Marine container air conditioner

A container ship and air-conditioning technology, applied in ship construction, ship parts, transportation and packaging, etc., can solve the problems of energy waste, power consumption, high operating costs, etc., and achieve the effect of saving power consumption and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

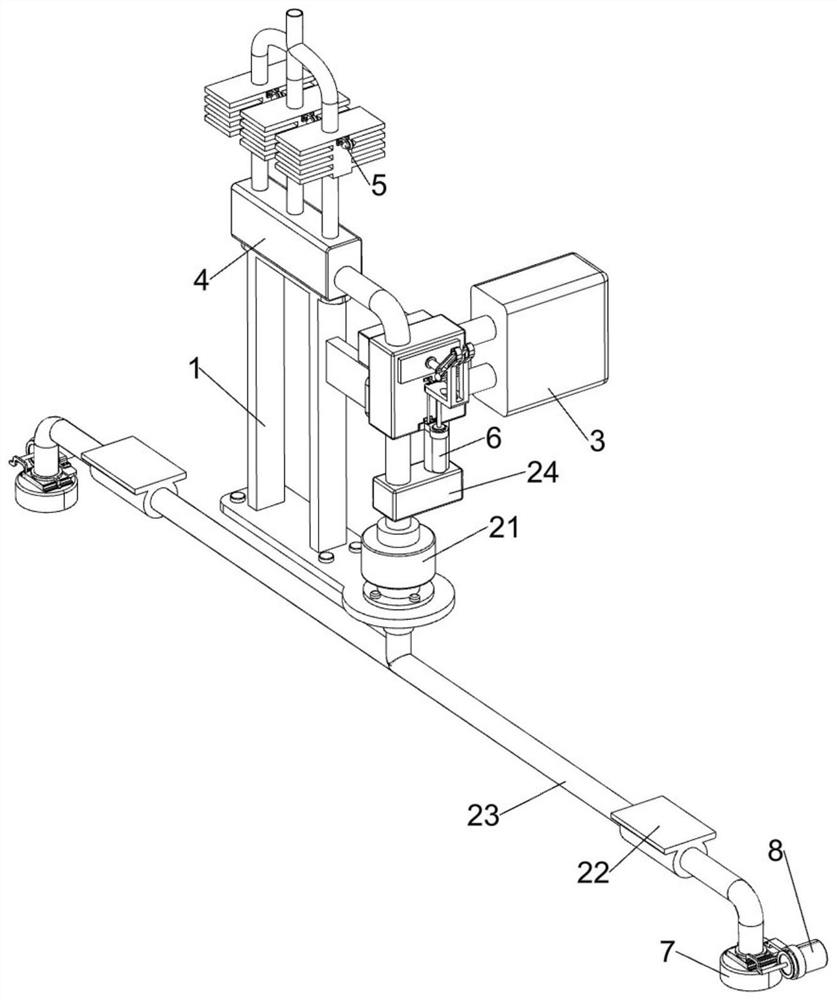

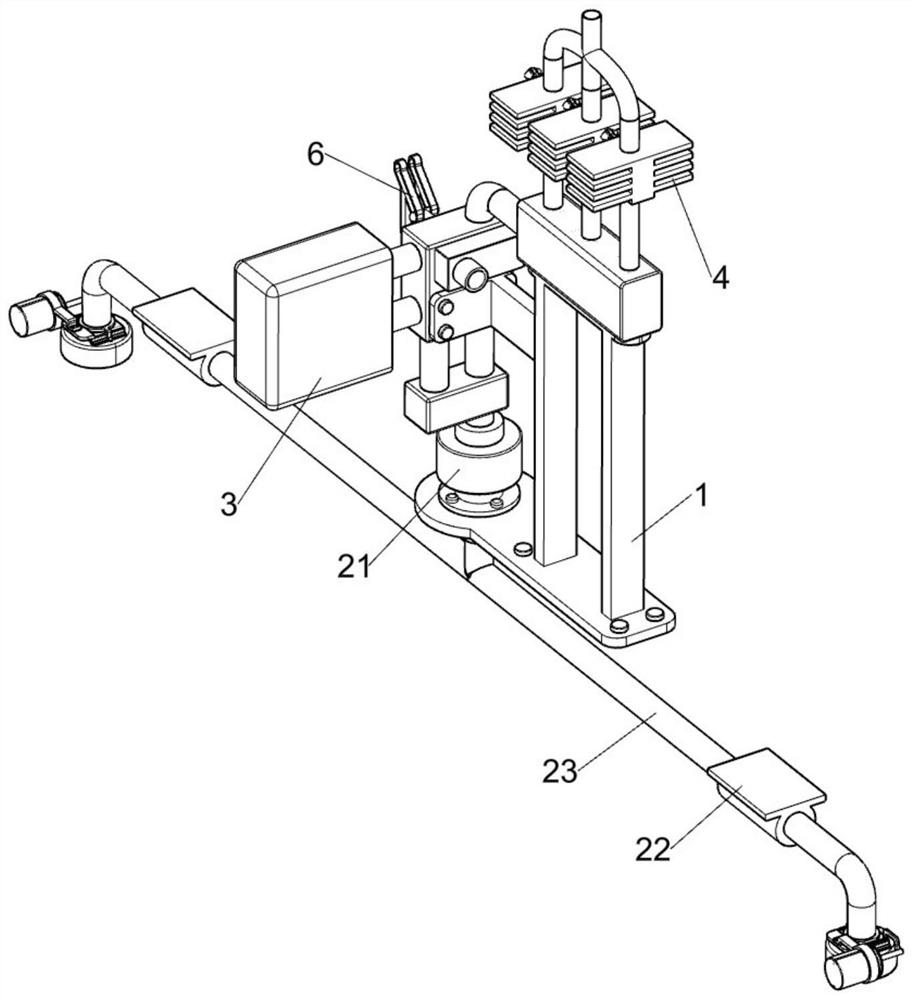

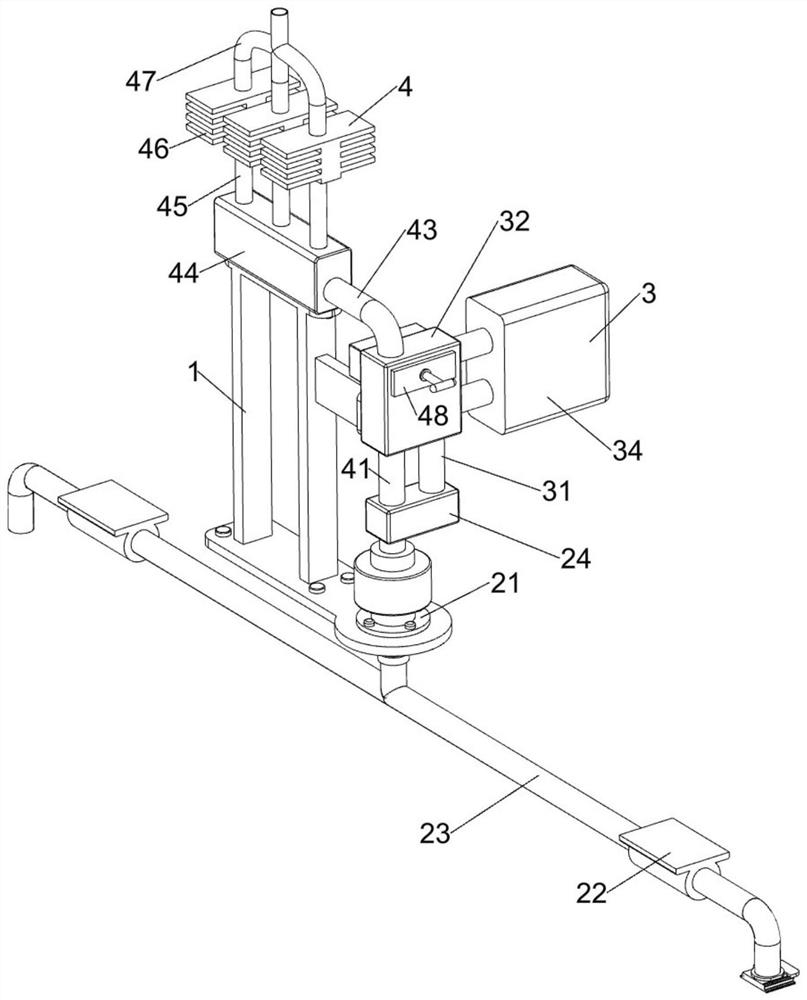

[0043] Ocean container marine air conditioner, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, it includes a fixed installation frame 1, a water pump 21, a perforated support frame 22, a T-shaped water suction pipe 23, a shunt pipe 24, a fuel-fired power generation room cooling assembly 3 and an air temperature adjustment assembly 4, and the top of the fixed installation frame 1 is fixed with Suction pump 21. Suction pump 21 is used to pump constant temperature seawater upwards. A pair of perforated support frames 22 are fixedly connected to the bottom of the hull. A T-shaped water suction pipe 23 is fixedly connected between the two perforated support frames 22. The T-shaped water suction pipe 23 is used to transport constant temperature seawater, T-shaped water pipe 23 passes through the fixed mounting frame 1, T-shaped water pipe 23 is connected with the bottom of the water pump 21, and a shunt pipe 24 is connected above the water...

Embodiment 2

[0050] On the basis of Example 1, such as Figure 7 As shown, it also includes a temperature-sensing adjustment assembly 5. The temperature-sensing adjustment assembly 5 is arranged on the shunt cavity 44. The temperature-sensing adjustment assembly 5 is used to sense the temperature in each compartment