Modularized rapidly-spliced photovoltaic module

A rapid splicing and photovoltaic module technology, applied in the direction of photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of high cost of replacement components, transportation and installation, large components, etc., and achieve simple structure, reduce transportation and installation costs, and ingenious design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

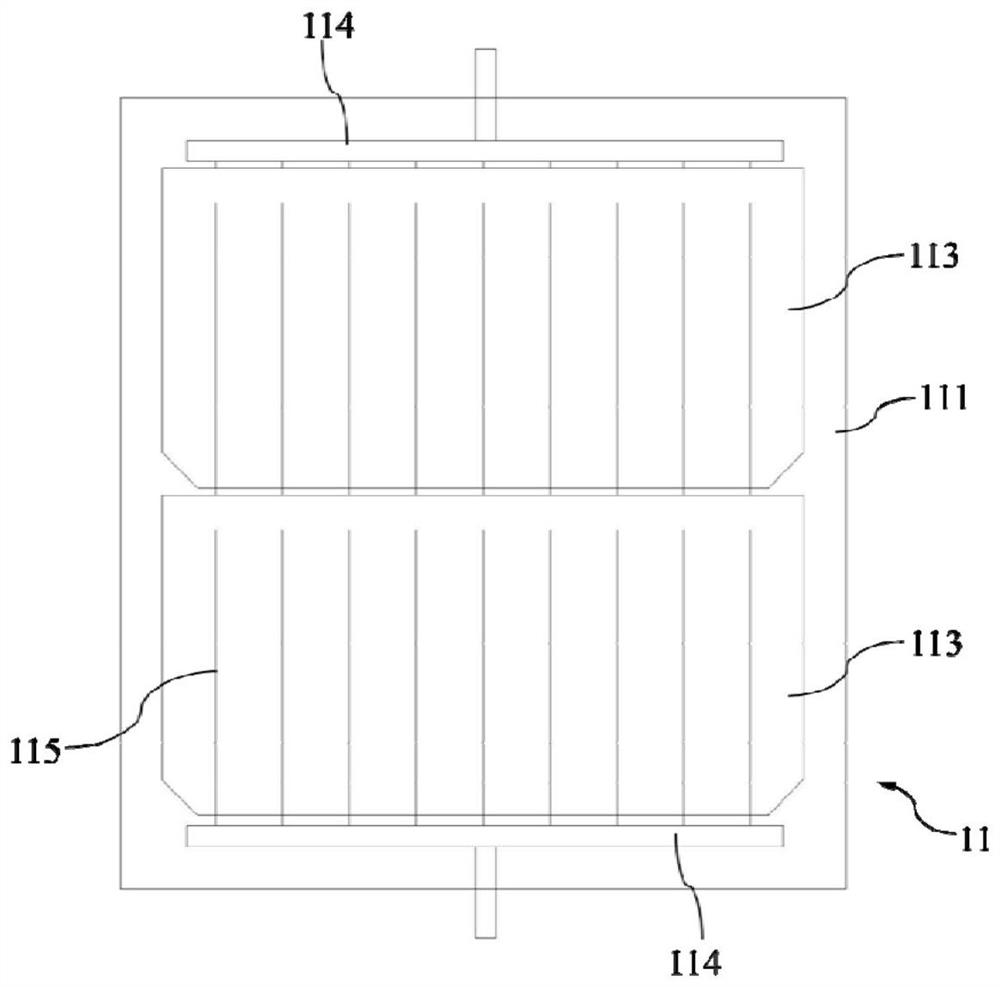

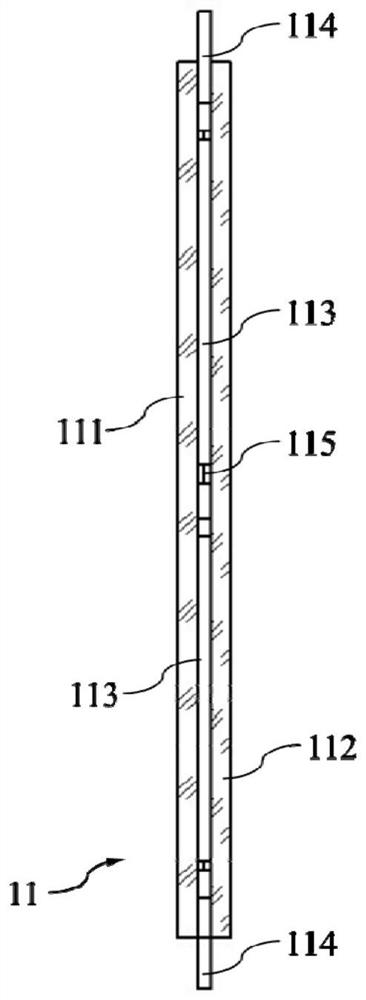

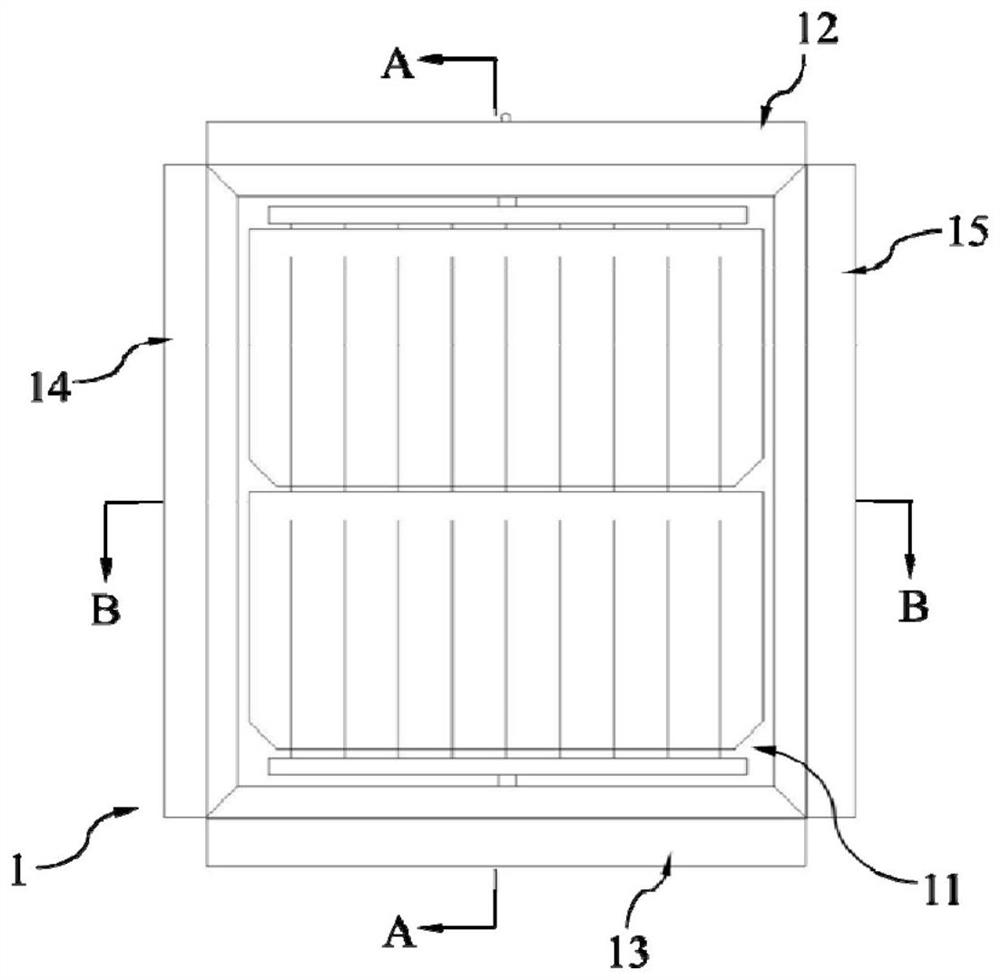

[0084] Such as Figure 18 , 19 As shown, in this embodiment, two module assemblies are connected in series, and the adjacent upper and lower frames are plugged in. After splicing, the left side of the two module assemblies is provided with a length equivalent to the length of the two module assemblies. Reinforcement, the right reinforcement of the same length is set on the right side, and the uppermost upper frame is plugged in as Figures 12 to 14 As shown in the positive connector, the lower frame at the bottom is plugged in as Figures 15-17 Negative connector shown.

Embodiment 2

[0086] Based on Example 1, such as Figure 20 As shown, this embodiment adopts four groups of module components, and adopts the connection mode of series connection and then parallel connection, that is, the upper and lower module components are first connected in series, and then the left and right sides are connected in parallel.

[0087] The structures of the positive connector and the negative connector used in this embodiment are as follows: Figures 21 to 24 As shown, since the assembly after splicing has two upper frames 12 and two lower frames 13 as a whole, the length dimensions of the positive connector and the negative connector, the size of the positive and negative protruding rings, and the dimensions of the positive and negative copper bottom plates The length and the number of negative electrode elastic parts and related components are set in accordance with the number of the upper frame 12 and the two lower frames 13 .

[0088] By analogy, after more module co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com