Splitting machine sampling device for gravure production line

A slitting machine and production line technology, applied in the printing field, can solve problems such as eardrum damage, and achieve the effect of ensuring efficiency, easy search and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

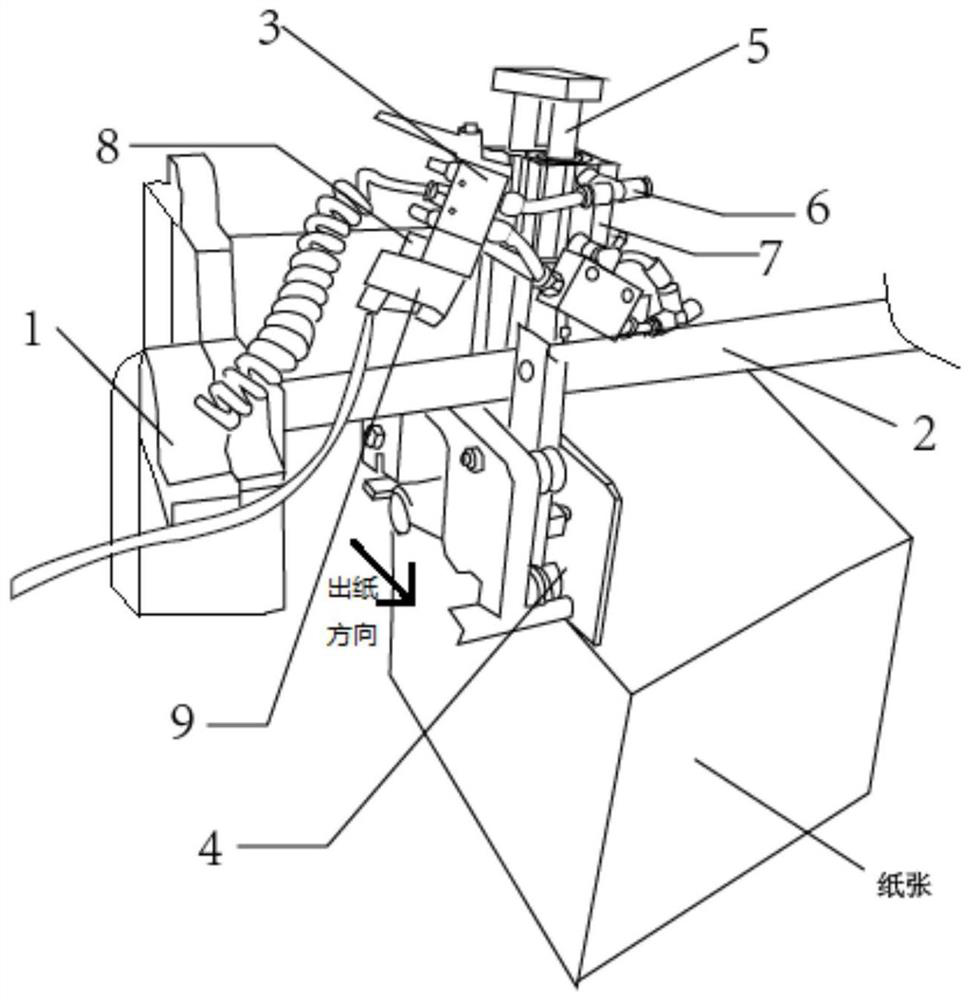

[0032] see Figure 1-8, in the embodiment of the present invention, a kind of slitter sampling device used in gravure printing production line, comprises the slitter 1 that is used for slitting paper 12, and the output end of slitter 1 is provided with receiving table 10, and receiving table A weighing device is installed in the 10, a conveyor belt 11 is arranged on the top of the receiving platform 10, the upper surface of the conveyor belt 11 is used to accept the paper 12, and a base 7 is arranged above one end of the conveyor belt 11 outputting the paper 12, and a The electronic valve 3, the output end of the electronic valve 3 is connected with the gas rod 5, the gas rod 5 is connected with the baffle 4, the gas rod 5 drives the baffle 4 to move up and down; A power interface 9 is provided, and a switch 8 is provided on the power interface 9;

[0033] When the baffle 4 goes down to the maximum stroke, the movement of the paper 12 is blocked and used for the stacking of t...