of the cabin in real time. The temperature-sensing adjustment assembly 5 includes an electromagnetic The valve 51 and the temperature sensor 52 are fixed with three electromagnetic valves 51 in a linear distribution manner in the top of the diversion cavity 44. The electromagnetic valves 51 are used to control the circulation of seawater in the diversion tube 45. The adjacent electromagnetic valves 51 and the guide tube The flow pipe 45 is fixedly connected, and the right side of the temperature regulator 46 is fixedly connected with a temperature sensor 52, and the temperature sensor 52 is used to sense the temperature in the cabin compartment to control the switch of each elec...

Embodiment 3

[0053] On the basis of Example 2, such as Figure 8 As shown, it also includes a switching assembly 6, which is arranged on the right side outside the support block 32, and the switching assembly 6 is used to automatically switch the heating and cooling. The switching assembly 6 includes a T-shaped opening frame 61, an electric push rod 62 , slide rail frame 63 and slotted limit frame 64, the outside right side of the support block 32 is fixedly connected with a T-shaped hole frame 61, and the T-shaped hole frame 61 is fixedly equipped with an electric push rod 62, and the outside right side of the support block 32 Affixed with slide rail frame 63, one end of electric push rod 62 telescopic shafts is affixed with slotted limit frame 64, and slotted limit frame 64 top has a pair of oblique chute (in Figure 8 shown in ), the slotted limit frame 64 is used to pull out or push in the T-shaped push rod 410, instead of manually pulling out or pushing in the T-shaped push rod 410, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com