Calibration Method of Laser Scanning Accuracy Controlled by Galvanometer

A technology of laser scanning and correction method, which is applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc. It can solve the problems of poor precision and long time-consuming laser scanning precision correction, and achieve the goal of reducing the difficulty of correction and eliminating the need for correction steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

[0035] The invention provides a laser scanning accuracy correction method controlled by a vibrating mirror. By introducing a similar printing technology, the equidistantness and collinearity of the feature points are guaranteed in advance, and then the laser spot is adjusted to align with the feature points, so that in a short time The position accuracy of the laser scanning plane can be calibrated within a few minutes, saving time and effort, and the accuracy is greatly improved.

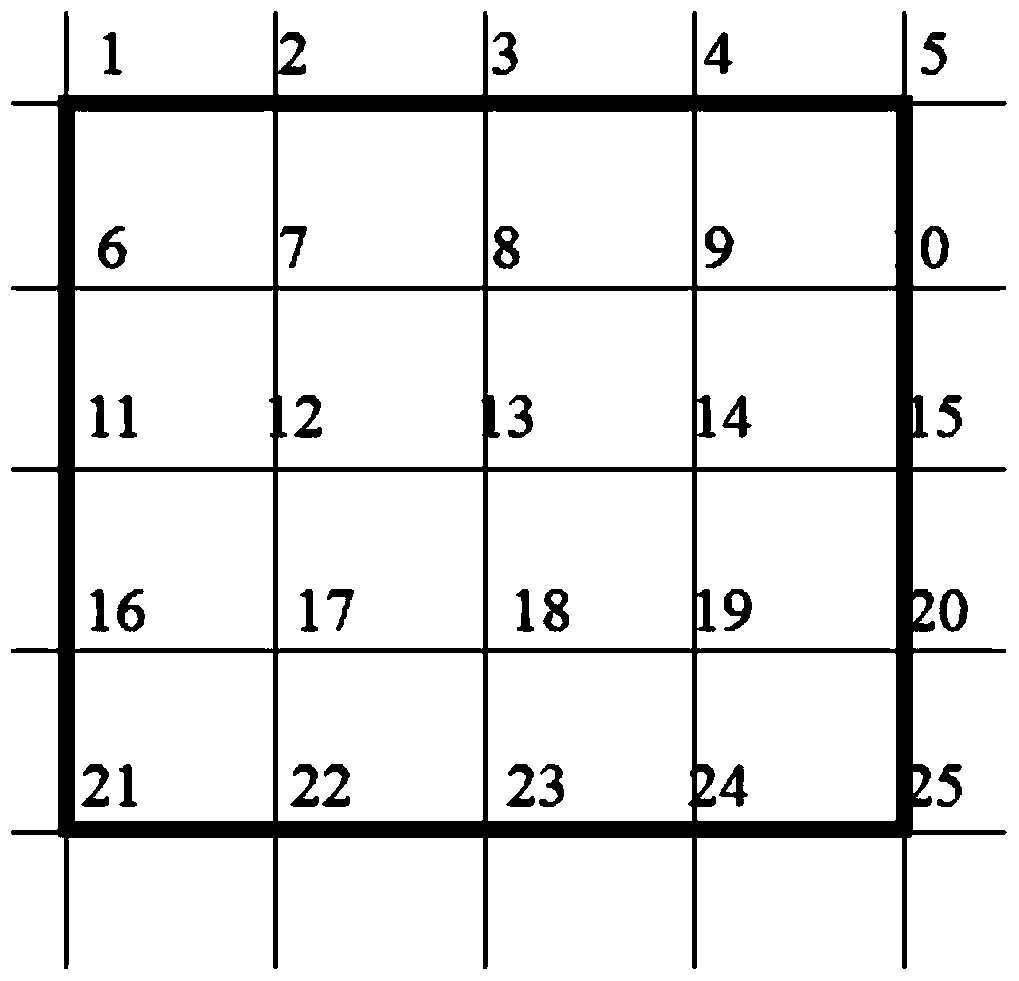

[0036] Specifically, such as Figure 4 As shown, the galvanometer control laser scanning accuracy correction method provided by the present invention includes the following steps:

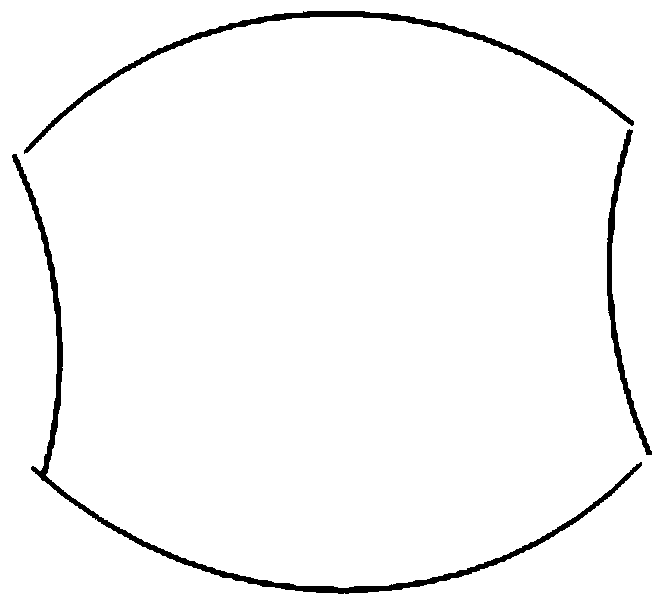

[0037] Step 1, when it is necessary to correct the scanning accuracy of the laser for a specific shape area, draw a square outside the specific shape area so that the specific shape area completely surrounds the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com