Anode back plate for 3D printing

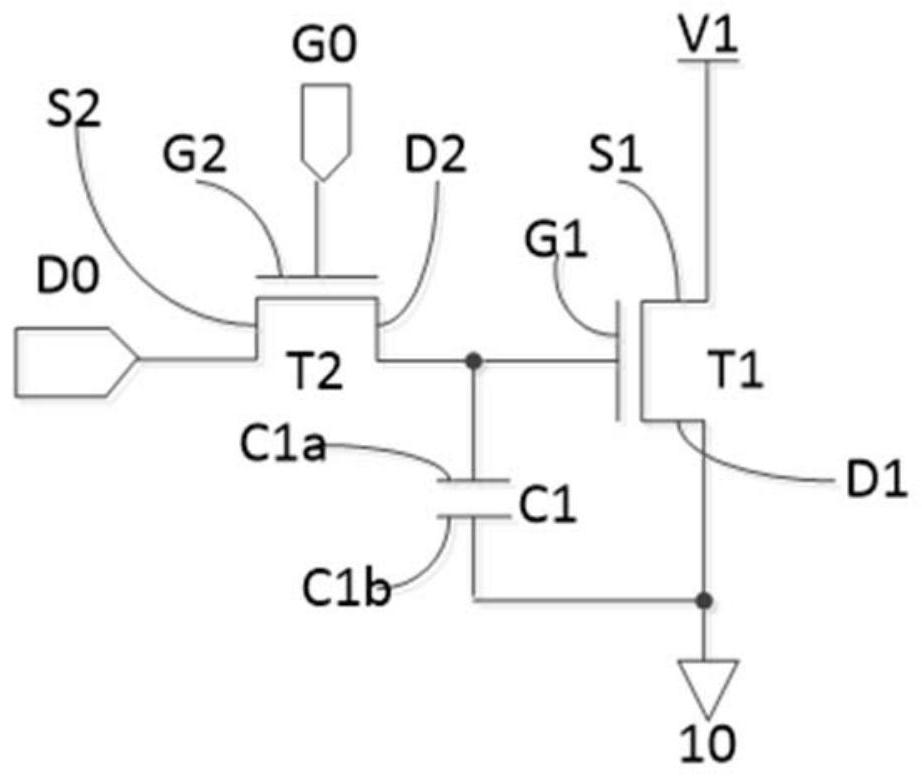

A 3D printing and anode technology, applied in the field of 3D printing, can solve the problems of inability to improve the aspect ratio of the driving transistor and the destruction of the active layer of the transistor, and achieve the effect of large aspect ratio, preventing damage and improving the driving ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

