Laser DED manufacturing control system and method fusing temperature and image information

A technology of image information and manufacturing control, applied in thermometers, additive manufacturing, thermometers with physical/chemical changes, etc., can solve problems that cannot directly reflect the organization and performance of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

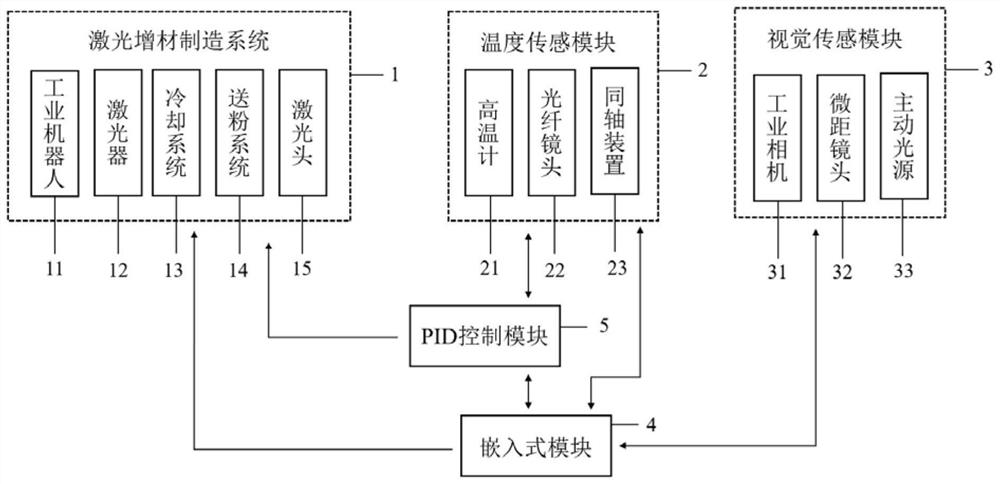

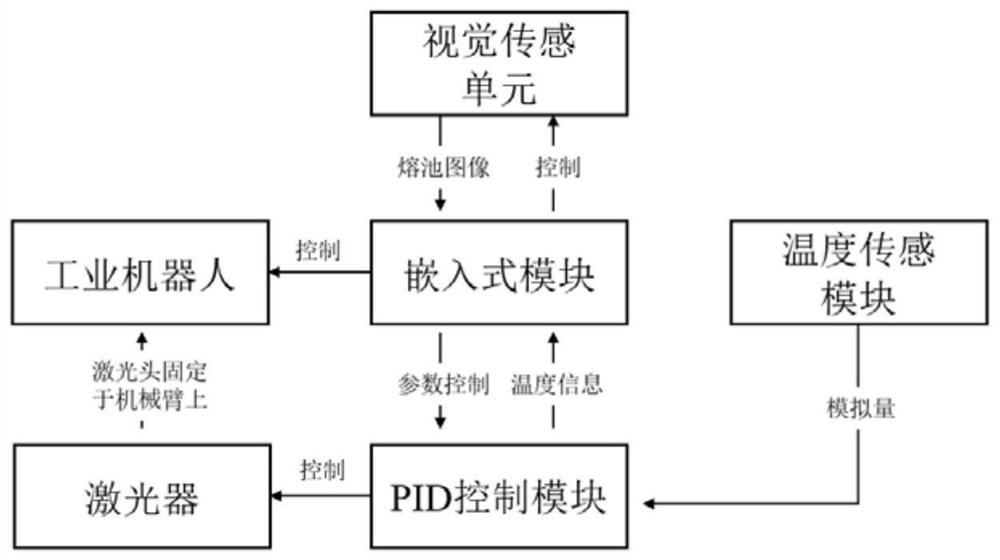

[0050] Such as figure 1 and figure 2 As shown, the present embodiment provides a laser DED manufacturing control system that fuses temperature and image information, including a laser DED manufacturing system 1. The laser DED manufacturing system 1 includes an industrial robot 11, a laser 12 and a laser head 15. The laser DED manufacturing control The system also includes a temperature sensing module 2, a visual sensing module 3, an embedded module 4 and a PID control module 5, the temperature sensing module 2 and the visual sensing module 3 are all fixed on the laser head 15, and are respectively used to generate a molten pool The temperature information and image information of the embedded module 4 are respectively connected to the industrial robot 11, the laser 12, the temperature sensing module 2, the visual sensing module 3 and the PID control module 5;

[0051] The embedded module 4 sets the PID parameters and thresholds of the PID control module 5 according to the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com