Positive electrode lead paste formula of lead-acid storage battery with long service life and preparation method of positive electrode lead paste formula

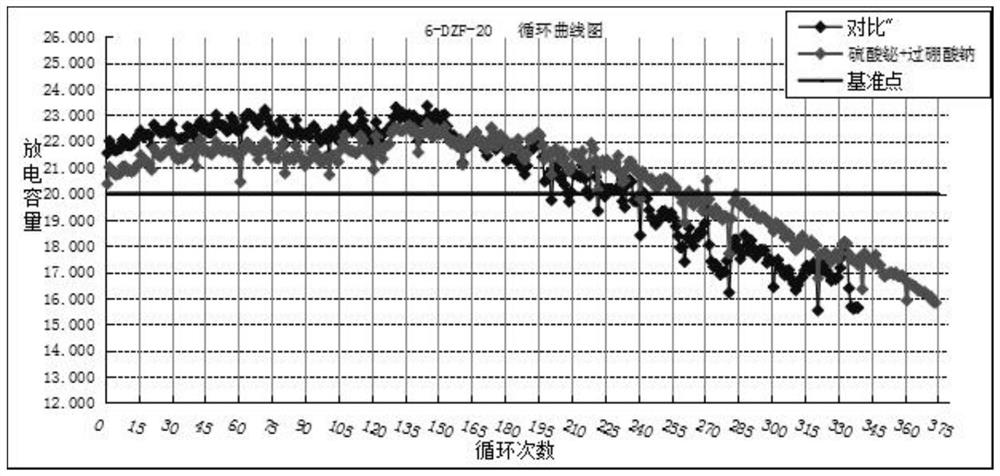

A lead-acid battery, positive lead paste technology, applied in lead-acid batteries, battery electrodes, circuits, etc., can solve the problems of active material shedding and poor binding force of active materials, and achieve the effect of enhancing binding force and improving cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A positive lead paste formula for a long-life lead-acid battery, characterized in that: according to the weight percentage of the components: lead powder 80%-85%, sulfuric acid 5%-10%, pure water 5%-10%, graphite 0.05% -0.2%, short fiber 0.05%-0.15%, bismuth sulfate 0.05%-2%, sodium perborate 0.05%-2%, the total weight percentage of each component is 100%.

[0021] The density of the sulfuric acid is 1.4g / cm 3 .

[0022] A preparation method for the positive electrode paste formula of long-life lead-acid storage battery, comprising the following steps:

[0023] S1. After adding 800kg of lead powder into the paste mixer, add 0.5kg of graphite, 0.5kg of short fiber, 0.5kg of bismuth sulfate and 0.5kg of sodium perborate configured in the above ratio, and perform dry stirring for 4 to 5 minutes;

[0024] S2. Add 50kg of pure water and add it into the paste mixer for wet stirring within 2 minutes, stirring for 4-6 minutes;

[0025] S3. After wet stirring, add 50 kg of su...

Embodiment 2

[0030] A positive lead paste formula for a long-life lead-acid battery, characterized in that: according to the weight percentage of the components: lead powder 80%-85%, sulfuric acid 5%-10%, pure water 5%-10%, graphite 0.05% -0.2%, short fiber 0.05%-0.15%, bismuth sulfate 0.05%-2%, sodium perborate 0.05%-2%, the total weight percentage of each component is 100%.

[0031] The density of the sulfuric acid is 1.4g / cm 3 .

[0032] A preparation method for the positive electrode paste formula of long-life lead-acid storage battery, comprising the following steps:

[0033] S1. After adding 850kg of lead powder into the paste mixer, add 2kg of graphite, 1.5kg of short fiber, 2kg of bismuth sulfate and 2kg of sodium perborate configured in the above ratio, and perform dry stirring for 4-5 minutes;

[0034] S2. Add 100kg of pure water into the paste mixer for wet stirring within 2 minutes, and stir for 4 to 6 minutes;

[0035] S3. After wet stirring, add 100kg of sulfuric acid into...

Embodiment 3

[0040] A positive lead paste formula for a long-life lead-acid battery, characterized in that: according to the weight percentage of the components: lead powder 80%-85%, sulfuric acid 5%-10%, pure water 5%-10%, graphite 0.05% -0.2%, short fiber 0.05%-0.15%, bismuth sulfate 0.05%-2%, sodium perborate 0.05%-2%, the total weight percentage of each component is 100%.

[0041] The density of the sulfuric acid is 1.4g / cm 3 .

[0042] A preparation method for the positive electrode paste formula of long-life lead-acid storage battery, comprising the following steps:

[0043] S1. After adding 825kg of lead powder into the paste mixer, add 1.25kg of graphite, 1kg of short fiber, 1.25kg of bismuth sulfate and 1.25kg of sodium perborate configured in the above ratio, and perform dry stirring for 4 to 5 minutes;

[0044] S2. Add 75kg of pure water and add it to the paste mixer for wet stirring within 2 minutes, and stir for 4-6 minutes;

[0045] S3. After wet stirring, add 75kg of sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com