Styrene and halogenated styrene copolymer and preparation method and application thereof

A halogenated styrene and copolymer technology, applied in the field of functionalized polymer materials, can solve the problem that it is difficult to achieve the flame retardant effect of low-molecular-weight flame retardants, the addition amount is limited, and the flame retardant effect is difficult to surpass the resistance of hexabromocyclododecane. problems such as combustion effect, to achieve the effect of reducing migration, reducing additives, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0033] Table 2: The formulation amount and process conditions of Examples 1 to 12, the units are parts by weight

[0034]

[0035] The nucleating agent in the table is wax, and the foaming agent is pentane.

Embodiment 1、5

[0037] The raw materials and their consumptions used in the embodiments of the present invention are shown in Table 2.

[0038] Among them, Example 1 and Example 5 adopt the following method: In the reactor, add deionized water and dispersant according to the formula in Table 2, start stirring and heat up to 50~70°C to completely dissolve the dispersant; Mixed solution of brominated styrene and styrene monomer dissolved in initiator, nucleating agent wax (preferably polyethylene wax) and flame retardant (when the addition of brominated styrene monomer is less than 0.8%, add HBCD , to increase the bromine content, as in Example 1) into the reactor, heated to 80 ~ 100 ℃, polymerization reaction 2 ~ 24 hours; seal the reactor, then slowly inject blowing agent pentane, after the injection is complete, mechanically Stir, slowly raise the temperature (about 2~3 hours) to 120~130°C, after complete polymerization, lower to normal temperature, open the cover, and obtain expandable poly...

Embodiment 2~4、6~7

[0039] Embodiment 2~4, 6~7, 9~10, 12

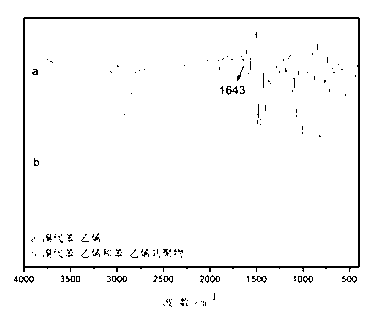

[0040]The raw materials, dosage and reaction temperature are shown in Table 2. The specific method is as follows: In the reaction kettle, add deionized water and dispersant according to the formula in Table 2, start stirring and raise the temperature to 50~70°C to make the dispersant completely Dissolve; mix solution of brominated styrene, styrene monomer and chlorinated styrene monomer dissolved in initiator, nucleating agent wax (preferably polyethylene wax) and flame retardant (when brominated styrene monomer When the addition amount is less than 0.8%, HBCD is added to increase the bromine content, such as in Examples 2 and 3) into the reactor, heated to 80~100°C, cooled after 2~24 hours of polymerization, and filtered to obtain benzene Ethylene and brominated styrene copolymer pellets, such as figure 1 Shown is the infrared spectrum comparison chart of the copolymer (copolymer of bromostyrene and styrene) prepared in Example 10 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com