Permanent magnet motor rotor device

A permanent magnet motor and rotor technology, applied in electromechanical devices, magnetic circuit rotating parts, magnetic circuits, etc., can solve problems affecting the stable operation of the rotor, complex rotor structure, damage to parts, etc., to achieve effective lightweight and general use Good performance, ensure the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

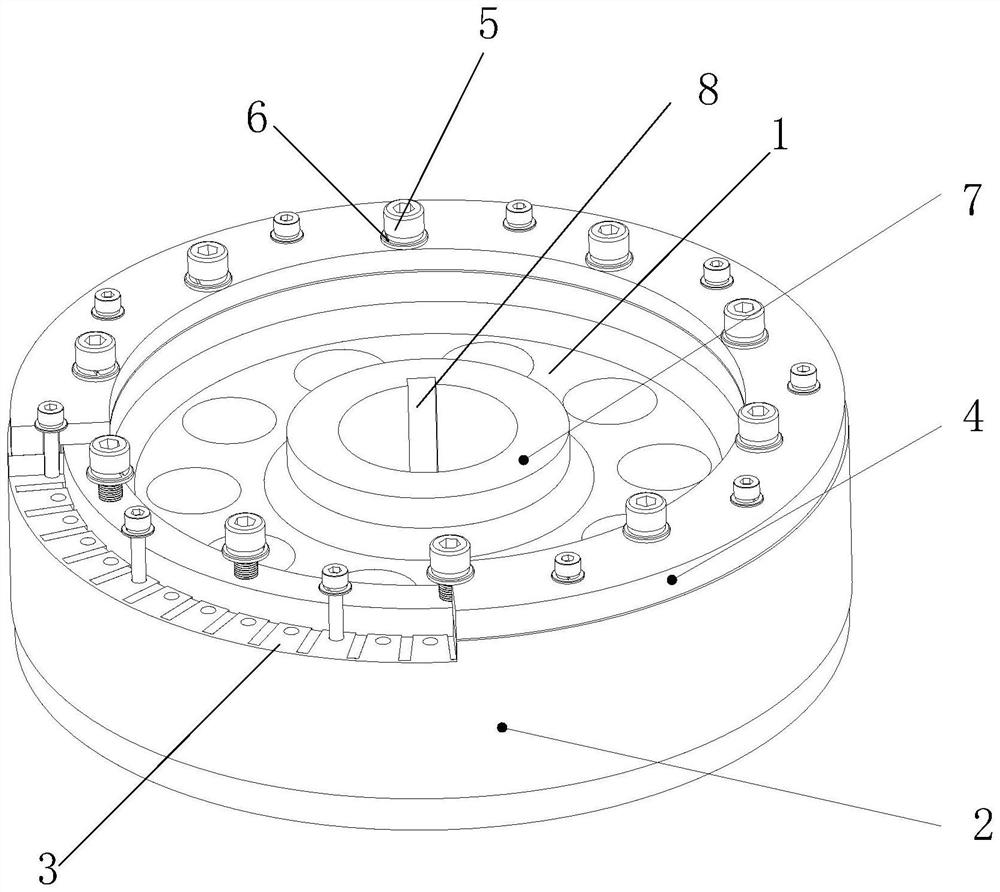

[0030] like figure 1 A rotor device of a permanent magnet motor, including a hub 1, which is different in that: the periphery of the hub 1 is bonded with a ring-shaped silicon steel sheet 2, which satisfies the firm combination of the two. At the same time, considering the normal operation needs, several permanent magnets 3 are distributed on the upper end of the annular silicon steel sheet 2 . In order to satisfy stable installation, a positioning component is arranged between the permanent magnet 3 and the annular silicon steel sheet 2 . Moreover, in order to carry out stable positioning, the permanent magnet 3 is covered with a magnetic steel end plate 4 . Considerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com