Prefabricated concrete pavement slab structure for rapid pavement repair and construction method thereof

A prefabricated concrete and concrete slab technology, applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problems of inability to quickly restore traffic, poor connection effect, etc., and achieve short construction time, fast hardening speed, and rapid recovery. The effect of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

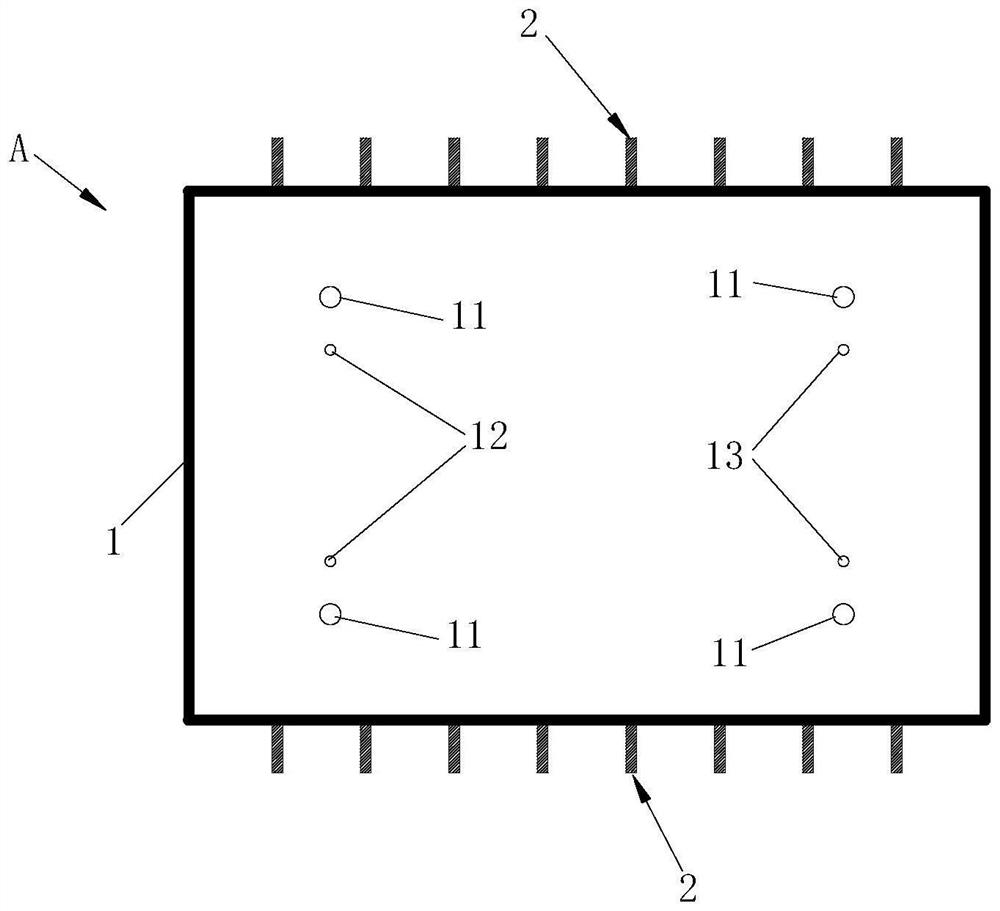

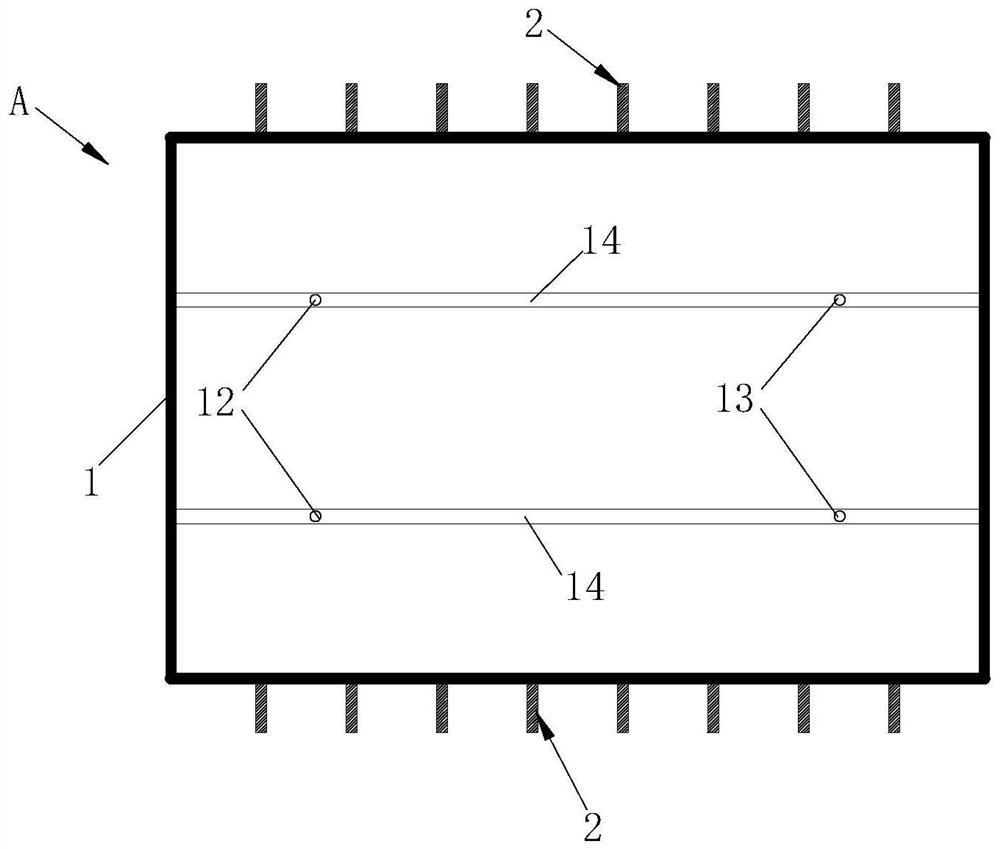

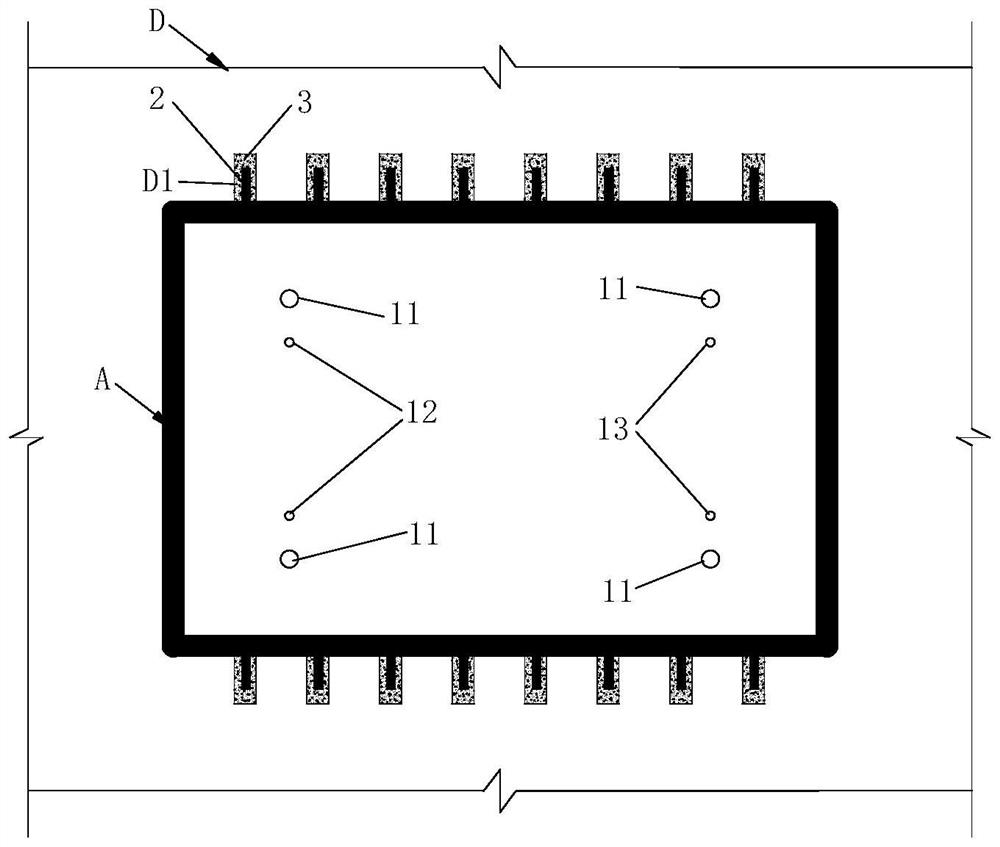

[0051] Please see figure 1 and figure 2 , shows a prefabricated concrete road slab A for quick road surface repair provided by this embodiment, including a concrete slab body 1, and a steel mesh sheet is arranged inside the concrete slab body 1; Some dowel bars 2 are provided, and some dowel bars 2 are arranged at intervals, and the four sides of the concrete slab body 1 can all be provided with dowel bars 2 .

[0052] The concrete slab body 1 is provided with several slab bottom grouting holes 11, slab bottom grouting holes 12 and hoisting holes 13, wherein the slab bottom grouting holes 11 and the slab bottom grouting holes 12 are all through holes, which are connected to the concrete slab body 1. The bottom of the board is provided with a grouting diversion groove 14 communicating with the bottom grouting hole 11 and the grouting hole 12 at the bottom of the board.

[0053] Please see image 3 , the present embodiment also provides a construction method for quickly repair...

Embodiment 2

[0063] Please see Figure 6 , shows the second type of precast concrete pavement B for rapid pavement repair provided by this embodiment. Compared with Implementation 1, the difference lies in:

