Aviation aluminum foil meal box recovery device

A recycling device and aluminum foil technology, applied in transportation and packaging, presses using rotating pressure components, metal processing, etc., can solve the problems of easy deformation during use and collection, reduction of recycling value, and increase of recycling cost, etc., to achieve convenience Effects of cleaning work, increased cleaning effect, and reduced cleaning difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

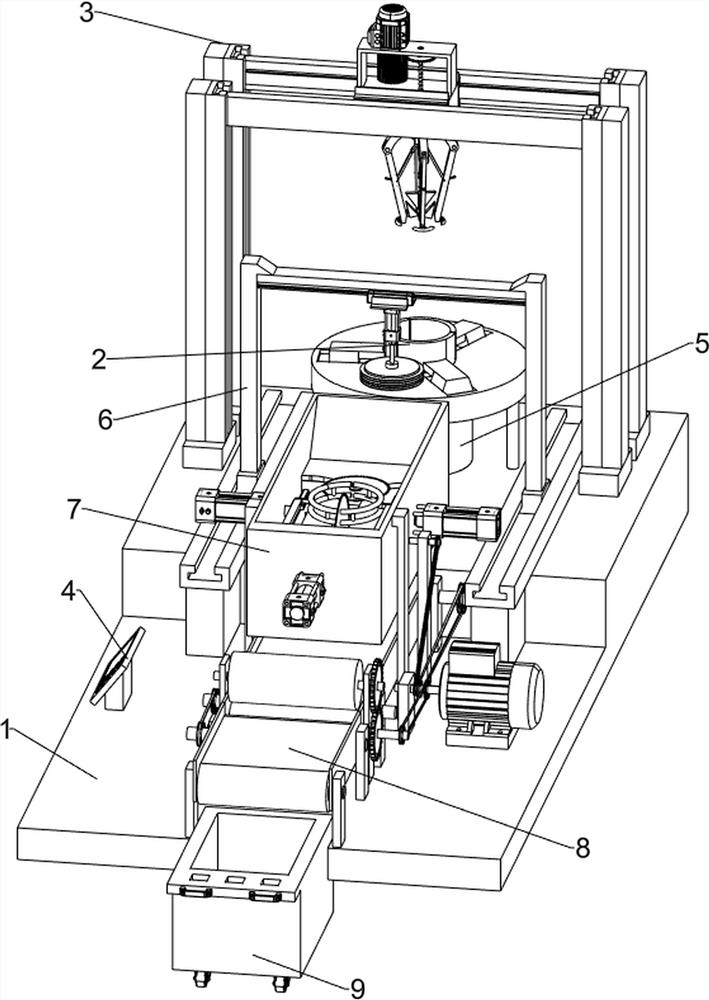

Embodiment 1

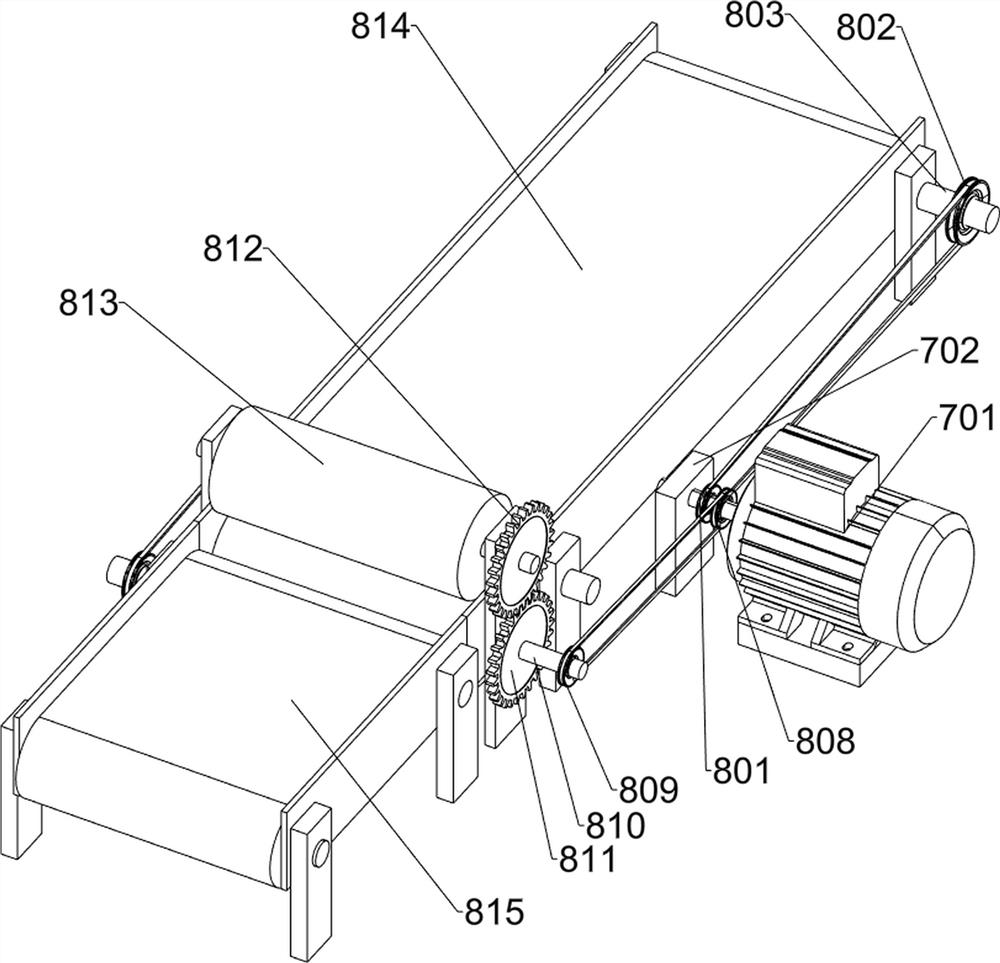

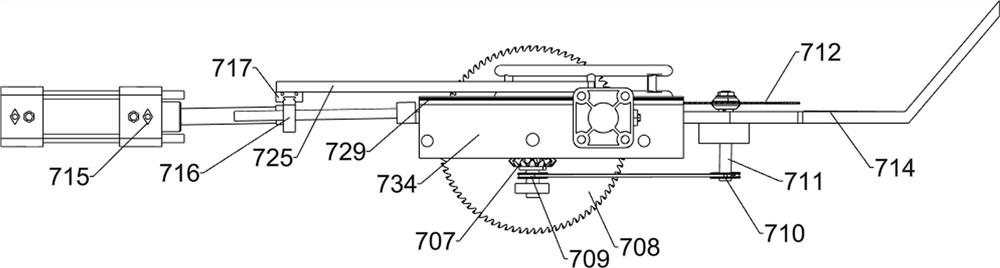

[0035] A kind of recycling device of aluminum foil lunch box for aviation, such as Figure 1-2 As shown, it includes a workbench 1, an electric three-jaw chuck 2, an unfolding system 3, a control panel 4, a support platform 5, a leveling system 6, a cutting system 7, a rolling system 8 and a collecting vehicle 9; An electric three-jaw chuck 2 is arranged on the upper left side; an unfolding system 3 is arranged on the upper left side of the workbench 1, and the unfolding system 3 is located directly above the electric three-jaw chuck 2; Fixed connection; a support platform 5 is installed above the workbench 1; a leveling system 6 is installed above the workbench 1, and the leveling system 6 is located on the right side of the electric three-jaw chuck 2; a cutting machine is installed above the right side of the workbench 1 System 7; a rolling system 8 is installed on the upper right side of the workbench 1, and the rolling system 8 is located below the cutting system 7; a coll...

Embodiment 2

[0038] On the basis of Example 1, such as Figure 1-15As shown, the deployment system 3 includes a first support plate 301, a first electric slide rail 302, a first slide plate 303, a second electric slide rail 304, a second support plate 305, a third electric slide rail 306, and a third support plate 307, the first support frame 308, the first motor 309, the first gear column 310, the first spur gear 311, the first screw mandrel 312, the first connecting frame 313, the second connecting frame 314, the first follower plate 315, The second follower plate 316, the first support block 317, the first follower rod 318, the first wedge block 319, the second wedge block 320, the first transmission rod 321, the first spring 322 and the first C-shaped support ring 323 ; The first support plate 301 is located on the side above the workbench 1; the second support plate 305 is located on the other side above the workbench 1; the first support plate 301 is fixedly connected to the workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com