Cleaning and oil changing equipment for mining speed reducer and using method of cleaning and oil changing equipment

A speed reducer and cleaning oil technology, which is applied in the direction of mechanical equipment, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of incomplete cleaning, inconvenient and unsafe operation methods, and achieve convenient transportation, movement, The effect of convenient operation and high safety of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, technical solutions and beneficial effects clearer, the present invention will be described in detail below in conjunction with the accompanying drawings.

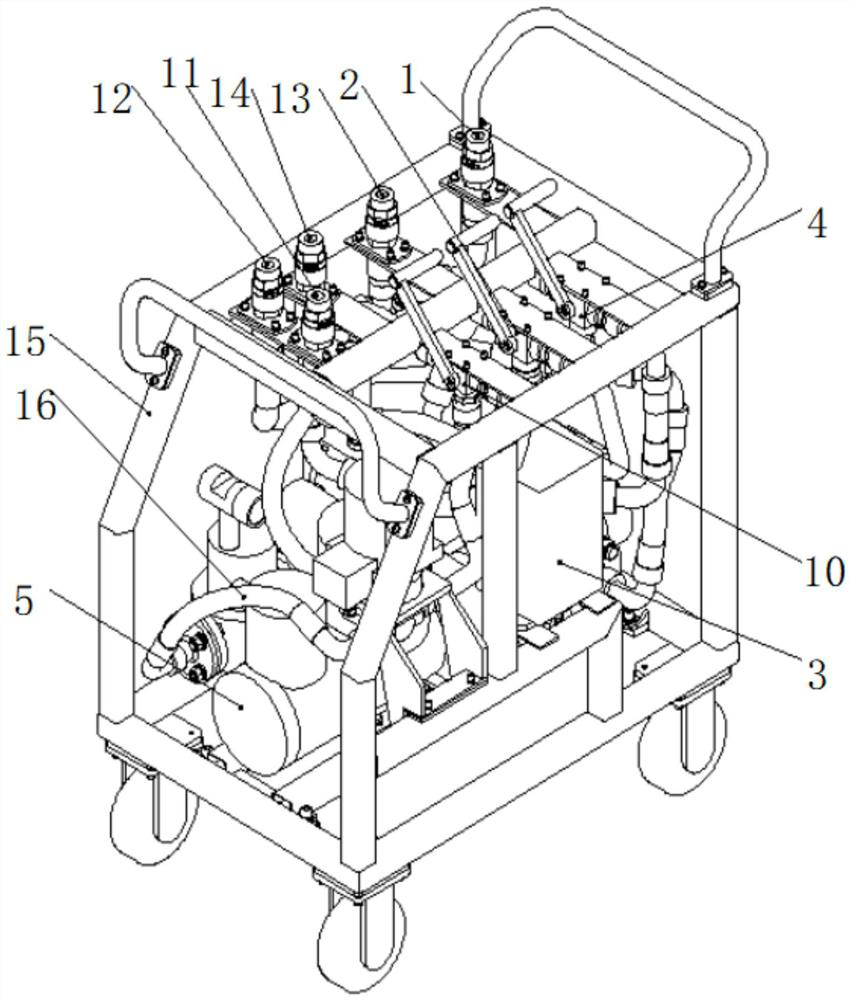

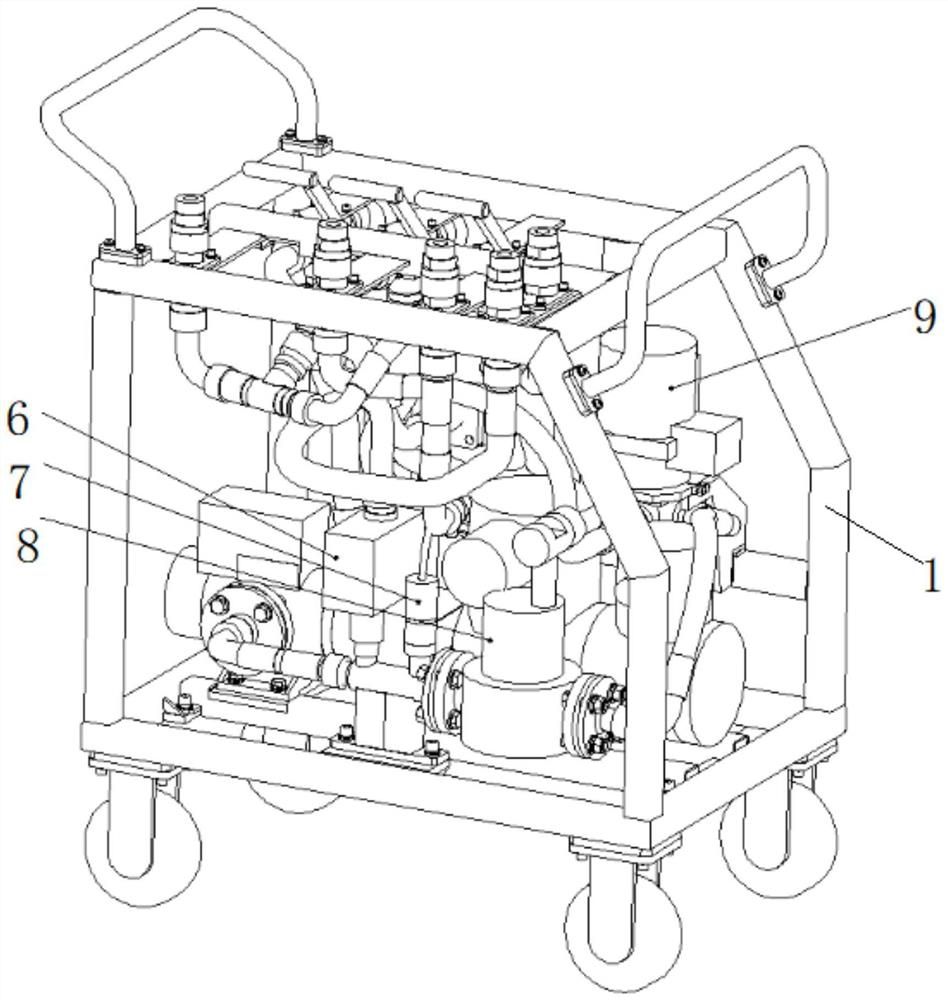

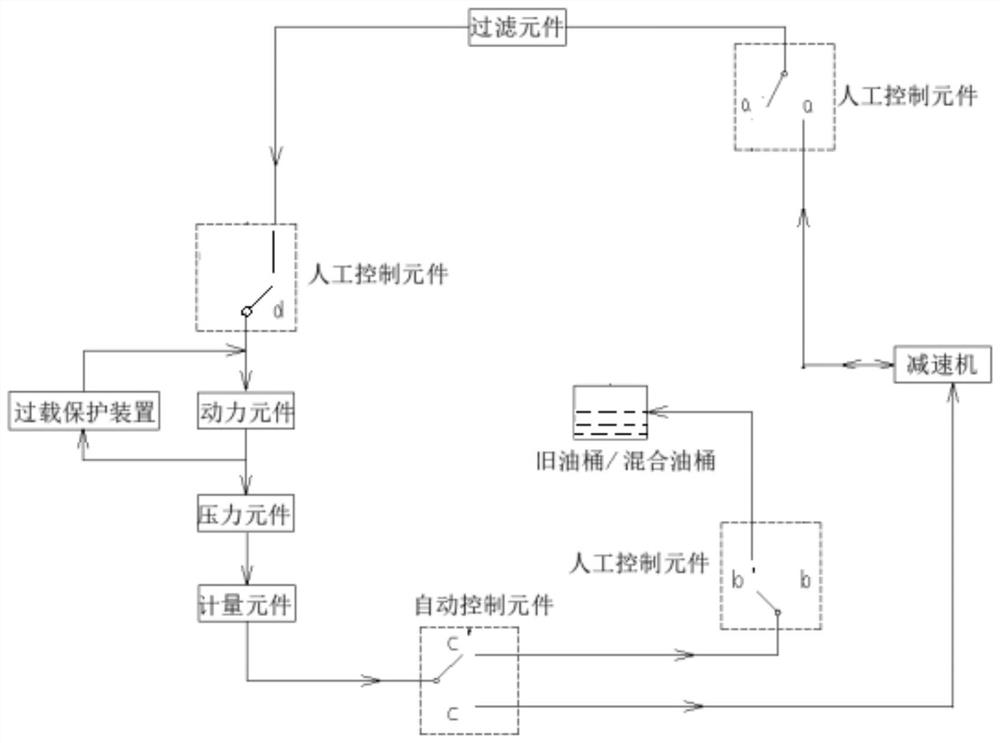

[0031] Such as Figure 1-3 As shown, the mine reducer cleaning and oil change equipment mainly includes a frame assembly 15, a reducer oil discharge port interface 1, a first manual control element 2, a filter element 3, a second manual control element 4, a power element 5, Overload protection device 6, pressure element 7, metering element 8, automatic control element 9, third manual control element 10, old oil barrel interface 11, cleaning oil interface 12, refueling port interface 13 of reducer, new oil interface 14, frame Assembly 15, pipeline assembly 16; the bottom of the frame assembly 15 is provided with universal wheels, the frame assembly 15 is provided with a push handle, and the oil discharge port interface 1 of the reducer is provided on the top of the frame assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com