Wood fixed-length measurement cut-off control device and method for feller

A control device and length measurement technology, which is applied in the direction of measuring devices, feeding devices, wood processing equipment, etc., can solve the problems of poor cut-off length accuracy and inability to measure and adjust mechanical automation equipment, and achieve good versatility and simple and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

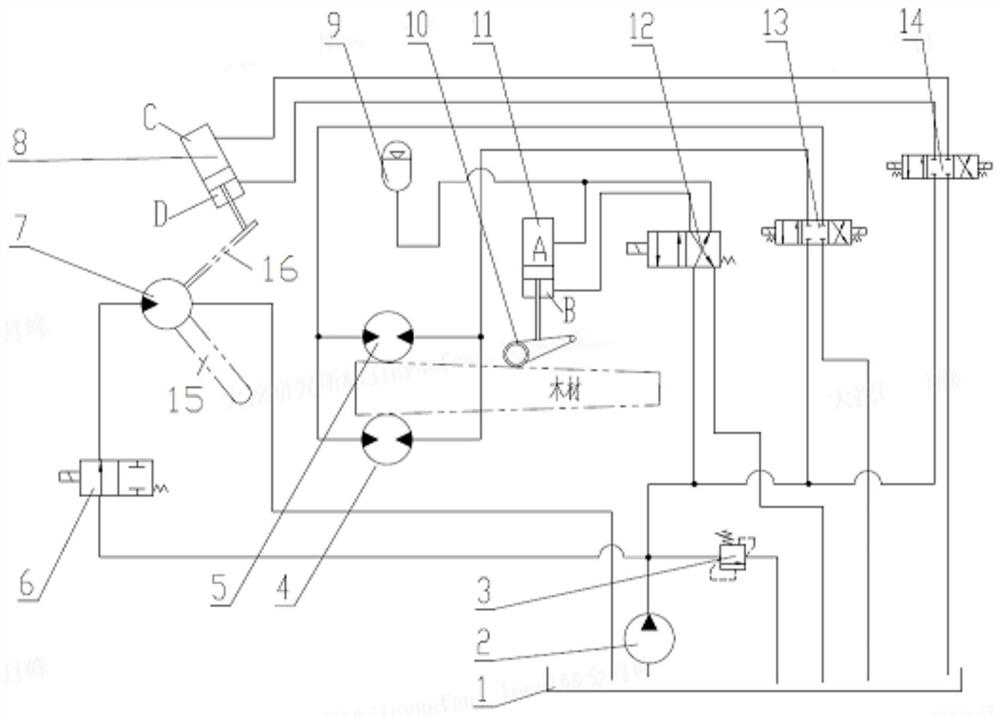

[0028] A timber cutting and measuring control device for logging equipment, the device mainly includes a hydraulic oil tank 1, a main pump 2, an overflow valve 3, a first feed motor 4, a second feed motor 5, a logging control valve 6, and a logging motor 7. Logging cylinder 8, accumulator 9, length sensor 10, length measuring cylinder 11, measurement control valve 12, feed control valve 13 and adjustment control valve 14, wherein the oil port on the lower side of the main pump 2 is connected to the hydraulic oil tank 1 , the upper oil outlet of the main pump 2 is connected with the left oil port of the overflow valve 3, the right oil port of the overflow valve 3 is connected with the hydraulic oil tank 1, the upper oil outlet of the main pump 2 is connected with the lower oil port of the logging control valve 6 The oil port on the upper side of the logging control valve 6 is connected with the left and right oil ports of the logging motor 7, the oil port on the right side of th...

Embodiment 2

[0032] A method for controlling lumber fixed-length measurement and truncation of a logging machine, comprising:

[0033] outputting a driving signal through a driving part;

[0034] Driving wood feeding through a feeding part based on a driving signal;

[0035] Feed length measurement during wood feeding through a length sensor;

[0036] The length sensor is connected to the piston rod of a length measuring oil cylinder, and the length sensor adjusts the oil pressure of the length measuring oil cylinder chamber through a fan generator to keep offset with the wood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com