Fire hose winding equipment capable of rapidly winding and avoiding folding of hose

A technology for fire hoses and hoses, which is applied in the delivery of filamentous materials, thin material handling, transportation and packaging, etc. It can solve the problems of increasing the workload of firefighting operations, reducing the efficiency of firefighting operations, and reducing the practical life of hoses. Achieve the effect of improving safety and reliability, reducing workload and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

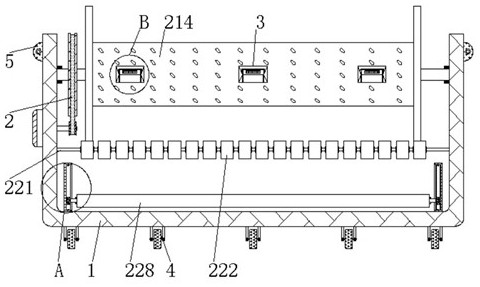

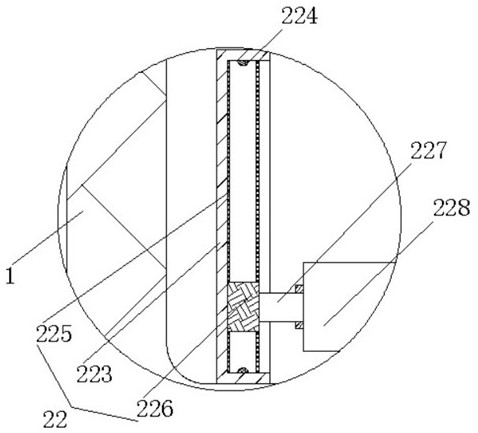

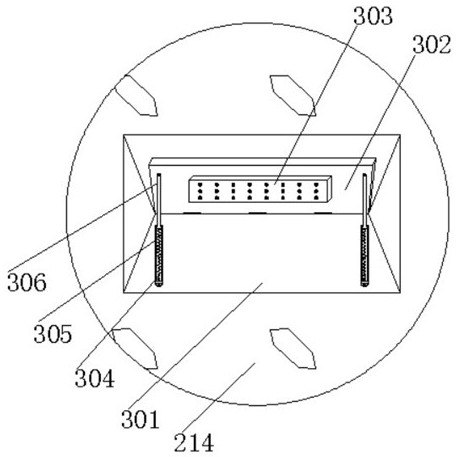

[0022] see figure 1 , image 3 - Figure 4 , a fire hose winding device for fast winding to avoid hose folding, including a support frame 1, the inner side of the support frame 1 is movably connected with a stretch winding mechanism 2, and the stretch winding mechanism 2 includes a hose for winding The collection assembly 21, the leveling assembly 22 used for water discharge inside the hose and the smoothing of the hose body, the collection assembly 21 is movably connected to the inside of the support frame 1, the leveling assembly 22 is movably connected to the inside of the support frame 1, the collection assembly 21 Including motor 211, pulley 212, conveyor belt 213, roll roller 214, runner 215, blocking plate 216, the outside of support frame 1 is fixedly connected with motor 211, the outside of motor 211 is fixedly connected with pulley 212, the outside of pulley 212 The transmission is connected with a conveyor belt 213, the inner side of the support frame 1 is movably...

Embodiment 2

[0026] see figure 1 - Figure 5 , a fire hose winding device for fast winding to avoid hose folding, including a support frame 1, the inner side of the support frame 1 is movably connected with a stretch winding mechanism 2, and the stretch winding mechanism 2 includes a hose for winding The collection assembly 21, the leveling assembly 22 used for water discharge inside the hose and the smoothing of the hose body, the collection assembly 21 is movably connected to the inside of the support frame 1, the leveling assembly 22 is movably connected to the inside of the support frame 1, the collection assembly 21 Including motor 211, pulley 212, conveyor belt 213, roll roller 214, runner 215, blocking plate 216, the outside of support frame 1 is fixedly connected with motor 211, the outside of motor 211 is fixedly connected with pulley 212, the outside of pulley 212 The transmission is connected with a conveyor belt 213, the inner side of the support frame 1 is movably connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com