Port deburring device for rail transit vehicle brake pipe joint production

A rail transit vehicle and deburring technology, which is applied in the field of port deburring devices, can solve problems such as low work efficiency, high labor intensity, and inconvenient clamping, so as to reduce manual labor intensity, realize end face deburring, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

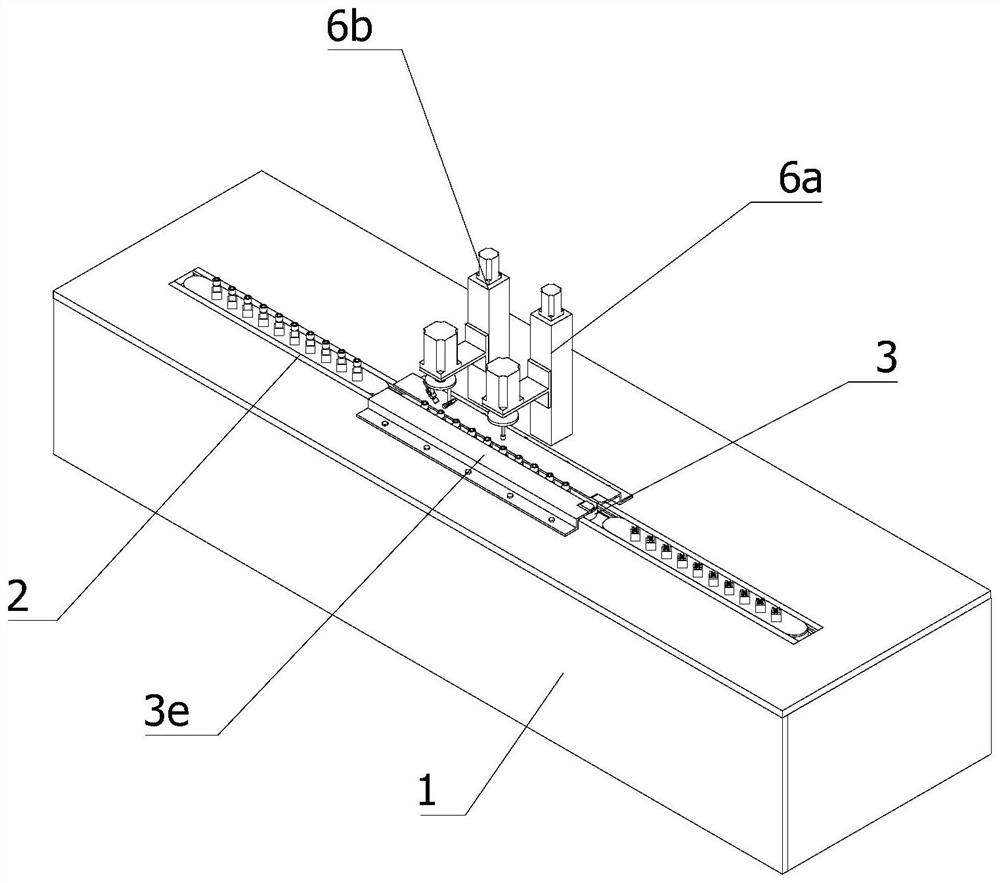

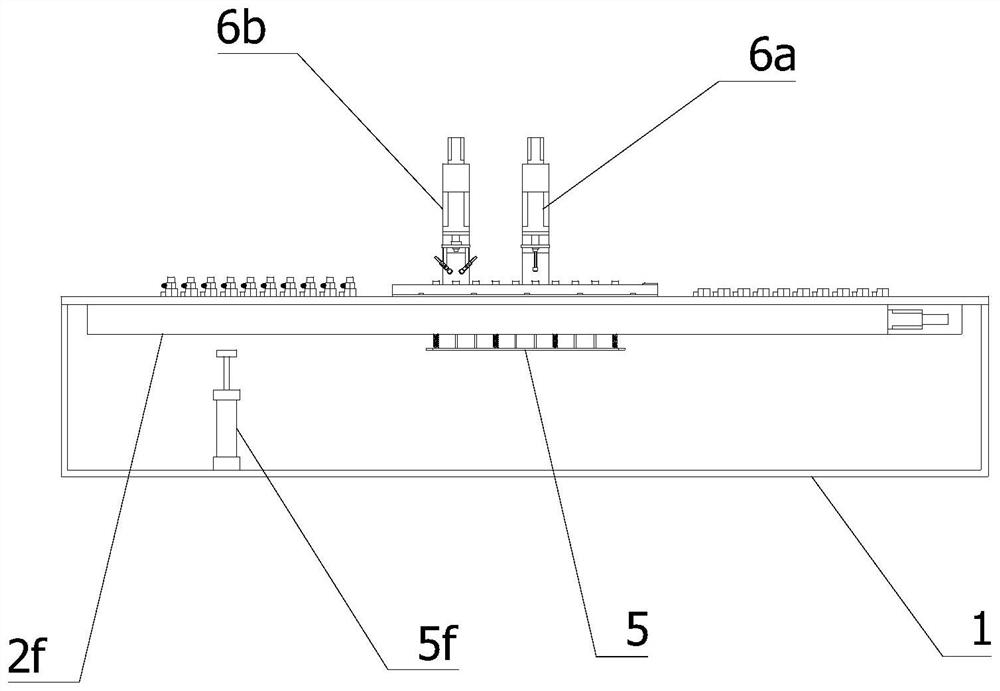

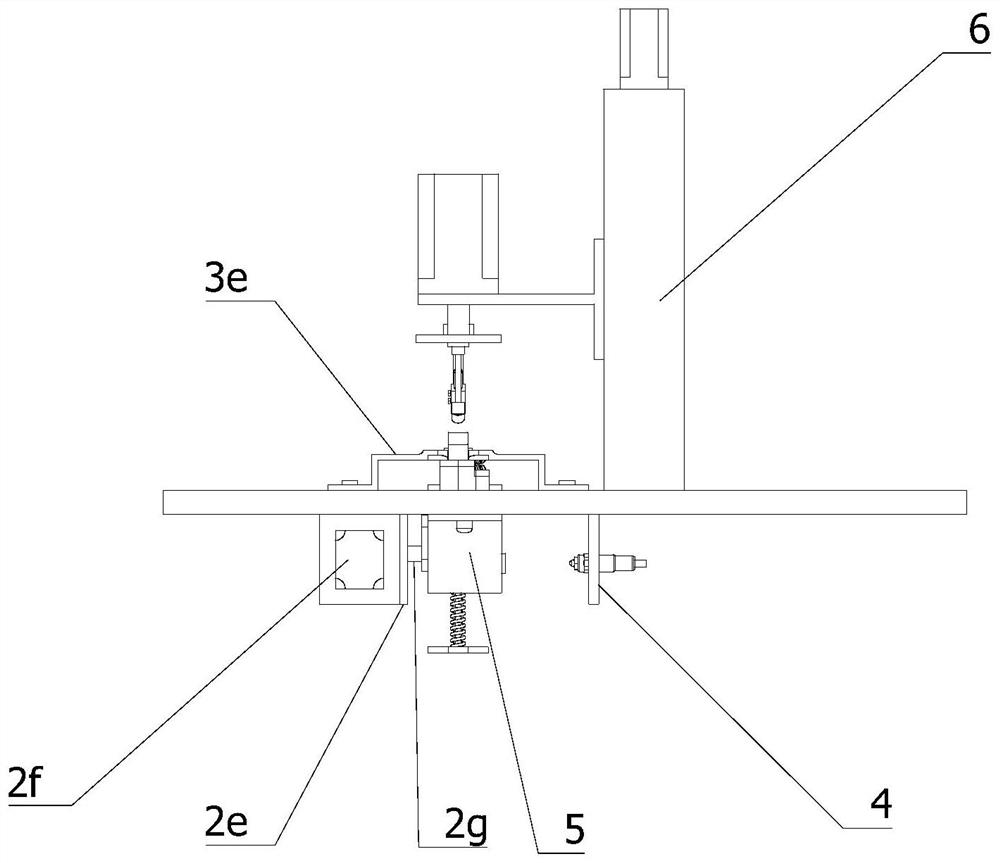

[0038] like Figure 1 to Figure 9 As shown, this application provides:

[0039]A port deburring device for the production of brake pipe joints of rail transit vehicles, comprising a frame 1, a linear reciprocating drive assembly 2, a material loading module 3, a sensing module 4, a material return assembly 5 and a deburring device 6; The reciprocating drive assembly 2 is horizontally embedded and installed on the upper surface of the frame 1 along the longitudinal direction of the frame 1; the loading module 3 is detachably arranged at the output end of the linear reciprocating drive assembly 2; at the bottom of the frame 1; the sensing module 4 is arranged in the middle of the linear reciprocating drive assembly 2; the material withdrawal assembly 5 is fixedly installed directly below the transmission end of the linear reciprocating drive assembly 2; the deburring device 6 is vertically arranged on the machine. The deburring device 6 is located on one side of the middle of t...

Embodiment 2

[0066] like Figure 7As shown, the second chamfering module 6b includes a third screw slide 6b1, a fifth connecting frame 6b2, a second servo motor 6b3, a second tool holder 6b4, an extension rod 6b5, a locking bolt 6b6 and a second chamfering knife 6b7; the fifth connecting frame 6b2 is fixedly installed on the output end of the third screw slide table 6b1; the second servo motor 6b3 is vertically arranged at the end of the fifth connecting frame 6b2; the output shaft of the second servo motor 6b3 passes through The second tool rest 6b4 is fixedly installed on the end of the output shaft of the second servo motor 6b3; the second tool rest 6b4 is coaxially arranged with the second servo motor 6b3 There are two extension rods 6b5, and the two extension rods 6b5 are in a mirror image state on both sides of the bottom of the second tool rest 6b4; the lower end of each extension rod 6b5 is also provided with an inclined slot; the second chamfering knife 6b7 can be The second cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com