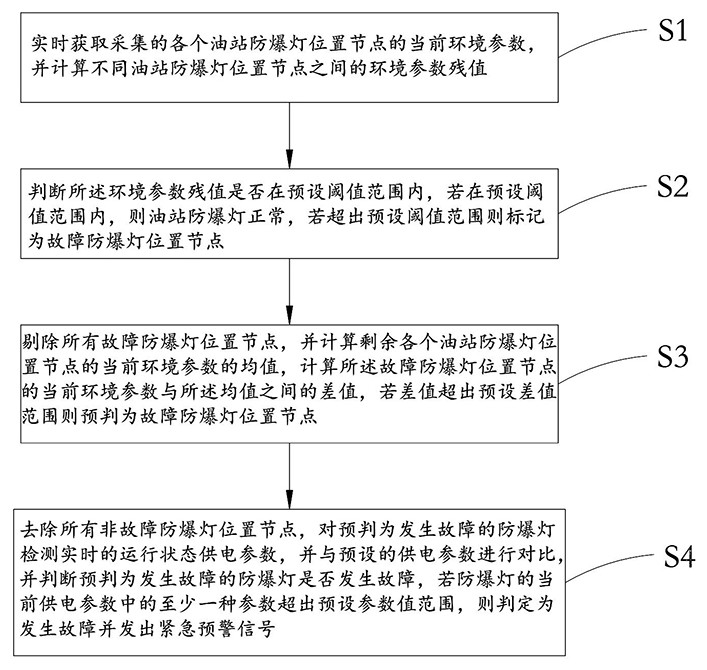

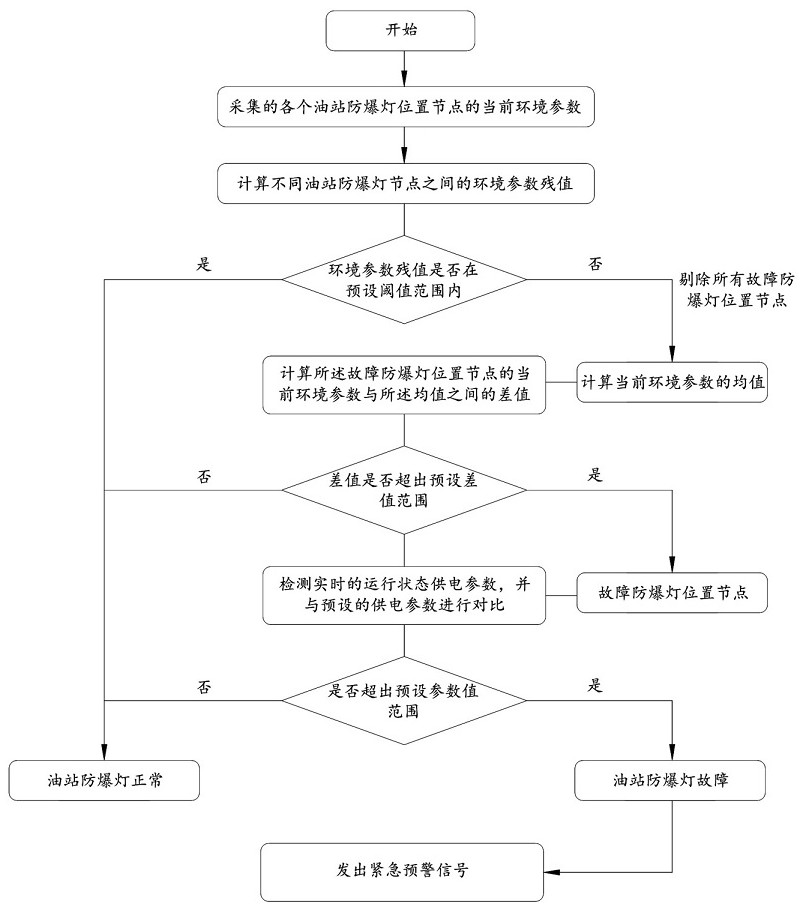

[0049] see figure 1 and figure 2 As shown, one embodiment of the present invention provides a method for emergency early warning of explosion-proof lamp faults in gas stations. The method includes a cross-detection mechanism for environmental parameters and power supply parameters to double verify the fault information of explosion-proof lamps. Specifically include the following steps:

[0050] S1. Obtain in real time the current environmental parameters of the collected explosion-proof lamp position nodes of each gas station, and calculate the residual value of the environmental parameters between the explosion-proof lamp position nodes of different gas stations;

[0051] S2. Determine whether the residual value of the environmental parameter is within the preset threshold range. If it is within the preset threshold range, the explosion-proof light of the gas station is normal. If it exceeds the preset threshold range, it is marked as a faulty explosion-proof light position...

