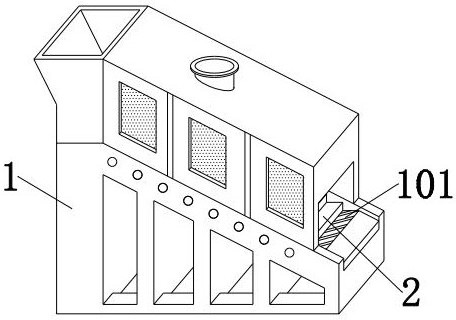

Physical cooling equipment and method for incinerator for household garbage incineration treatment

A technology of domestic waste incineration and physical cooling, applied in the field of incinerators, can solve the problems of temperature damage of waste combustion fire, inability to control the temperature of the grate effectively, and achieve effective and rapid cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

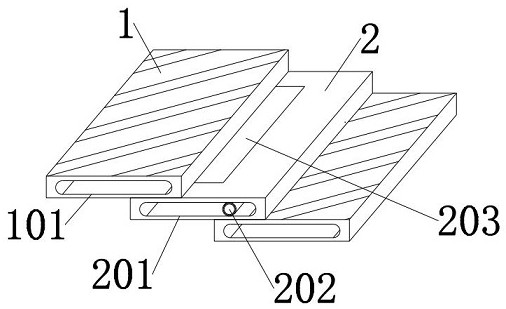

[0026] Preferred implementation mode: the fixed grate 101 includes a cooling groove 1011, a deflecting plate 1012 and an abutment groove 1013, the cooling groove 1011 is a rectangular groove in the middle of the fixed grate 101, and the deflecting plate 1012 is embedded in the middle through a circular shaft. The rectangular plate is arranged at the bottom end of the middle part of the cooling tank 1011, and the contact groove 1013 is a rectangular groove extending obliquely near the bottom end of one side of the deflection plate 1012.

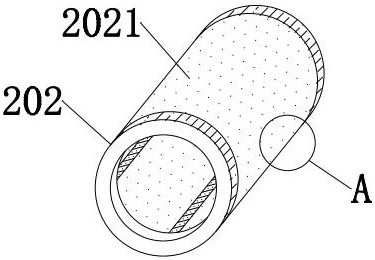

[0027] Preferred implementation mode: the movable grate 2 includes a water flow tank 201, a water storage shaft 202 and a flipping plate 203, the water flow tank 201 is a rectangular groove in the middle of the movable fire grate 2, and the water storage shaft 202 is a water flow tank with the same diameter as the water flow tank. 201 is a hollow circular shaft fitted with a width, and one end of the water storage shaft 202 communicates with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com