Aerosol sorting and generating device

A technology for generating device and aerosol, which is used in measurement device, solid separation, permeability/surface area analysis, etc., can solve the problems of complex structure of sampler and inability to obtain particle size range, etc., to ensure smooth pipeline, uniform mixing, increase The effect of stacking space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

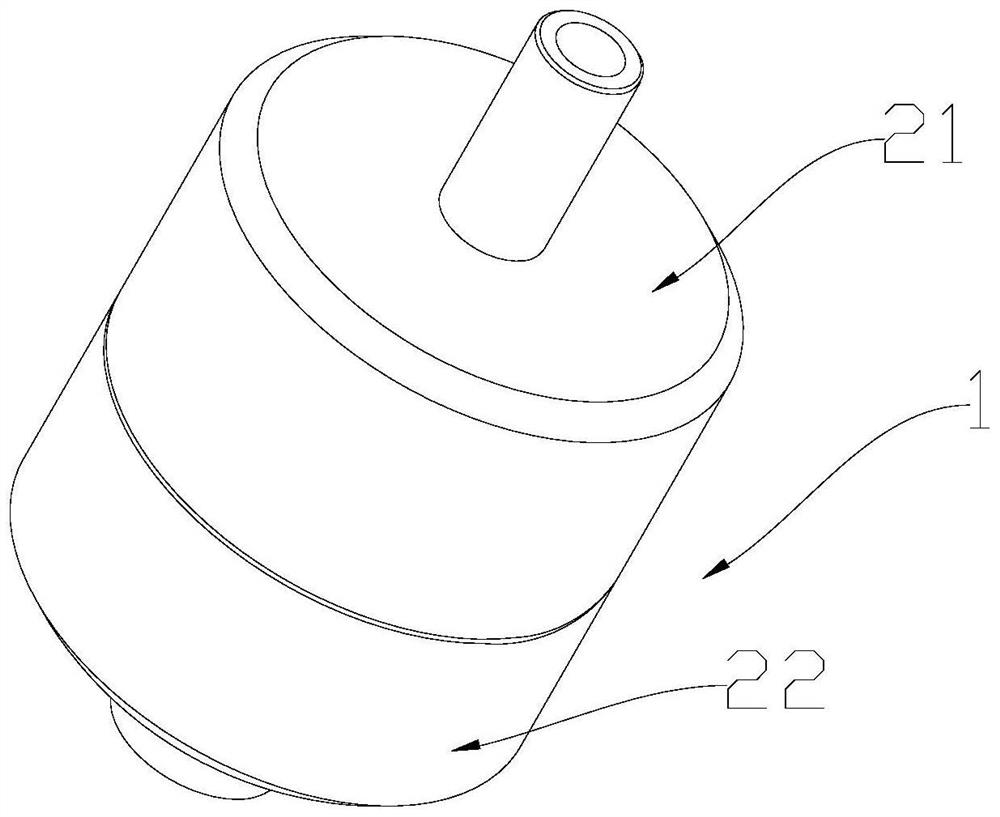

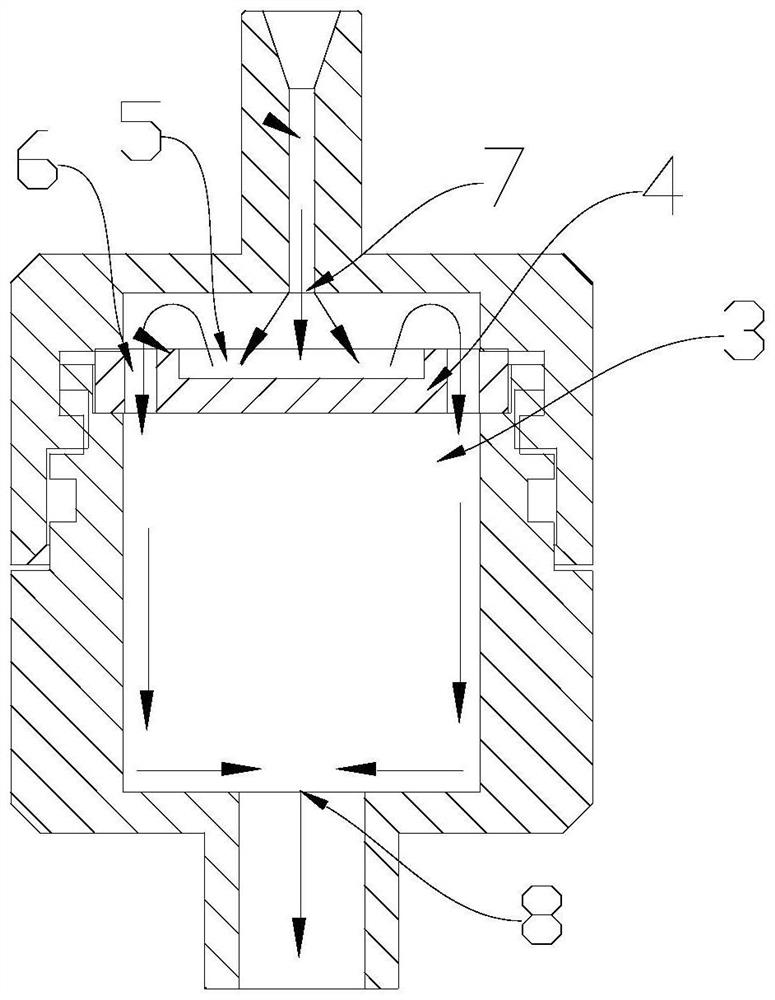

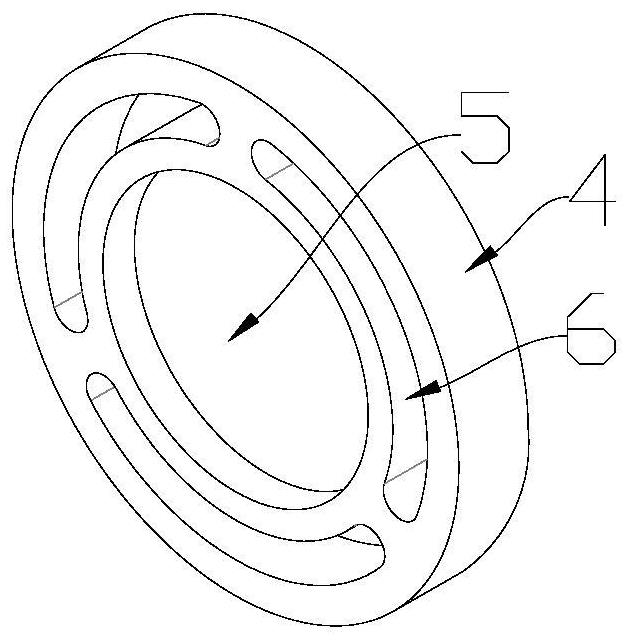

[0036] Such as Figure 1-3 As shown, this embodiment discloses an aerosol sorting generating device, including a collision filter 1, which includes a housing, and the structure of the housing is not specifically limited, and in this embodiment, it includes mutual sealing threaded connections The upper shell 21 and the lower shell 22, the housing cavity 3 is formed, the structure of the cavity 3 is various, in this embodiment, the cavity 3 is cylindrical, in the An impact plate 4 is installed in the placement cavity 3. The impact plate 4 has various shapes. In this embodiment, it is preferably a cylinder or a circular plate. The edge of the impact plate 4 is in contact with the side wall of the placement cavity 3. Or the inner wall of the housing fits or fits, specifically, the edge of the impact plate 4 fits between the upper housing 21 and the lower housing 22, and is formed by the upper housing 21 and the lower housing. The body 22 is extruded and fixed; the material of the...

Embodiment 2

