Power transmission line inspection robot

A technology for inspection robots and power lines, applied in the field of automation, can solve problems such as inability to meet actual use requirements, short detection distance, danger, etc., and achieve the effects of improving peer efficiency, simple and convenient use, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

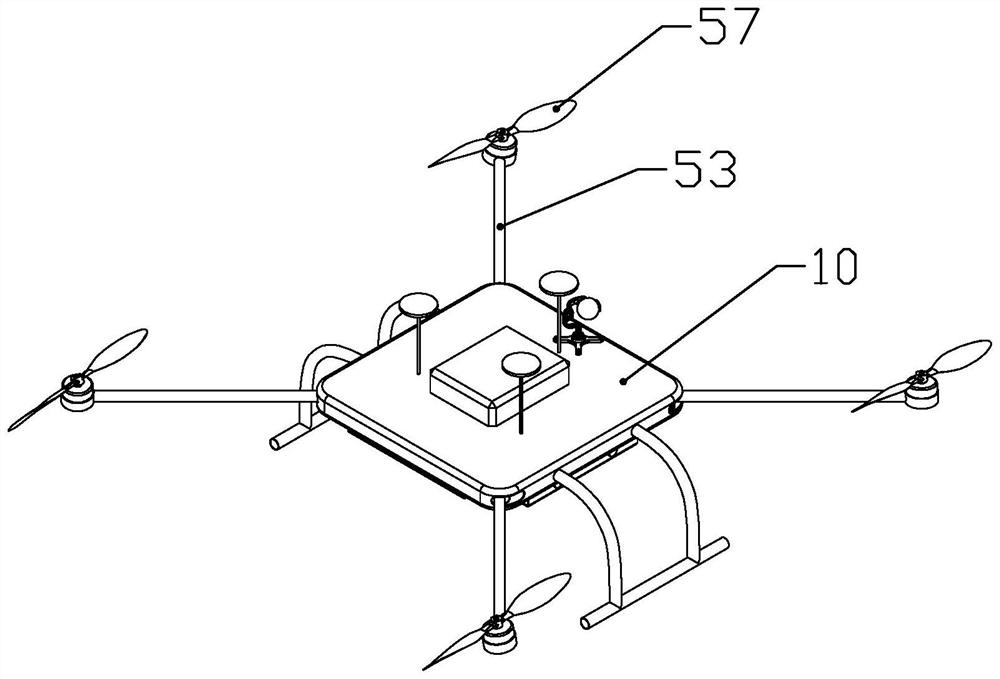

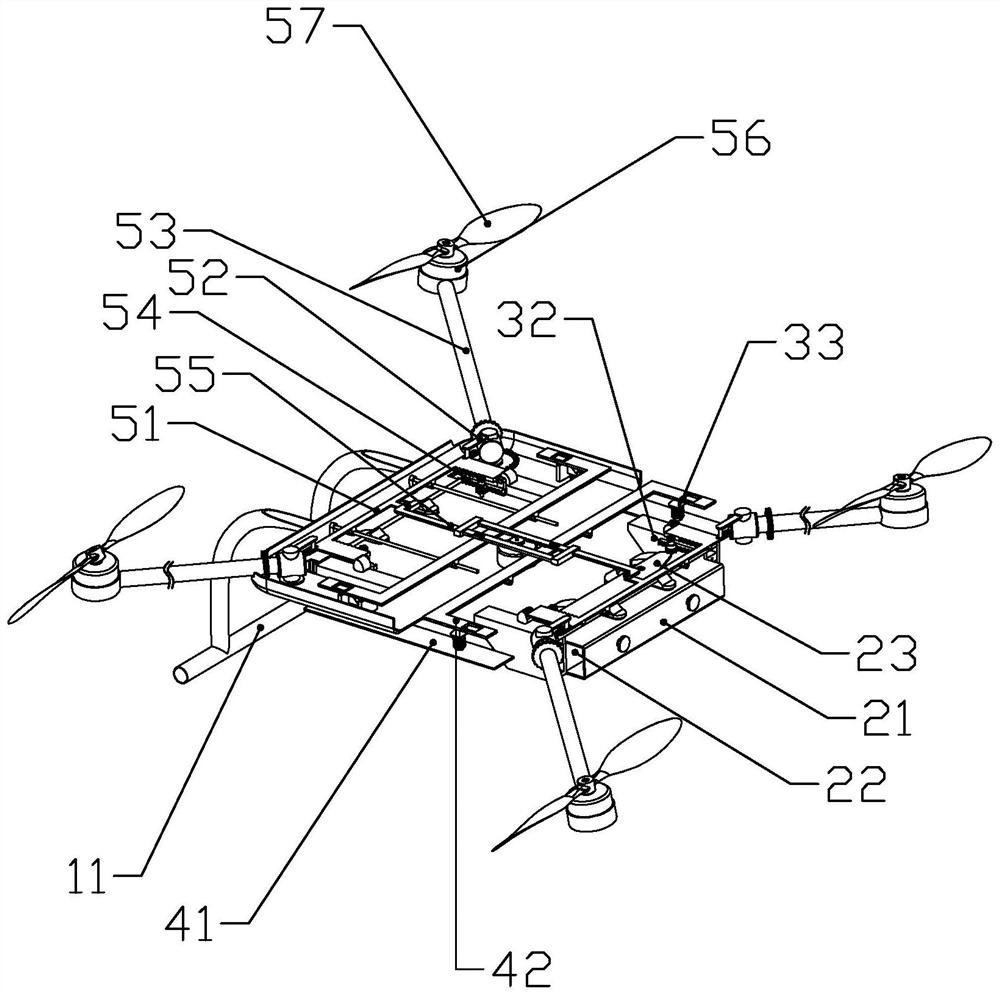

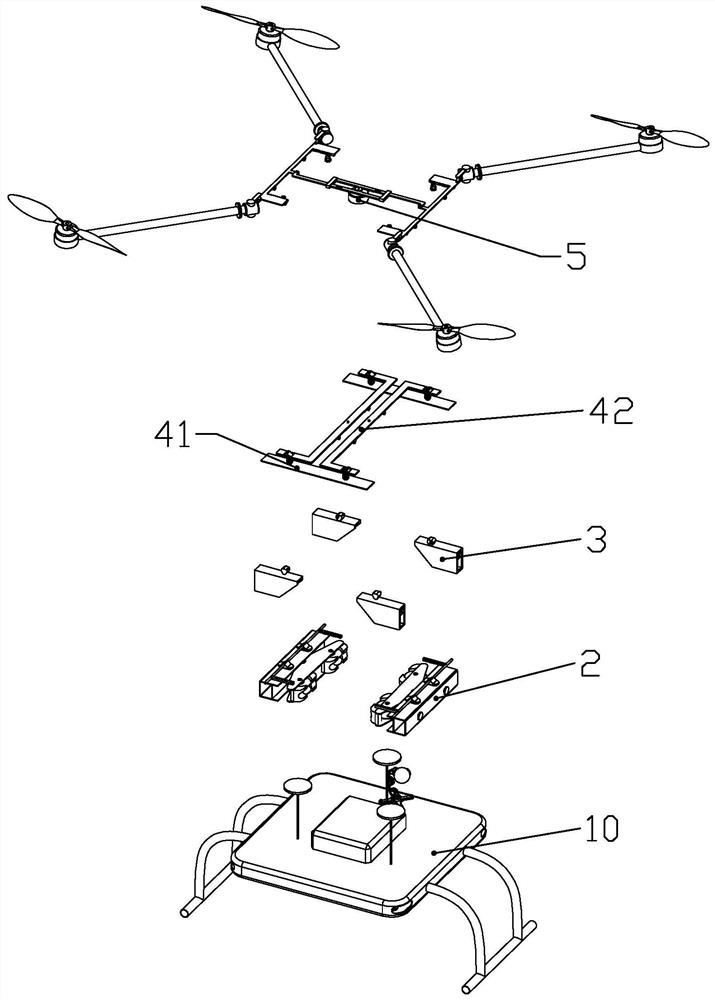

[0050] according to Figure 1 to Figure 10 As shown, a transmission line inspection robot described in this embodiment includes a casing 10 and two crawling assemblies 2 symmetrically arranged at the lower part of the casing 10 and capable of crawling on high-voltage lines; the crawling assemblies 2 It includes a sliding case 21 slidably connected to the lower part of the housing 10 in the left and right direction, and two crimping wheels 24 that are arranged longitudinally on the rotating shafts that are rotatably connected in the sliding case 21 and can be pressed against the wire; The lower part of the body 10 is provided with a landing gear 11 .

[0051] The housing 10 is provided with a flying assembly 5 for driving the housing 10 to fly; the flying assembly 5 includes four groups of flying parts evenly arranged on the housing 10; the flying parts include rotating The machine arm 53 that is connected to the rotating shaft in the housing 10 is arranged longitudinally, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com