Ceramic membrane water filtering device and pretreatment method thereof

A ceramic membrane and pretreatment technology, applied in filtration treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as methods that do not form a system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

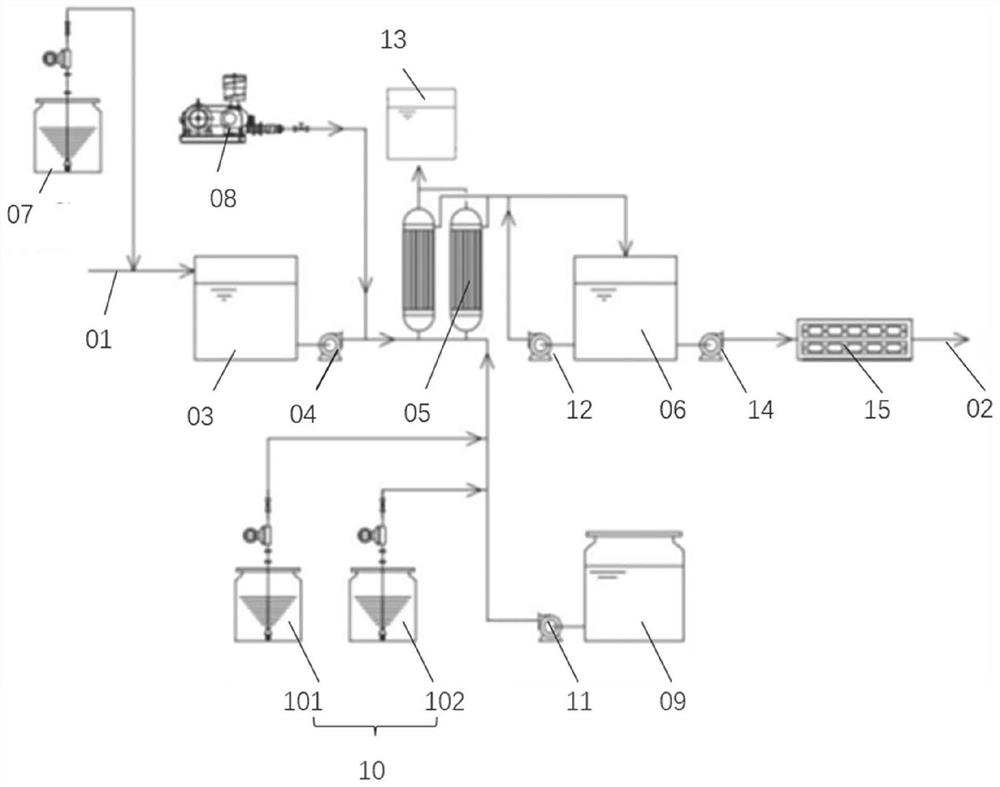

Embodiment 1

[0059] Raw water sampling: Qingdao Jiaozhou Bay seawater, turbidity 24.7NTU, conductivity 55850μS / cm, pH7.78, total hardness 6126mg / L calculated as calcium carbonate;

[0060] Selection of ceramic membrane: Haichuan Membrane Zibo Environmental Protection Technology Co., Ltd., the model is CM-12, the pore size is 60nm, the area is 24㎡, and the material is zirconia, alumina and titanium oxide composite materials; the ceramic membrane adopts cross-flow filtration, cross-flow 10%, the transmembrane pressure difference is 0.08MPa, and the operating flux is 5.6m 3 / h;

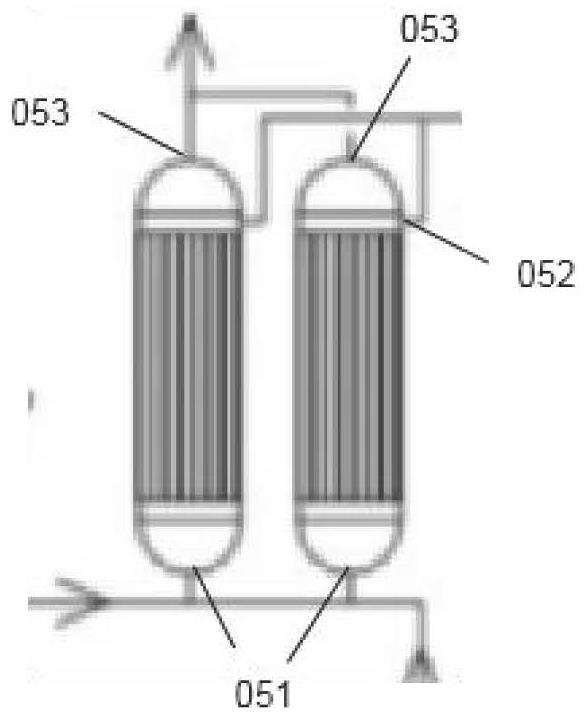

[0061] Pretreatment method: Seawater enters the water inlet pipe 01, and 10 mg / L flocculant is quantitatively added through the flocculant adding device 07. After the seawater enters the flocculation reaction tank 03 and reacts for 30 minutes, it is pressurized by the first booster pump 04 and then pumped by the water inlet 051 After entering the ceramic membrane filter 05, after being filtered by the ceramic membra...

Embodiment 2

[0065] With embodiment 1, difference is not to add flocculant;

[0066] After 8 hours of operation, the transmembrane pressure rises to 0.13MPa, and chemical cleaning is required, and the cleaning cycle is 3 times a day.

Embodiment 3

[0068] Same as Example 1, the difference is that 3mg / L flocculant is added, and the transmembrane pressure rises to 0.13MPa after 24 hours of operation, and chemical cleaning is required, and the cleaning cycle is once a day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Total hardness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com