Rock physical parameter measurement system and method

A technology of parameter measurement and rock physics, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the constraints of test efficiency, data quality and big data application, low degree of information integration, artificial Problems such as too many readings, to achieve the effect of benefiting the application of big data, improving test efficiency, and improving data quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

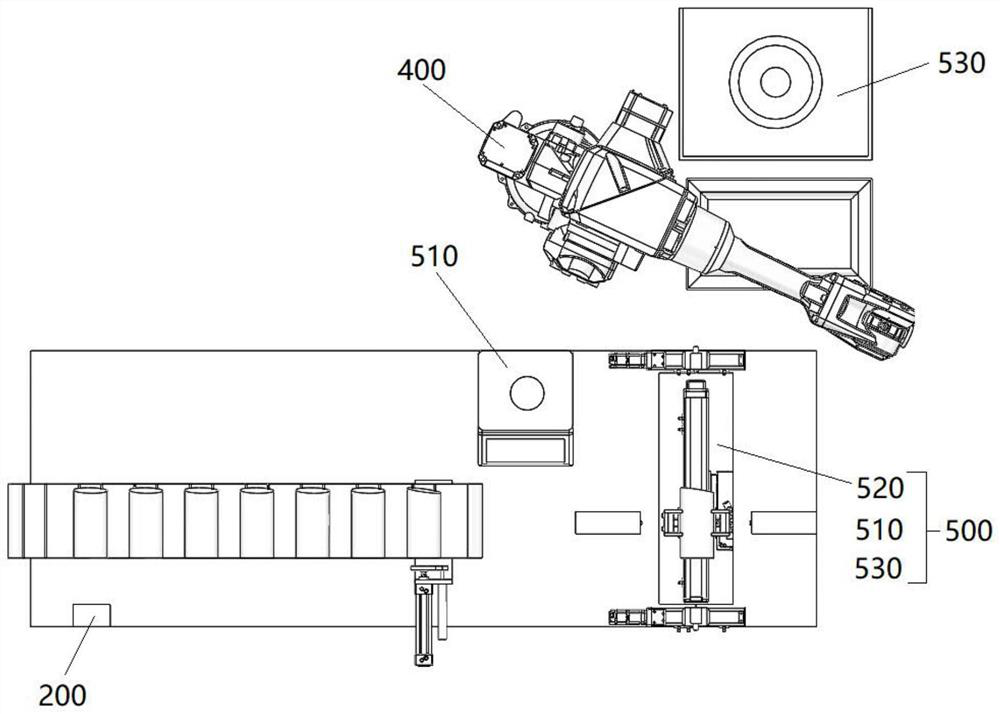

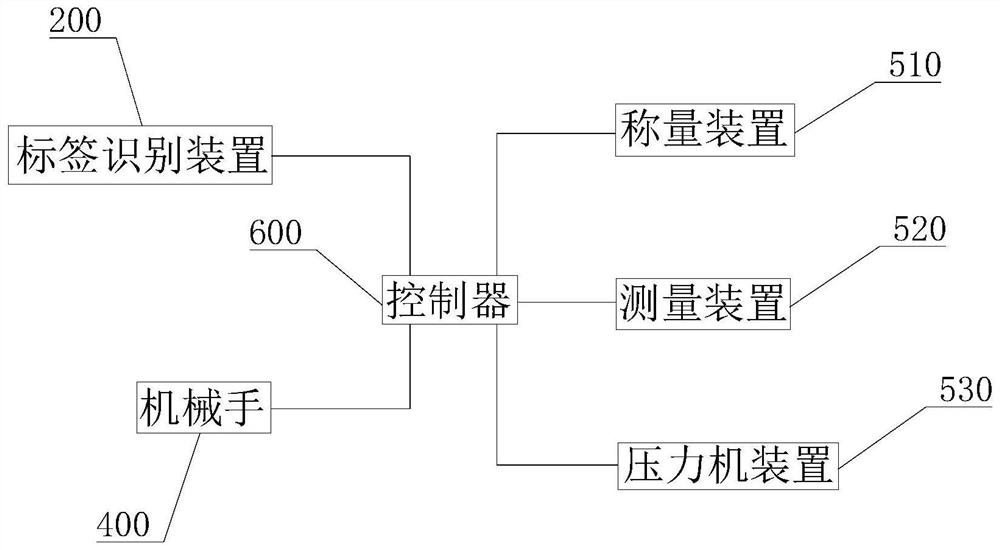

[0063] Please also refer to figure 1 and figure 2 , this embodiment provides a petrophysical parameter measurement system, which is applied in the petrophysical parameter detection process and can measure the bulk density and compressive strength of a rock sample. The petrophysical parameter measurement system includes a tag identification device 200 , a manipulator 400 , a physical parameter detection subsystem 500 and a controller 600 .

