Winding reinforcement type environment-friendly material core material modular assembly pipeline and manufacturing method

An environmentally friendly material and reinforced technology, applied in the direction of thermal insulation protection of pipelines, pipeline protection, heat preservation, etc., can solve problems such as cracking of joints and affecting the life of pipelines, to prevent cracking of joints, good suitability, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

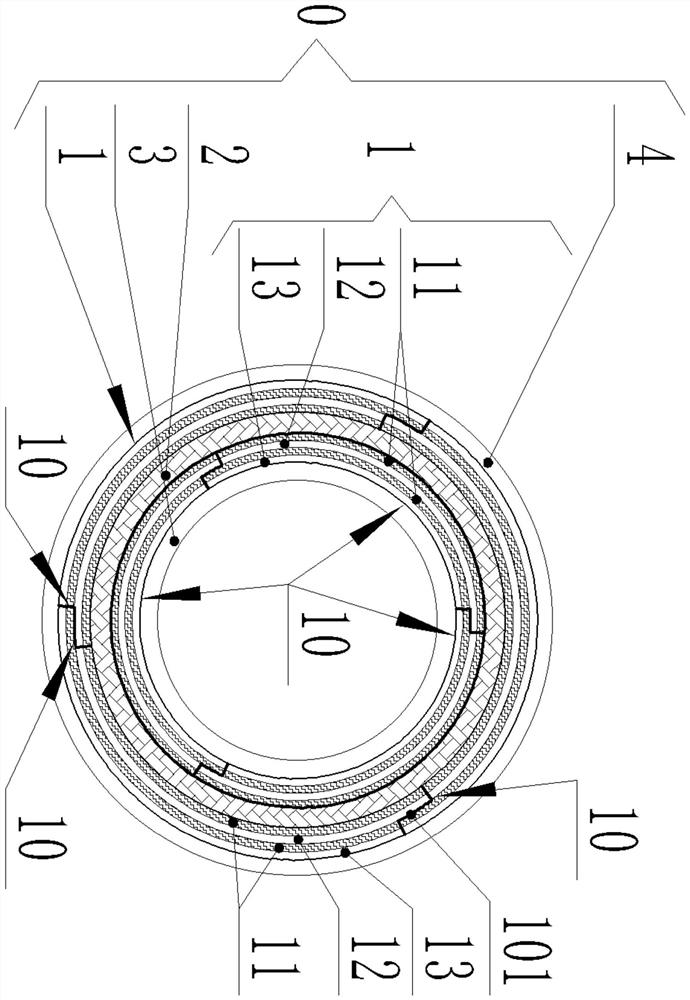

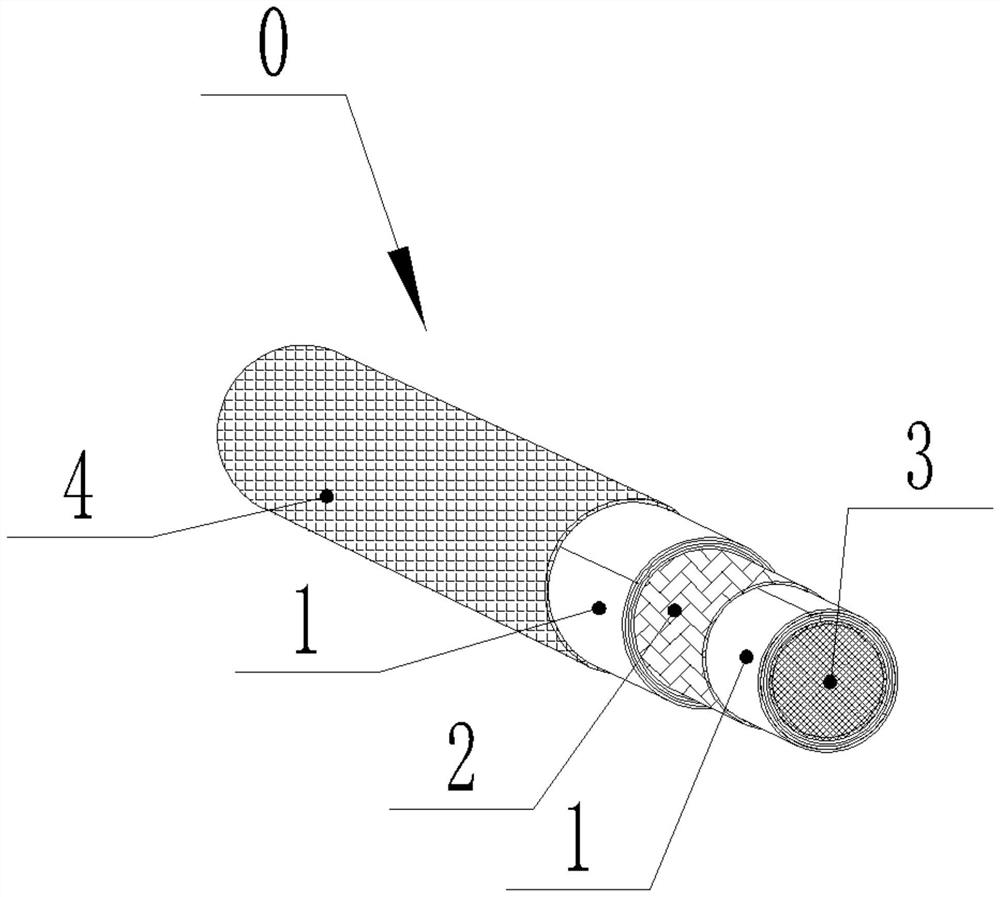

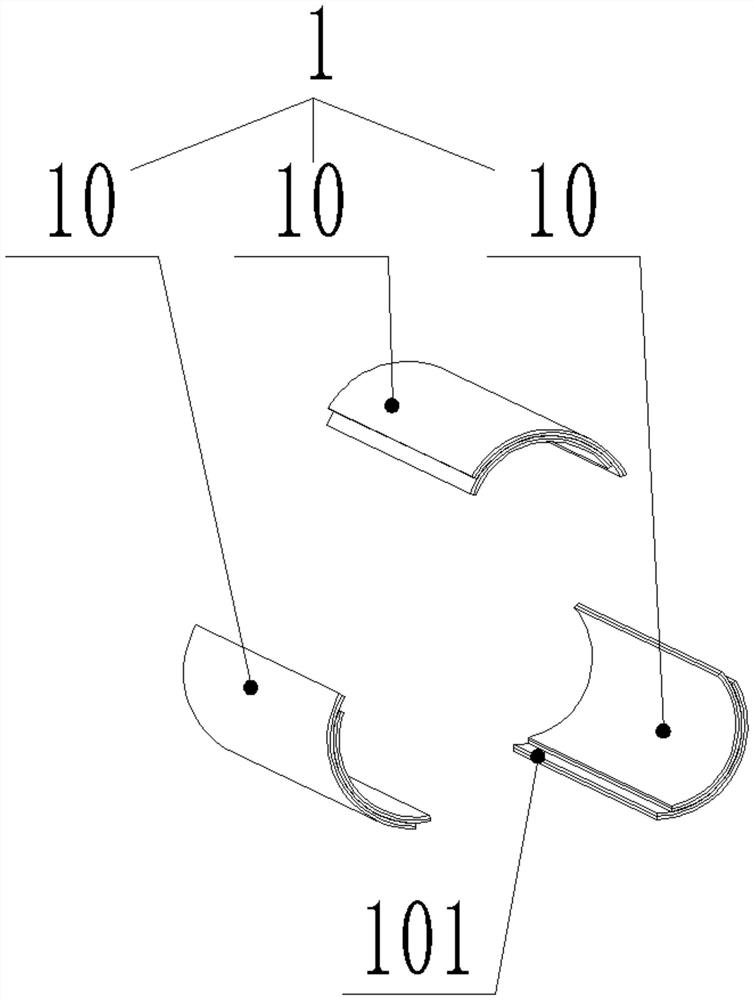

[0036] combine figure 1 , figure 2 and image 3 The shown one kind of winding reinforcement type environmental protection material core material modularized assembled pipeline comprises pipeline body 0, and the cross section of described pipeline body 0 is circular, and the pipeline body 0 comprises two layers of core material layer 1, and the core material Layer 1 includes two layers of environmental protection layers 11 and one layer of reinforcement layer 12, a layer of reinforcement layer 12 is arranged between two adjacent layers of environmental protection layers 11, and the core material layer 1 is composed of three core material module pieces 10 along the side The materials of the core material module assembly 10 correspond to the materials of each layer of the core material layer 1; In addition, the core material layer 1 of the inner layer also includes a functional layer 13, and the functional layer 13 is arranged on the innermost layer of the core material layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com