Online intermittent 180-degree high-speed turnover device suitable for flat products

A turning device and intermittent technology, applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of missing or wrong turning, lack of physical strength, distraction, etc., to reduce the transmission speed and reduce work energy consumption , the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

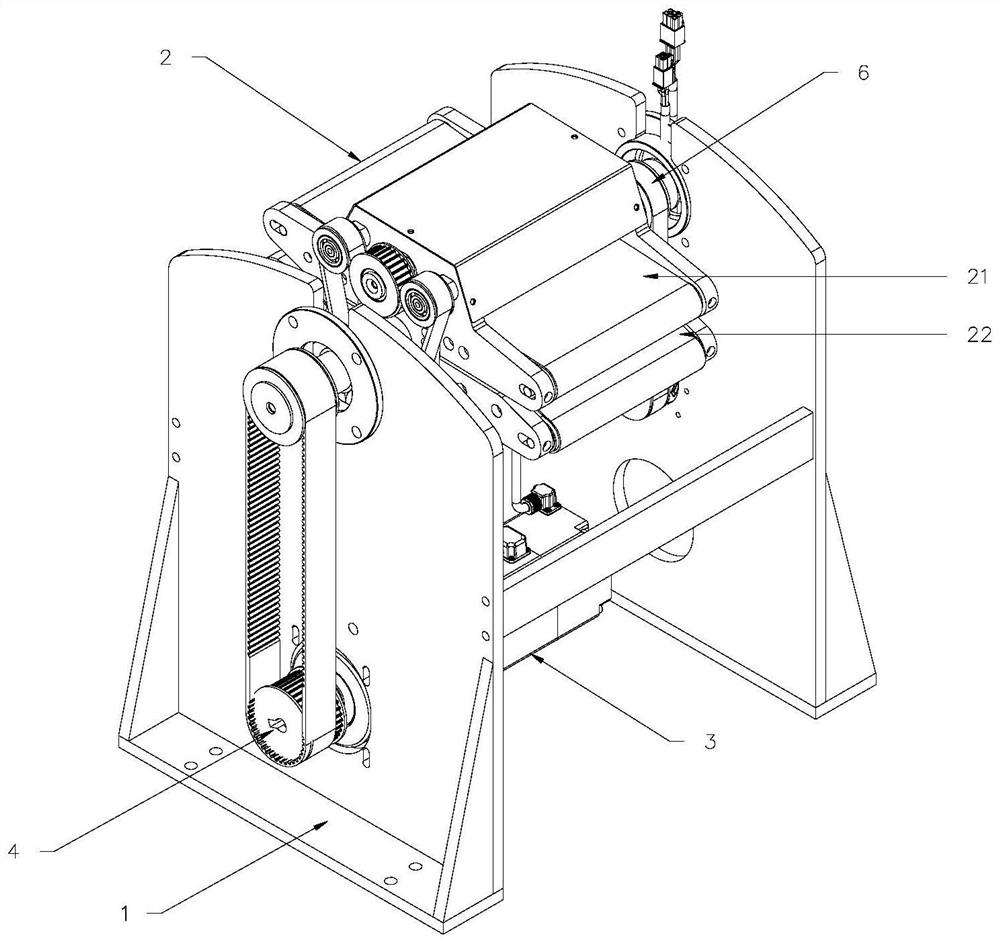

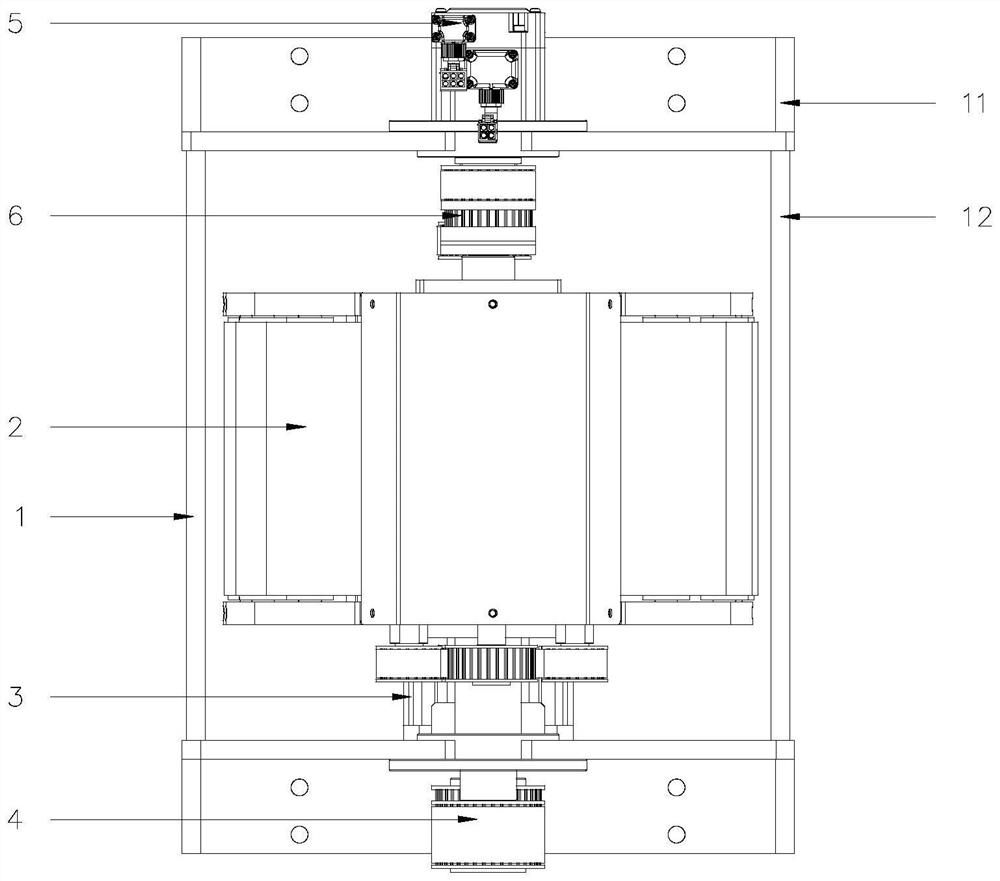

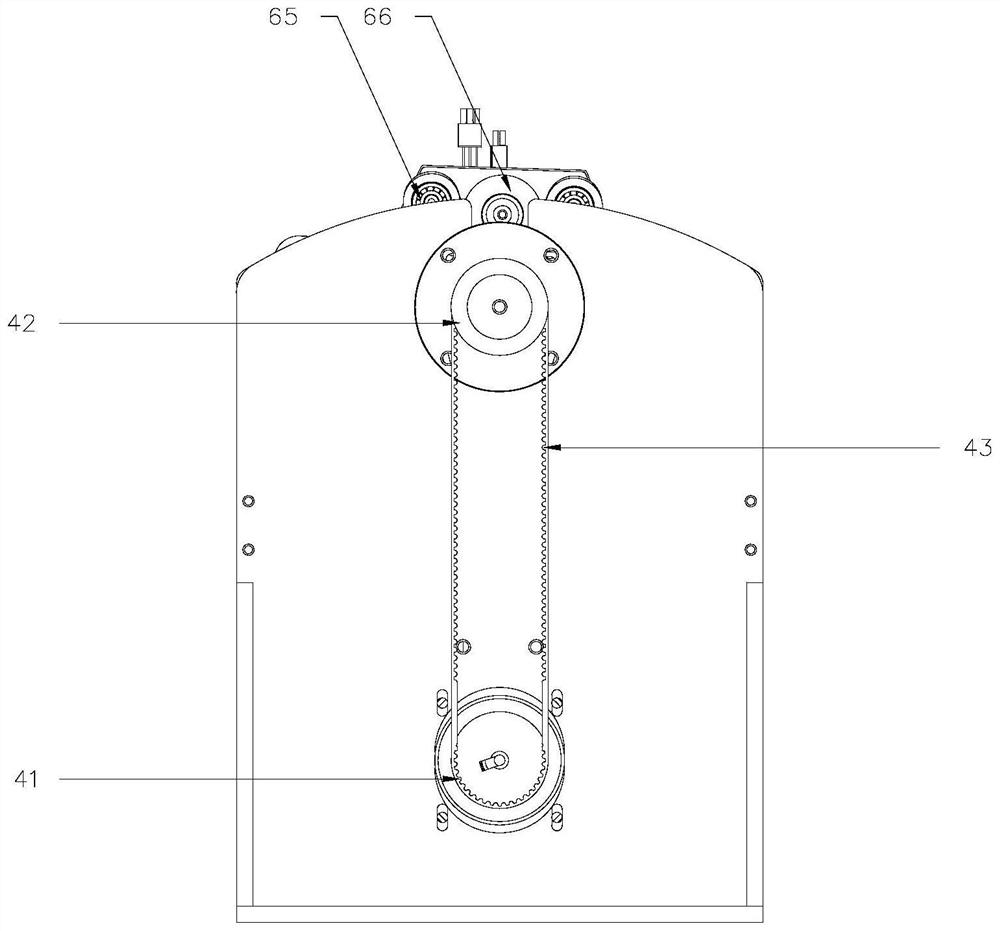

[0021] refer to Figure 1 to Figure 5 , the present invention is an online intermittent 180-degree high-speed turning device suitable for flat products, including a frame 1, a turning plate 2, a main motor 3, a main transmission assembly 4, an auxiliary motor 5, an auxiliary transmission assembly 6 and a controller. The turning disc 2 includes two conveyor belts 21 arranged in parallel and forming a gap 22 for flat products to pass through. The auxiliary motor 5 drives the belt bodies 214 of the two conveyor belts 21 to rotate in opposite directions through the auxiliary transmission assembly 6 at the same time so that The flat product moves along the conveying direction in the gap 22, and the main motor 3 simultaneously drives the two conveyor belts 21 on the frame 1 through the main transmission assembly 4 to rotate the axis perpendicular to the conveying direction in the middle of the gap 22 so that the flat product 180 ° flipping, the controller is electrically connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com