[0038] Such as Figure 4 As shown, this embodiment discloses an aerosol sorting generating device, which is a modification based on Embodiment 1, and the specific difference is as follows: the air outlet 7 extends toward the impact plate 4 to form a tube body 8 , the backflow groove 9 is formed between the outer wall of the pipe body 8 and the side wall of the placement cavity 3 or the inner wall of the housing, the backflow groove 9 is preferably circular, and the depth of the backflow groove 9 is between 5- 10mm.

Embodiment 3

[0040] Such as Figure 5 As shown, this embodiment discloses an aerosol sorting generating device, which is a modification based on Embodiment 1 or 2, and the specific differences are as follows: it also includes an air inlet pipe 11 and an air outlet pipe 12; multiple collision filters 1 is connected in parallel with the outlet pipe 12 through the air inlet pipe 11; the airflow inlet 7 of each collision filter 1 is respectively communicated with the air inlet pipe 11; the airflow outlet of each collision filter 1 8 communicate with the outlet pipes 11 respectively. In this implementation, the collision filter 1 can be of the same specification or of different specifications, and the different specifications mainly refer to the diameter of the airflow inlet 7 and the distance between the airflow inlet 7 and the impact plate 4 (impact groove 5) Collision filters 1 for intercepting particles with different particle sizes are realized by different methods.

[0041] Further, for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com