Method for measuring three-dimensional mass center of super-long large vehicle

A measurement method and technology of three-dimensional centroid, applied in the field of mechanical measurement, can solve the problems of complex mathematical model algorithm, complex disassembly process, influence of measurement accuracy, etc., and achieve the effect of simple moving and handling, simple calculation concept, and strong reference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The "horizontal and slope combined measurement method" of the present invention will be further described in conjunction with the accompanying drawings.

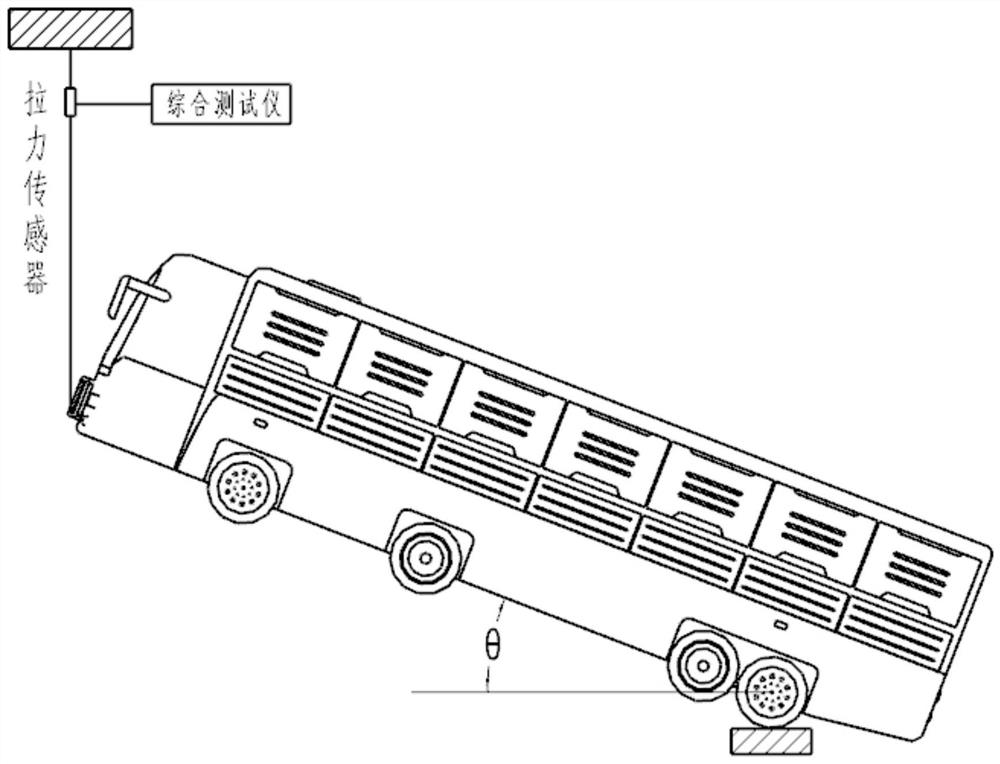

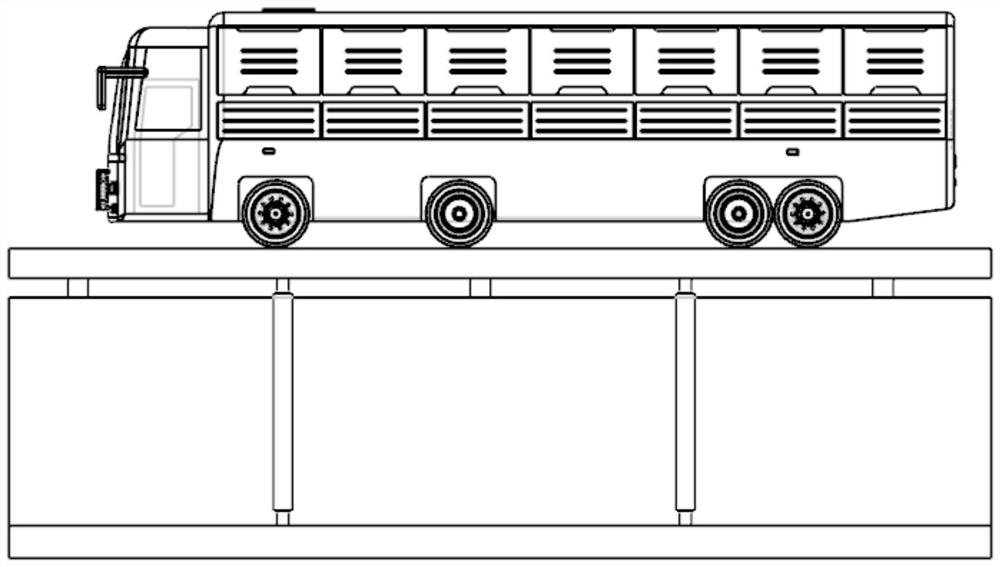

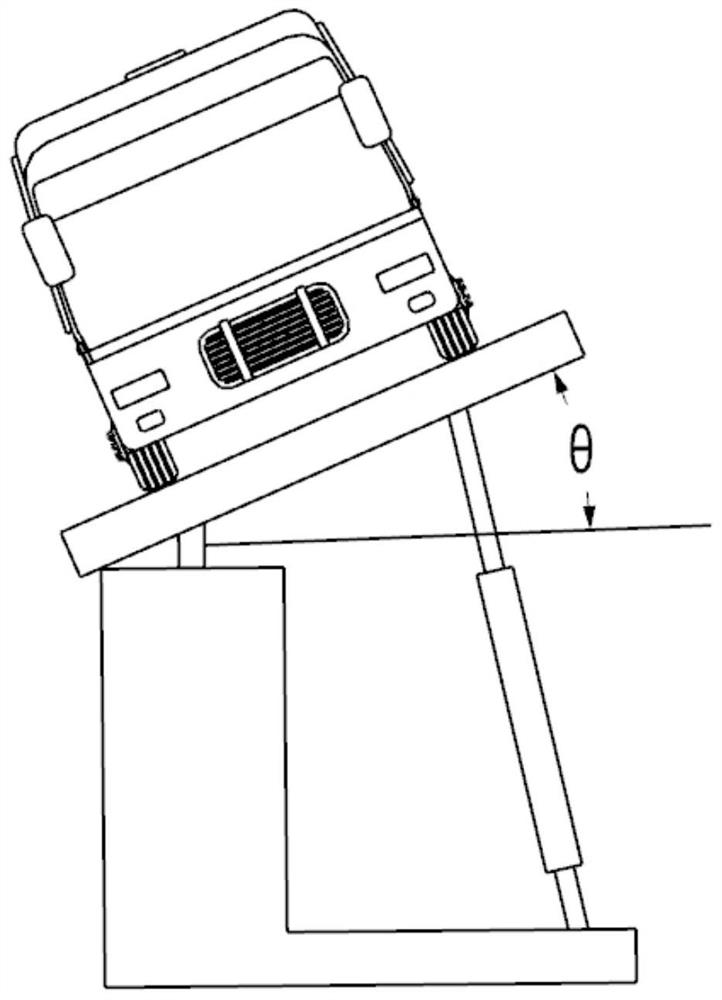

[0040] Taking a typical ultra-long and large vehicle with 4 axles and 8 wheels as an example, the following test methods can be referred to for implementation. Adopt 8 portable flat load cells fixedly installed on the horizontal ground / long slope according to the wheelbase and wheelbase, and drive to place directly under each wheel, and measure the centroid position in the X and Y directions with the horizontal method (such as image 3 As shown in ), use the "horizontal and slope combined measurement method" to measure the centroid position in the Z direction (such as Figure 4 shown in ). Such as Figure 5 Schematic diagram of the mathematical principle for measuring the center of mass of an ultra-long and large vehicle. The measurement and evaluation methods and steps are as follows:

[0041] 1. Measure the two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com