Hydraulic transmission system controlled by electro-hydraulic proportional valve

An electro-hydraulic proportional valve and hydraulic transmission technology, which is applied to fluid pressure actuation system components, fluid pressure actuation devices, lifting devices, etc., can solve problems such as impact wear and limited cushioning effect of gearbox clutches, and reduce the failure rate , Structural hardware structure is simple and compact, and the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

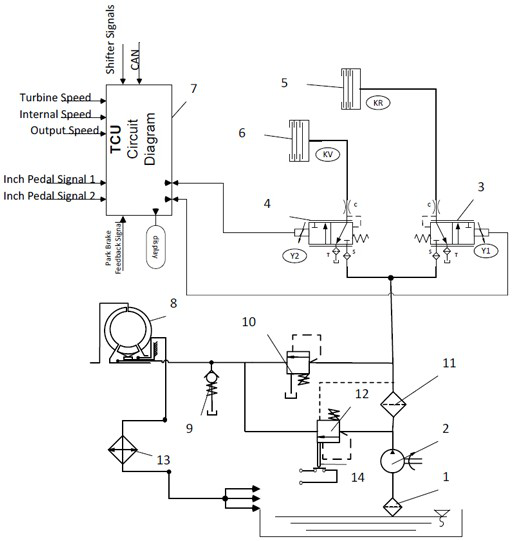

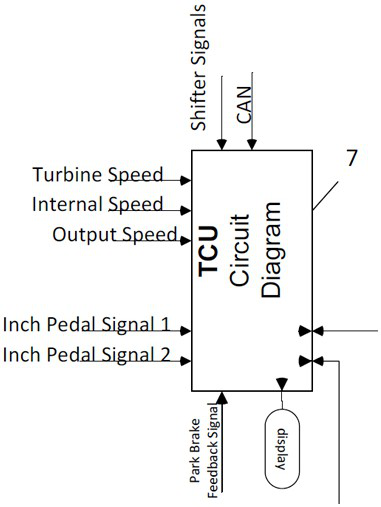

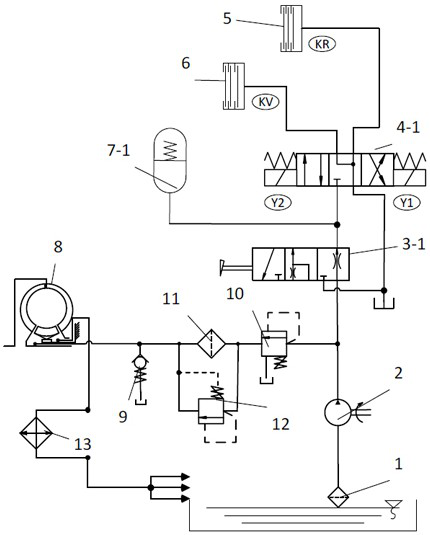

[0025] Such as Figure 1-2 As shown, a hydraulic transmission system controlled by an electro-hydraulic proportional valve in this embodiment, the transmission system includes a coarse oil filter 1, an oil supply pump 2, an electro-hydraulic proportional valve I3, an electro-hydraulic proportional valve II4, a reverse clutch 5, Forward gear clutch 6, transmission controller TCU7, torque converter 8, safety valve 9, main pressure regulating valve 10, fine filter 11, fine oil filter bypass valve 12, radiator 13, pressure switch 14;

[0026] Described transmission system operation comprises the steps:

[0027] The oil in the oil pan enters the inlet of the oil supply pump 2 after passing through the coarse oil filter 1;

[0028] After being pressurized by the operation of the oil supply pump 2, it is filtered by the fine filter 11; and then the oil pressure is further stabilized and controlled through the pressure regulation of the main pressure regulating valve 10;

[0029] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com