Shaft finish machining clamp and shaft machining machine tool

A technology for processing machine tools and fixtures, applied in metal processing machinery parts, manufacturing tools, metal processing equipment and other directions, can solve problems such as low production efficiency, easy wear and tear on the stepped surface of the workpiece, and complicated operations, so as to improve production efficiency, clamp Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

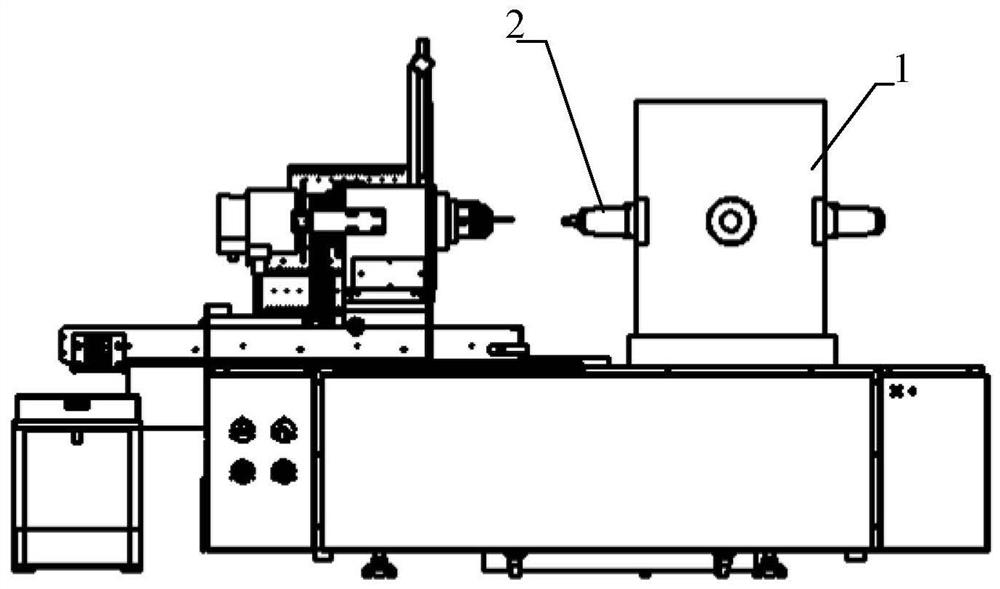

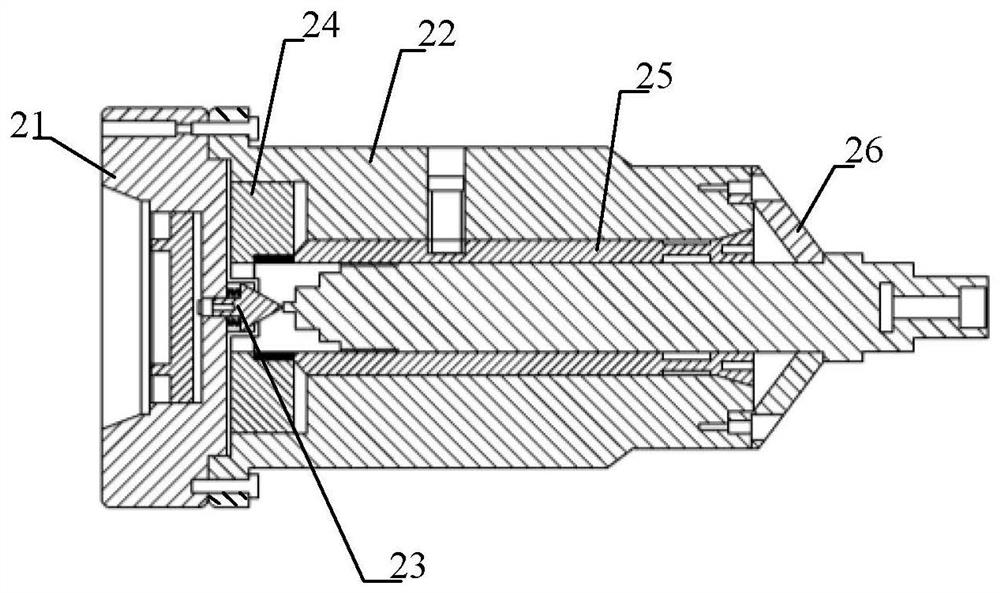

[0029] figure 1 A schematic diagram of the structure of the shaft finishing machine tool in the embodiment of the present invention is shown. The shaft finishing machine tool includes a machine tool body and a shaft finishing device. The shaft finishing machine tool is provided with a shaft finishing device. The shaft finishing device includes A rotating body 1 and a fixture 2, the rotating body 1 is fixed on the shaft processing machine tool, several stations are set on the rotating body 1, and the described Fixture 2.

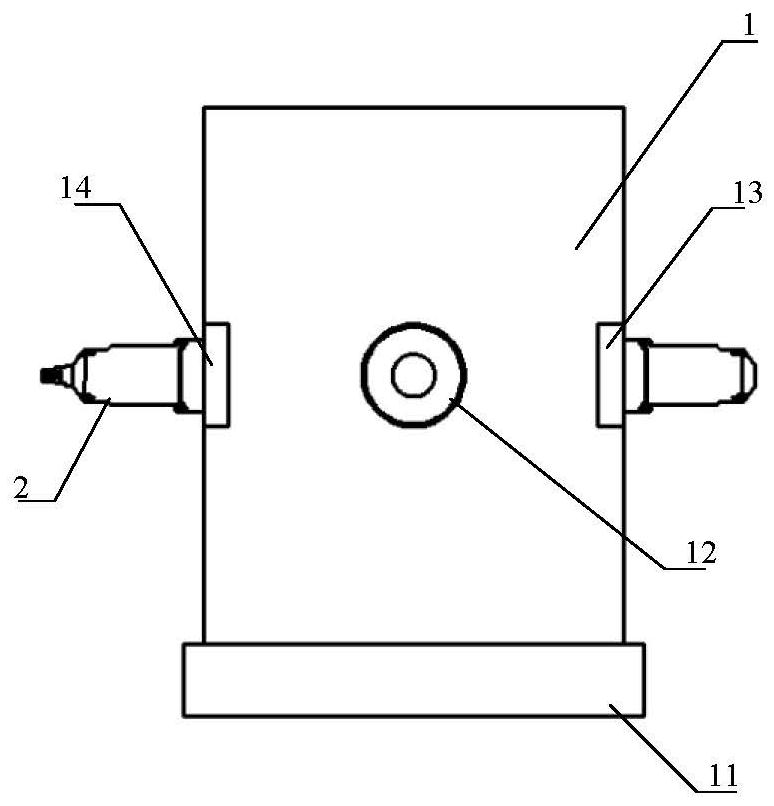

[0030] specific, figure 2 It shows a schematic diagram of the structure of the rotating body in the embodiment of the present invention, the rotating body 1 is fixed on the processing machine tool, the bottom of the rotating body 1 is provided with an indexing plate 11, and the indexing plate 11 ensures the rotation Body 1 rotates to a suitable processing position each time.

[0031] Further, the rotating body 1 is a cylindrical structure, and several sta...

Embodiment 2

[0059] Figure 5 It shows a schematic diagram of the structure of the rotating body in the embodiment of the present invention. The shaft finishing machine tool includes a machine tool body and a shaft finishing device. The shaft finishing machine tool is provided with a shaft finishing device. The shaft finishing device includes a rotating body 1 and a fixture 2, the rotating body 1 is fixed on the shaft processing machine tool, several stations are set on the rotating body 1, and the fixture 2 is arranged on any one of the several stations .

[0060] Specifically, the rotating body 1 is a round table turntable structure, and several stations are arranged on the circumference of the round table end surface of the rotating body 1, and the bottom of the rotating body 1 is provided with an indexing plate 11, and the indexing plate 11 The rotating body 1 can be accurately rotated to a proper position.

[0061] Further, several rotating motors are arranged on the inner circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com