Exhaust gas purification device for CVD process

A technology of exhaust gas purification device and process, applied in chemical instruments and methods, dispersed particle separation, use of liquid separation agents, etc., can solve the problems of occupying purification room space, reducing purification efficiency, and bulky volume, etc., and achieves rapid and effective cooling and high efficiency. The effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Presented below are some of the many possible embodiments of the invention, intended to provide a basic understanding of the invention. It is not intended to identify key or critical elements of the invention or to delineate the scope of protection.

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

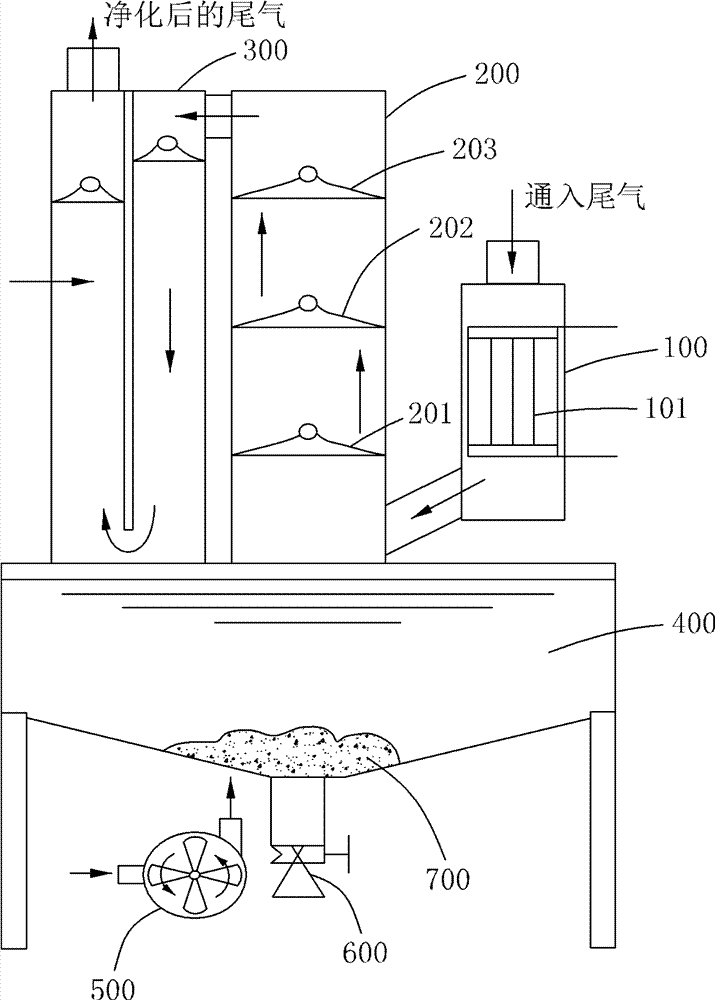

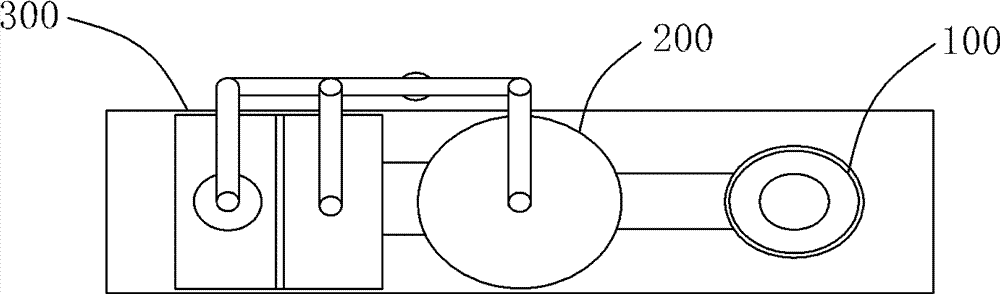

[0031] figure 1 is a schematic diagram showing the structure of the exhaust gas purification device of the CVD process of the present invention. figure 2 is a schematic plan view showing the exhaust gas purification device of the CVD process of the present invention.

[0032] Such as figure 1 As shown, the tail gas purification device of the CVD process of the present invention mainly includes: a high temperature reaction barrel 100 , a cooling absorption tower 200 , a purification adsorption tower 300 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com