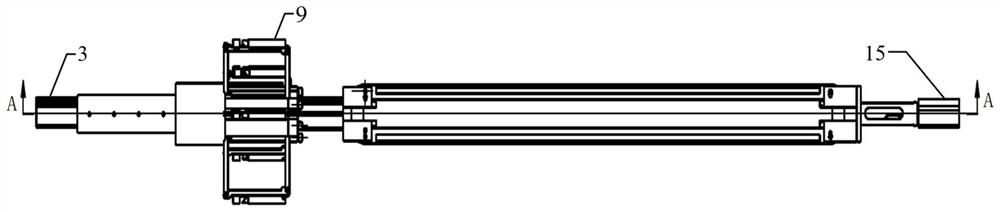

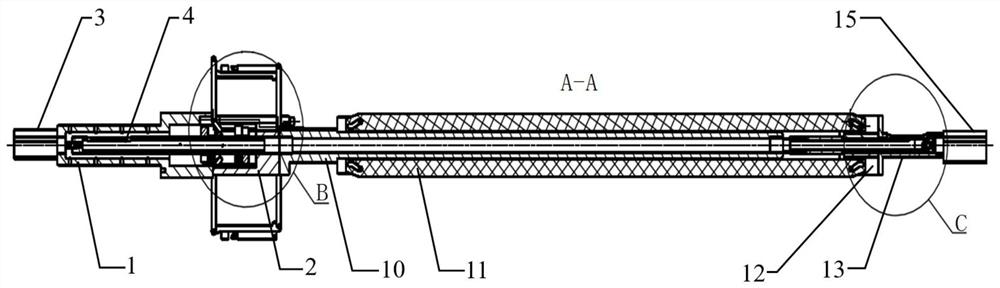

Ultrasonic inspection device for guide clamping hole of guide cylinder of control rod

A technology of inspection device and guide cylinder, applied in the direction of reducing greenhouse gas, climate sustainability, reactor, etc., can solve problems such as control rod sticking risk, etc., and achieve the effect of improving inspection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

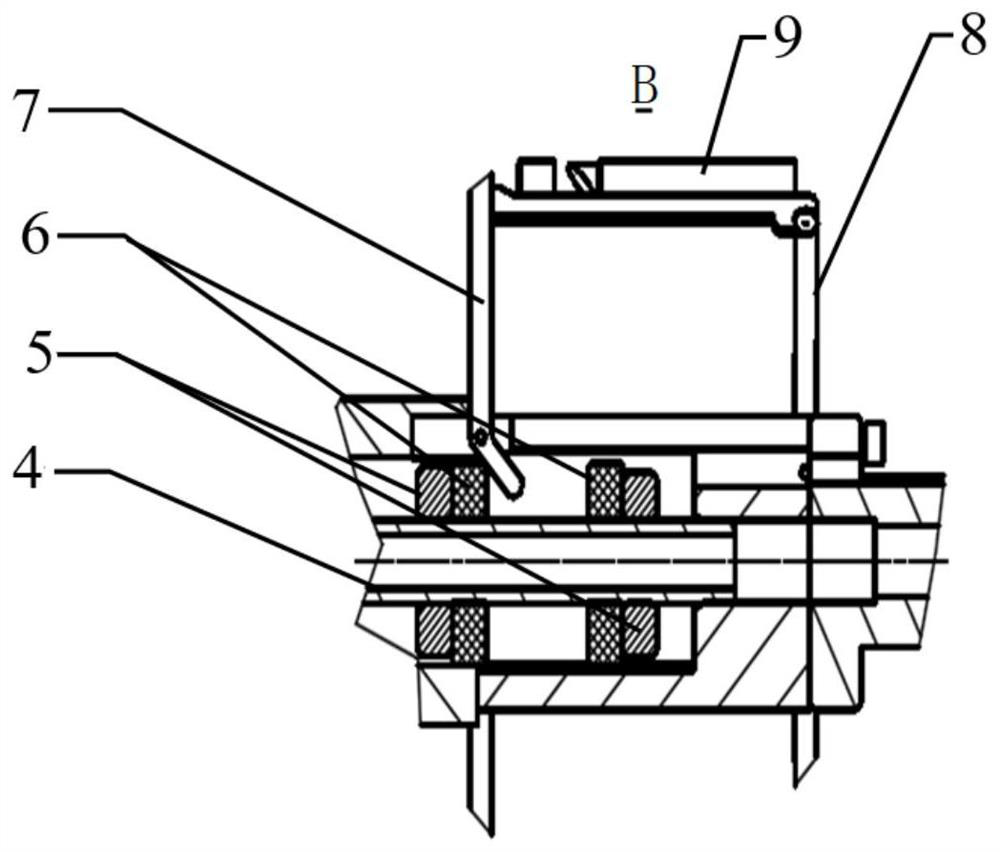

Method used

Image

Examples

Embodiment Construction

[0038] Although the control rod guide cylinder guide stuck hole ultrasonic inspection device of the present invention can be implemented in many different ways, this article will describe the exemplary implementation in detail with reference to the accompanying drawings, and it should be understood that the description herein should be considered as The structure of the control rod guide cylinder guide stuck hole ultrasonic testing device is illustrated without intending to limit the protection scope of the present invention to the exemplary embodiment. Accordingly, the drawings and description of the detailed description are to be considered as illustrative in nature of the invention and not as limiting.

[0039] In the description of the present invention, it should be noted that the terms "upper", "lower", "left", "right", "inner", "outer", "horizontal", "vertical" etc. herein indicate The orientation or positional relationship is based on the orientation or positional rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com