Preparation method of black cotton-like fiber

A technology of imitating cotton fiber and black color, which is applied in the field of preparation of black imitating cotton fiber, can solve the problems of tow performance impact, reduced service life of yarn guide, and large tow tension, so as to improve the network degree of tow and avoid resources Loss, not easy to break the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

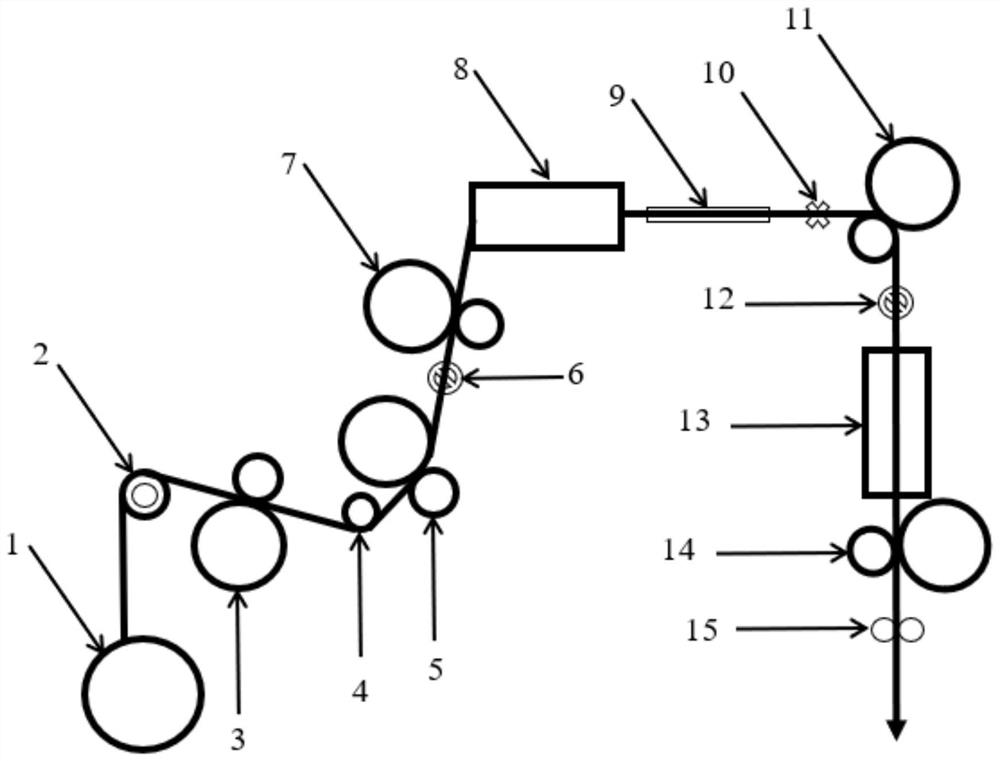

Method used

Image

Examples

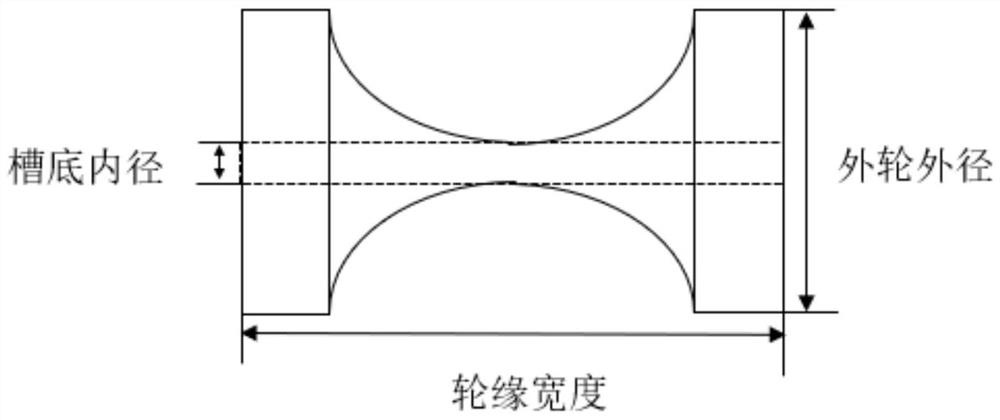

Embodiment 1

[0042] A kind of preparation method of black imitation cotton fiber, adopt above-mentioned DTY texturizing process, wherein, the specifications of polyester POY and polyester FDY fiber are all 120dtex / 96f, carbon black content is 1.2wt%; The first wire guide is guide wire The wire guide wheel is in contact with the groove bottom of the first wire guide during the movement of the tow, and drives the first wire guide to rotate; the material of the wire guide wheel is ceramic, the surface hardness of the groove bottom is 1500HV, and the friction coefficient between the groove bottom and the tow is is 0.2; if figure 2 As shown, the rim width of the godet wheel is 20mm, the outer diameter of the outer wheel is 9.4mm, and the inner diameter of the groove bottom is 6mm; the tensioner is a magnetic tensioner; the tow is in contact with the groove bottom of the godet wheel attached to the tensioner during movement ;The tension of the tensioner is set to 10cN;

[0043] The process par...

Embodiment 2

[0049] A kind of preparation method of black imitation cotton fiber, adopt above-mentioned DTY texturizing process, wherein, the specifications of polyester POY and polyester FDY fiber are all 120dtex / 96f, carbon black content is 1.3wt%; The first wire guide is guide wire The wire guide wheel is in contact with the groove bottom of the first yarn guide during the movement of the tow, and drives the first yarn guide to rotate; the material of the wire guide wheel is ceramic, the surface hardness of the groove bottom is 1800HV, and the friction coefficient between the groove bottom and the tow is 0.2; the rim width of the godet wheel is 20mm, the outer diameter of the outer wheel is 9.4mm, and the inner diameter of the groove bottom is 6.2mm; contact; the tension of the tensioner is set to 9.2cN;

[0050] The process parameters are: pre-screen nozzle air pressure 2.6bar, pre-screen nozzle aperture 1.5mm, first deformation hot box temperature 178°C, shaping hot box temperature 15...

Embodiment 3

[0054] A kind of preparation method of black imitation cotton fiber adopts above-mentioned DTY texturizing process, wherein, the specifications of polyester POY and polyester FDY fiber are all 120dtex / 96f, and carbon black content is 1.4wt%; , the tow is in contact with the groove bottom of the first wire guide during its movement, driving the first wire guide to rotate; the material of the wire guide wheel is ceramic, the surface hardness of the groove bottom is 1880HV, and the friction coefficient between the groove bottom and the tow is 0.22; the rim width of the godet wheel is 23mm, the outer diameter of the outer wheel is 10.2mm, and the inner diameter of the groove bottom is 7mm; the tensioner is a magnetic tensioner; the tow is in contact with the groove bottom of the godet wheel attached to the tensioner during movement; The tension of the tensioner is set to 8.7cN;

[0055] The process parameters are: pre-screen nozzle air pressure 2.8bar, pre-screen nozzle aperture 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com