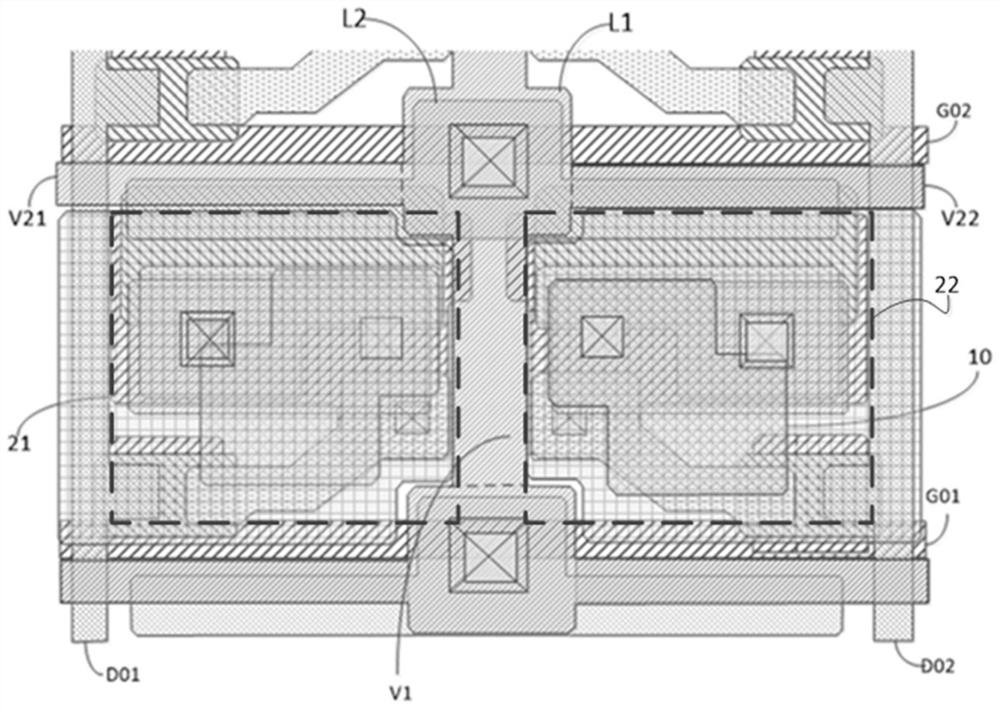

[0091] According to another specific implementation manner, the conductive patterns included in the conductive layer may be continuous with each other, and the orthographic projection of the conductive pattern on the base substrate covers the orthographic projection of the active layer pattern on the base substrate.

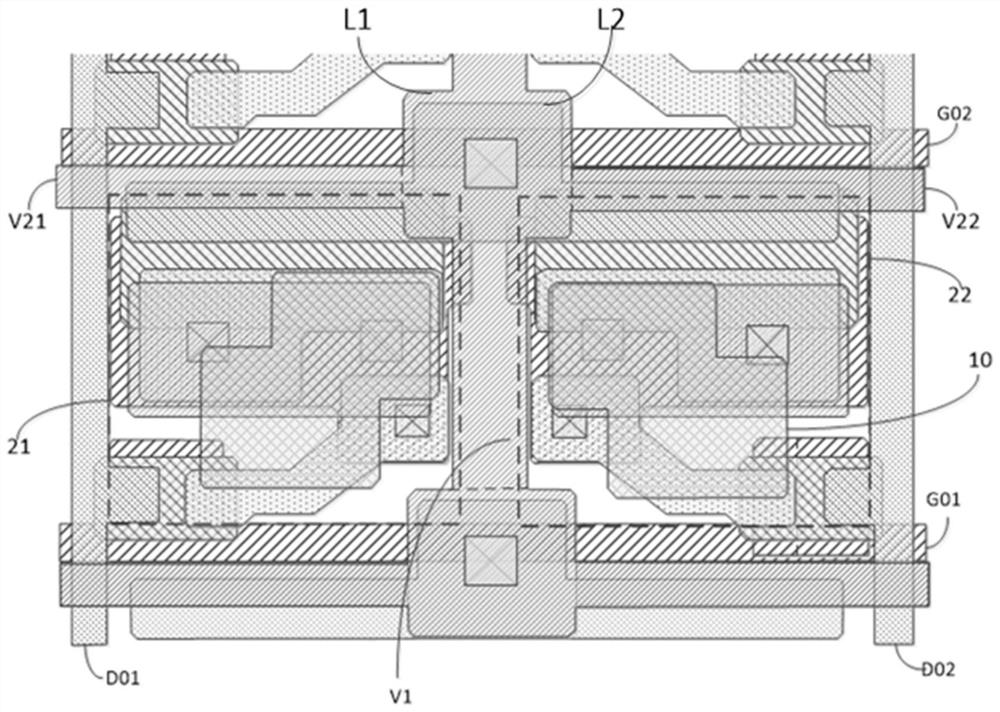

[0092] Such as figure 2 and Figure 4 As shown, the first gate line G01 has a first protrusion, the main body of the first gate line G01 extends along the row direction, the first protrusion protrudes from the main body of G01, and the gate G2 of the switching transistor is the first protrusion, so that the space occupied by the switching transistor is small;

[0093] Such as figure 2 and Figure 7 As shown, the first data line D01 has a second protrusion, the main body of the first data line D01 extends along the column direction, the second protrusion protrudes from the main body of D01, and the source S2 of the switching transistor is The second protrudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com