Embodiment 2

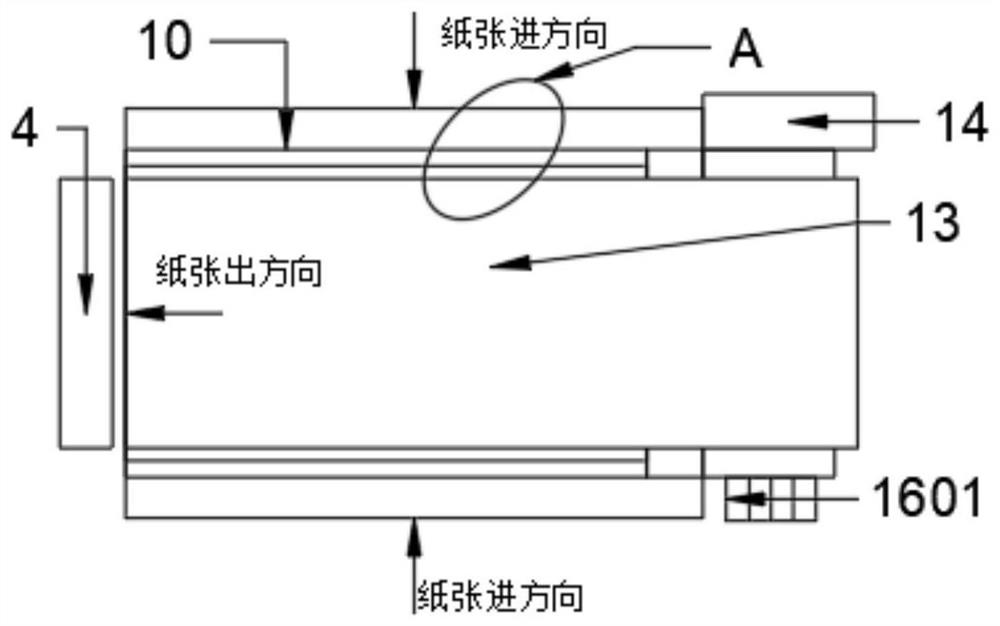

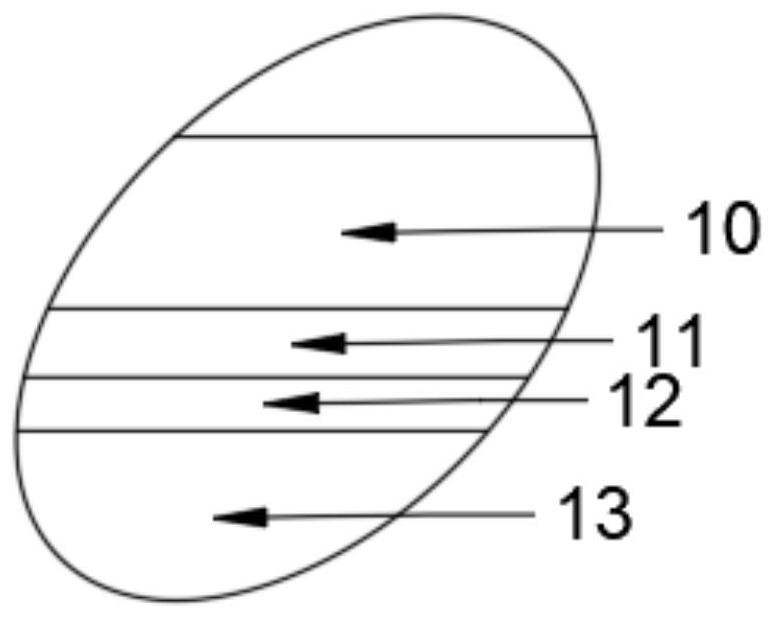

[0035] This embodiment is further improved on the basis of Embodiment 1. This embodiment is a specific implementation of the upper structure of the conveyor belt 11 in Embodiment 1 that accepts the paper stack: a mounting plate 14 is provided above the conveyor belt 11, and the installation A first rotating shaft 15 and a second rotating shaft 16 are installed on the plate 14, an irregular gear 1501 is installed on the outer wall of the first rotating shaft 15, and a rotating gear 1601, an irregular gear 1501 and a rotating gear are installed on the outer wall of the second rotating shaft 16. 1601 meshing, the outer wall of the second rotating shaft 16 is connected with a pressing plate 13, the second rotating shaft 16 drives the pressing plate 13 to rotate, the lower surface of the pressing plate 13 is equipped with a paper stack labeling machine 31a, and the mounting plate 14 is equipped with a fixed block 17, the pressing plate 13 A first elastic member 18a is installed betw...

Embodiment 3

[0038] This embodiment is further improved on the basis of Embodiment 2. This embodiment is a specific implementation of the upper structure of the pressing plate 13 in Embodiment 2: a frame 21 is installed on the upper surface of the pressing plate 13, and a frame 21 is installed on the frame 21. Conveyor belt 22, the outer wall edge of conveyor belt 22 is equipped with mounting block 23, is installed on the mounting block 23 with the sleeve 24 that is perpendicular to the moving direction of conveyor belt 22, is nested with fixed rod 25 that rotates in sleeve 24, and fixed rod 25 is fixedly connected with Connecting plate 26, connecting plate 26 is provided with strip-shaped hole, is nested with connecting rod 27 in the strip-shaped hole, and connecting rod 27 slides in the strip-shaped hole, and connecting rod 27 lower end is fixedly connected with slide plate 20, and slide plate 20 is used for undertaking the first A sheet of paper 12, the first sheet of paper 12 is defined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com