[0064] The side of the concrete slab body 1 in this embodiment is provided with anchoring tenons and grooves 15, and several anchoring tenons and grooves 15 are arranged at intervals, and the four sides of the concrete slab body 1 can be provided with anchoring tenons and grooves 15.

[0065] On the concrete slab body 1 corresponding to the position of the anchoring tenon and groove 15, there are tenon and groove grouting holes 16 and tenon and groove grouting holes 17, and the tenon and groove grouting holes 16 and the tenon and groove grouting holes 17 are through holes; The top surface is wider than the bottom surface.

[0066] This embodiment also provides a construction method for quickly repairing the road surface using the above-mentioned prefabricated concrete road slab B, co...

Embodiment 3

[0076] Please see Figure 8 , which shows the third precast concrete pavement slab for rapid pavement repair provided by this embodiment. Compared with Implementation 1, the difference lies in:

[0077] Please see Figure 9 The prefabricated concrete road slab C of the present embodiment is equipped with a connecting plate 6, and the groove on the side of the concrete slab body 1 is a slab groove 18, and the top surface of the slab groove 18 has an opening corresponding to the top surface of the concrete slab body 1.

[0078] Plate groove 18 depth and width are all slightly larger than connecting plate 6, and the length of plate groove 18 is slightly longer than 1 / 2 of connecting plate 6 lengths.

[0079] This embodiment also provides a construction method for quickly repairing the road surface using the above-mentioned prefabricated concrete road slab C, comprising the following steps:

[0080] Step S1: In the factory, produce precast concrete pavement C according to the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com