Embodiment 2

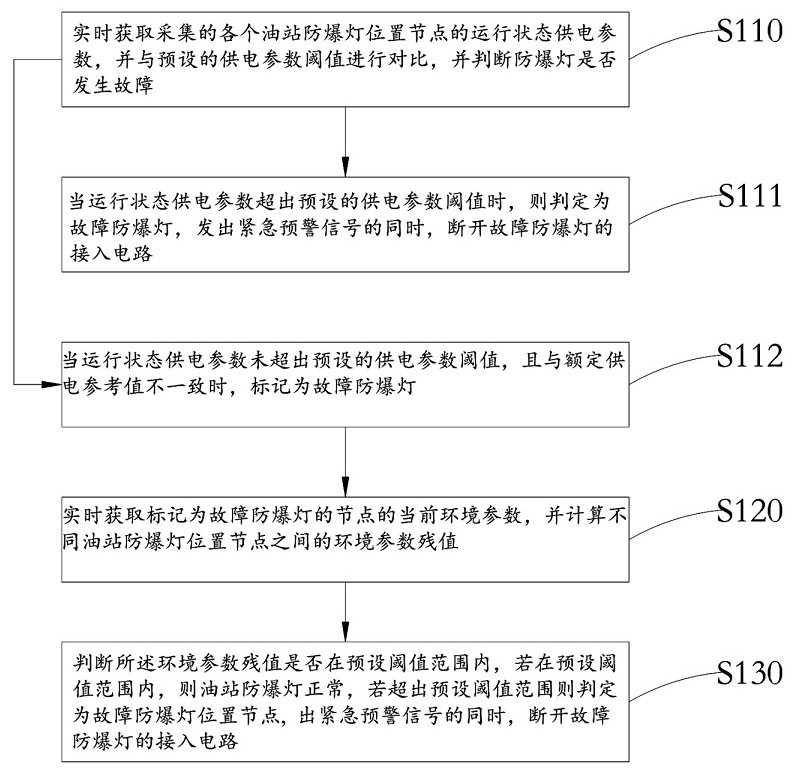

[0066] see image 3 As shown, another embodiment of the present invention also provides an emergency early warning method for explosion-proof lights in gas stations. The emergency warning method specifically includes the following steps:

[0067] S110. Obtain in real time the collected operating state power supply parameters of each gas station explosion-proof lamp position node, and compare with the preset power supply parameter threshold, and determine whether the explosion-proof lamp is faulty;

[0068] S111. When the power supply parameter in the operating state exceeds the preset power supply parameter threshold, it is determined that it is a faulty explosion-proof lamp, and at the same time as an emergency warning signal is sent, the access circuit of the faulty explosion-proof lamp is disconnected;

[0069] S112. When the power supply parameter in the running state does not exceed the preset power supply parameter threshold and is inconsistent with the rated power supp...

Embodiment 3

[0075] see Figure 4 As shown, in one embodiment of the present invention, an emergency warning system for failure of explosion-proof lamps in oil stations is also provided. Emergency early warning, the gas station explosion-proof lamp failure emergency early warning system includes a collection module 301 , a measurement module 302 , a storage module 303 , a processing module 304 and an alarm unit 305 .

[0076] The collection module 301 is configured at each gas station explosion-proof lamp location node, and is used to collect the current environmental parameters of the explosion-proof lamp location node. Among them, the current environmental parameters include sensors for detecting the illuminance, temperature and / or humidity of the explosion-proof lamps installed at each oil station explosion-proof lamp installation node, and the current environmental parameters of the explosion-proof lamp position nodes of each oil station collected in real time are also based on the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com