Swivel joint and operation machine

A technology for rotary joints and working machinery, applied in the direction of connection, rotating current collectors, current collectors, etc., can solve the problems of easy damage of electric slip rings, high maintenance cost and high cost of electric slip rings, and achieves reduction of processing costs and simple structure. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

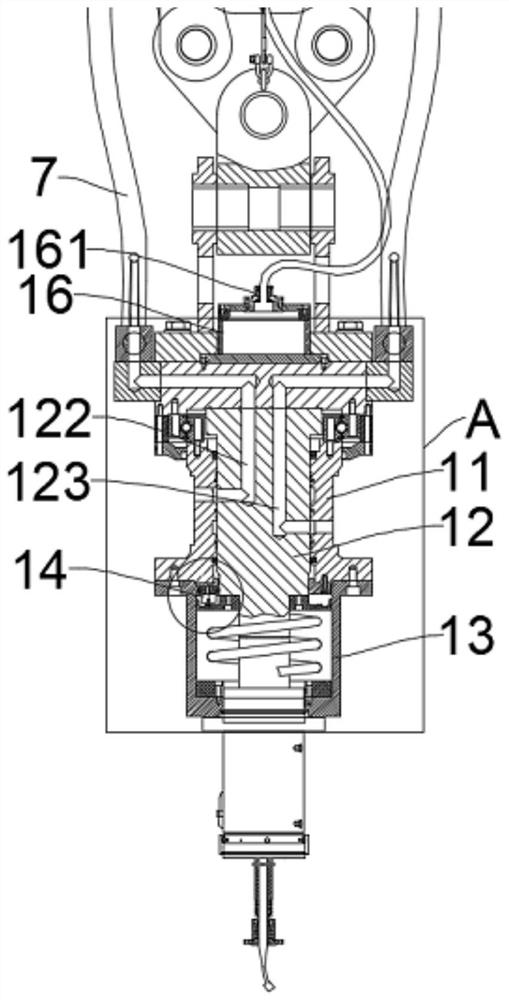

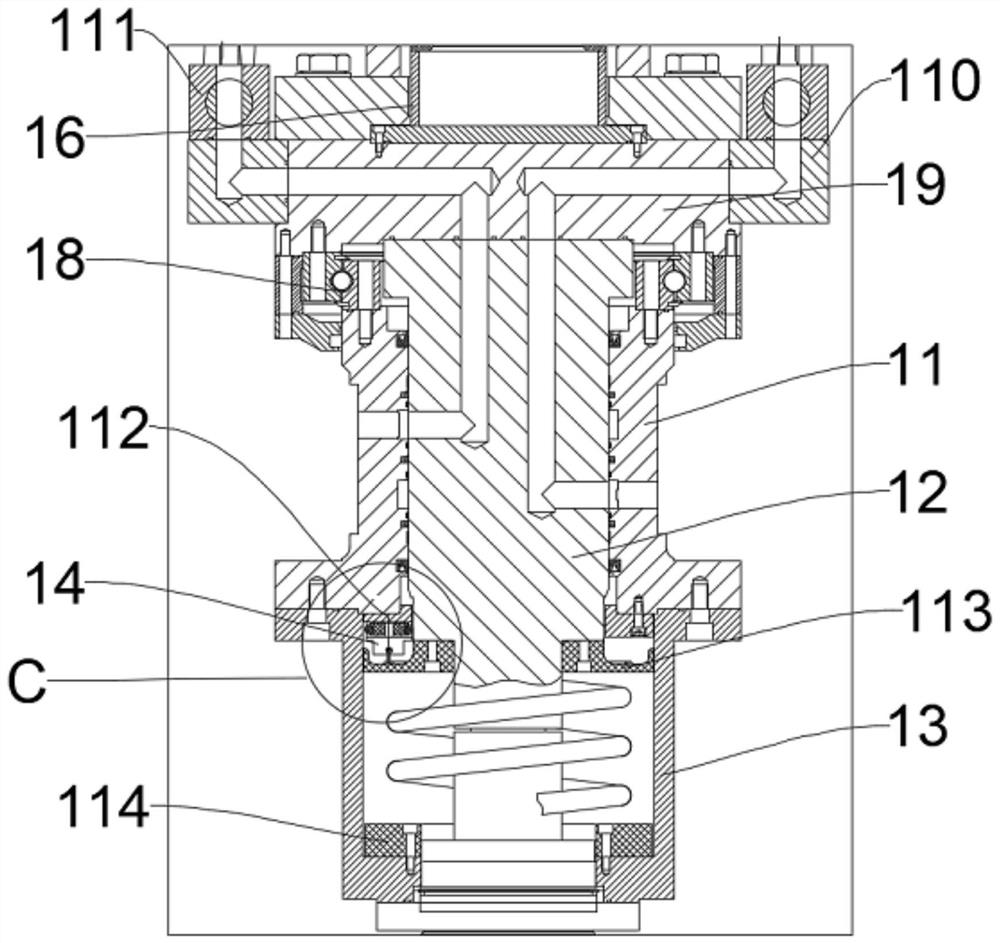

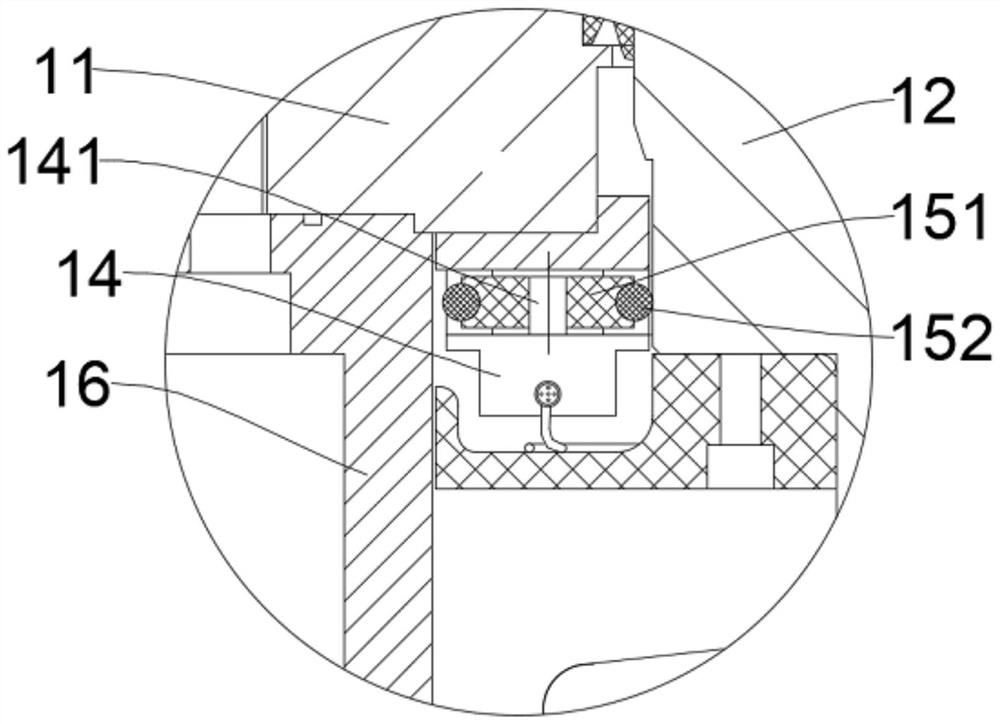

[0039] This embodiment provides a rotary joint 1, such as Figure 1 to Figure 5 As shown, it includes a shaft sleeve 11, a main shaft 12 and a wire storage box 13. Among them, the shaft sleeve 11 is set outside the main shaft 12, and the main shaft 12 is rotatably arranged in the shaft sleeve 11; the main shaft 12 is provided with a wire hole 121; the wire storage box 13 is fixedly connected to the shaft sleeve 11; the wire storage box 13 There is an accommodating chamber for storing the cables 5, and the wire storage box 13 is provided with a first outlet 131 communicating with the accommodating chamber.

[0040]When the swivel joint 1 of this structure is used, it is connected to the working device 2, and the cable 5 is passed through the wire hole 121 of the main shaft 12 and the wire storage box 13, and a section of loose cable 5 is stored in the wire storage box 13. , when the main shaft 12 rotates relative to the shaft sleeve 11, the wire storage box 13 is fixed relativ...

Embodiment 2

[0061] This embodiment provides a working machine, such as Figure 6 and Figure 7 As shown, it includes the rotary joint 1 and the working device 2 in the first embodiment, and the shaft sleeve 11 is connected to the working device 2 .

[0062] For the working machine with this structure, the cable 5 in the junction box 16 can rotate with the cable 5 inside the main shaft 12, providing a turning margin for the relative rotation of the upper and lower cables 5, preventing the cable 5 from twisting itself, effectively protecting the cable 5, and preventing the cable 5 from being damaged. and the slack section cable 5 is located in the wire storage box 13, and will not be wound and scratched against the external mechanism of the wire storage box 13, so as to effectively protect the cable 5 and prolong the service life of the cable 5. The swivel joint 1 accommodates a section of slack cable 5 through the wire storage box 13 to provide a swivel margin for the relative rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com