[0064] Wherein, the physical parameter detection subsystem 500 is composed of a weighing device 510 , a measuring device 520 and a press device 530 . The label identification device 200 , the manipulator 400 , the weighing device 510 , the measuring device 520 and the press device 530 are all electrically connected to the controller 600 .

[0065] When working, the tag identification device 200 identifies the tags set on the rock sample, collects the identity information of the rock sample and transmits it to the controller 600 . The co...

Embodiment 2

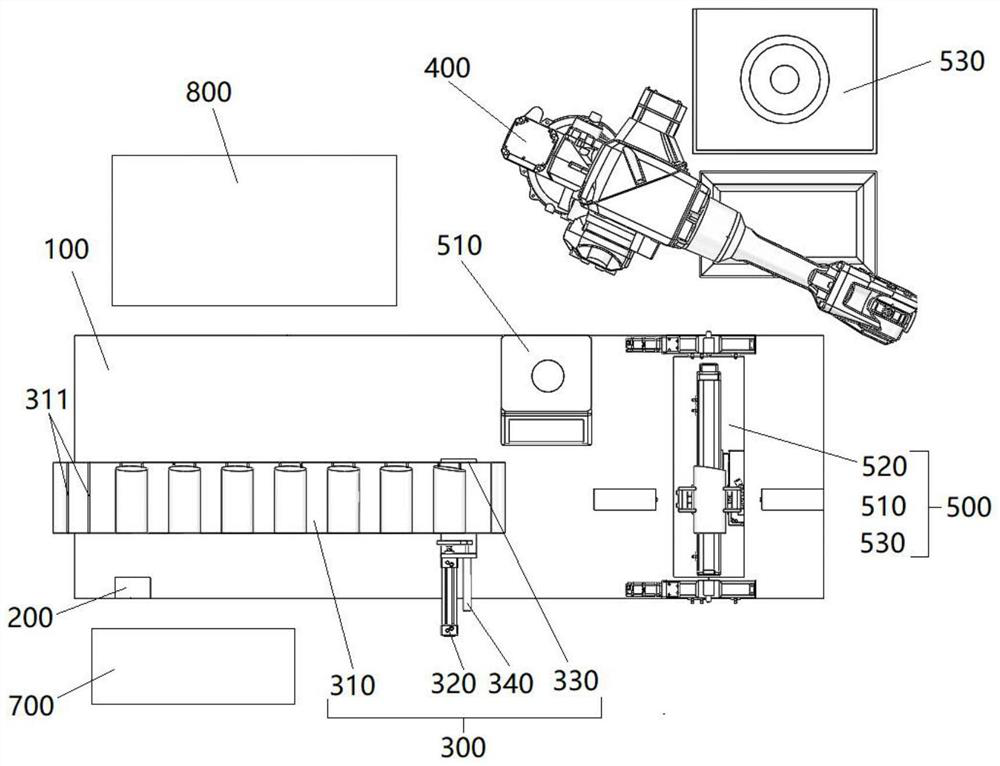

[0068] Please also refer to image 3 and Figure 4 , this embodiment provides a petrophysical parameter measurement system, which is applied in the petrophysical parameter detection process and can measure the bulk density and compressive strength of a rock sample. The petrophysical parameter measurement system includes a workbench 100 , a tag identification device 200 , a positioning and conveying device 300 , a manipulator 400 , a physical parameter detection subsystem 500 and a controller 600 . Wherein, the controller 600 is electrically connected with the manipulator 400, and controls the manipulator 400 to transfer the rock sample between the positioning conveying device 300 and the physical parameter detection subsystem 500, and completes the measurement of various physical parameters. The measurement results are further fed back to the controller 600, and the controller 600 calculates the bulk density and compressive strength of the rock sample.

[0069] Specifically,...

Embodiment 3

[0104] see Figure 7 , the present embodiment provides a petrophysical parameter measurement method, which is applied to the above-mentioned petrophysical parameter measurement system, comprising the following steps:

[0105] S1 , surveyors place the rock samples in the manual feeding area 700 on the feeding end of the conveyor belt 310 one by one.

[0106] S2, the tag identification device 200 identifies the tag on the rock sample, acquires the identity information of the rock sample, and transmits the identity information of the rock sample to the controller 600 .

[0107] S3, the controller 600 controls the manipulator 400 to transfer the rock sample to the weighing device 510 according to the identity information, and the weighing device 510 measures the quality of the rock sample and transmits the quality information of the rock sample to the controller 600 . Specific steps are as follows:

[0108] S3-1, the conveyor belt 310 transports the rock sample to the jacking cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com