Evaporator, condenser and loop heat pipe

An evaporator and condenser technology, which is used in cooling/ventilation/heating renovation, indirect heat exchangers, lighting and heating equipment, etc., can solve the problem that heat pipe radiators and liquid cooling structures cannot meet the cooling needs of servers, and avoid The effect of heating up or even evaporating, improving the efficiency of heat efflux, and improving the efficiency of replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

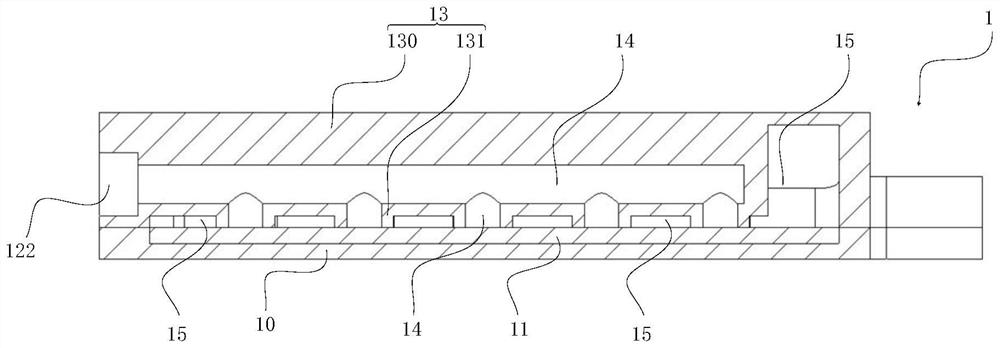

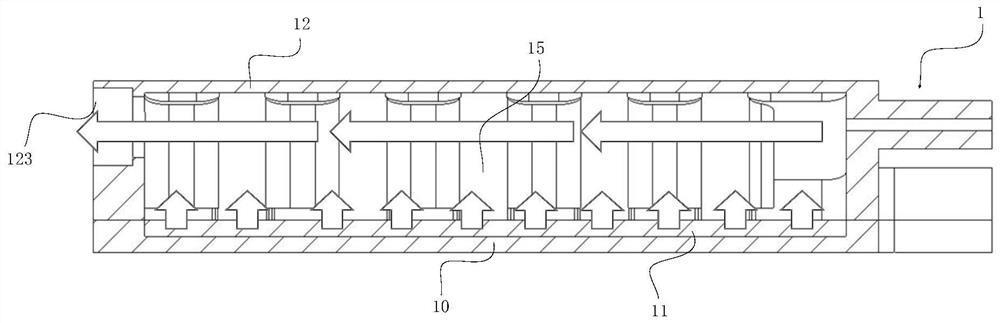

[0065] see figure 1 , figure 2 and see Figure 3 to Figure 11 As shown, the embodiment of the present application provides an evaporator 1 including a shell and a heat exchange evaporation layer 11 .

[0066] The inside of the housing is formed with a liquid replenishment chamber 14, an evaporation chamber 15 and an installation chamber. The housing is provided with a liquid inlet 122 communicating with the liquid replenishing chamber 14 and an air outlet 123 communicating with the evaporation chamber 15, wherein the heat transfer evaporation The layer 11 is arranged in the installation chamber, and the liquid replenishment chamber 14 and the evaporation chamber 15 are separated by the heat exchange evaporation layer 11 .

[0067] Among them, the evaporator 1 is used to be arranged on the heat source 4, and the temperature of the liquid working medium absorbs heat in the evaporator 1, and when the temperature reaches its boiling point, the phase changes into a high-temperat...

Embodiment 2

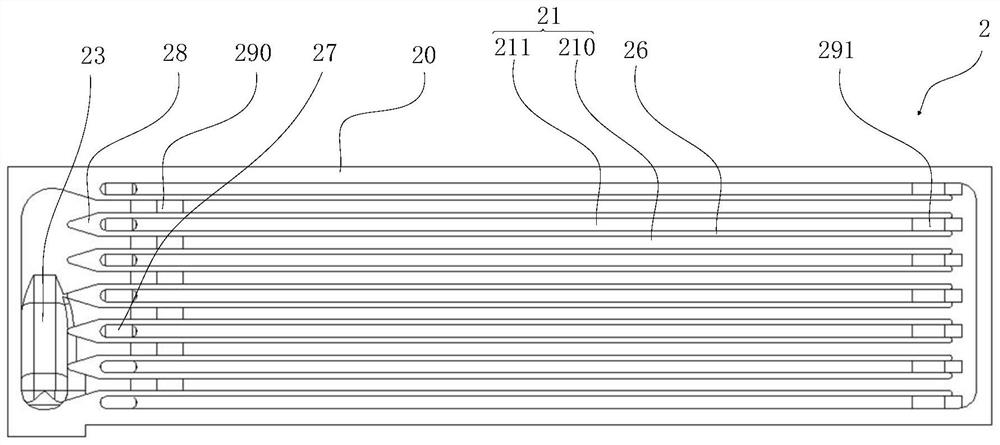

[0095] combine figure 1 , figure 2 , Figure 5 to Figure 11 and see image 3 and Figure 4 As shown, in the condenser 2 provided in this embodiment, a condensing chamber is formed inside the condensing body 20 , and the condensing body 20 is formed with a heat dissipation side wall 22 corresponding to the condensing chamber.

[0096] Optionally, the condensation body 20 includes a plate base 200 and a cover plate 201, the plate base 200 is provided with a groove, the cover plate 201 covers the groove, and the condensation cavity is formed by the groove.

[0097] The condensing body 20 is provided with an inlet passage 23 and an outlet passage 24, the inlet of the inlet passage 23 and the outlet of the outlet passage 24 penetrate the outer wall of the condensation body 20, and the outlet of the inlet passage 23 and the inlet of the outlet passage 24 are connected condensation cavity.

[0098] In order to enable the liquid working medium to flow out of the condensing body ...

Embodiment 3

[0111] Embodiment 3 provides a loop heat pipe 3, combined with Figure 1 to Figure 4 and see Figure 5 to Figure 11 As shown, this embodiment includes a radiator, the evaporator 1 in the first embodiment and the condenser 2 in the second embodiment, and the technical characteristics of the evaporator 1 disclosed in the first embodiment and the condenser 2 in the second embodiment are also Applicable to this embodiment, the technical features of the evaporator 1 disclosed in the first embodiment and the condenser 2 disclosed in the second embodiment will not be described repeatedly.

[0112] In the optional solution of this embodiment, the radiator is arranged on the heat dissipation side wall 22 of the condenser 2, so that the heat dissipation side wall 22 of the condenser 2 is cooled by the radiator, that is, the high temperature gas working medium inside the condenser 2 is cooled. Allow to cool.

[0113] Wherein, the radiator is an air-cooled radiator 30 or a liquid-cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com