Substrate transfer device

A substrate conveying and conveying arm technology, which can be applied to conveyor objects, transportation and packaging, electrical components, etc., and can solve problems such as low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

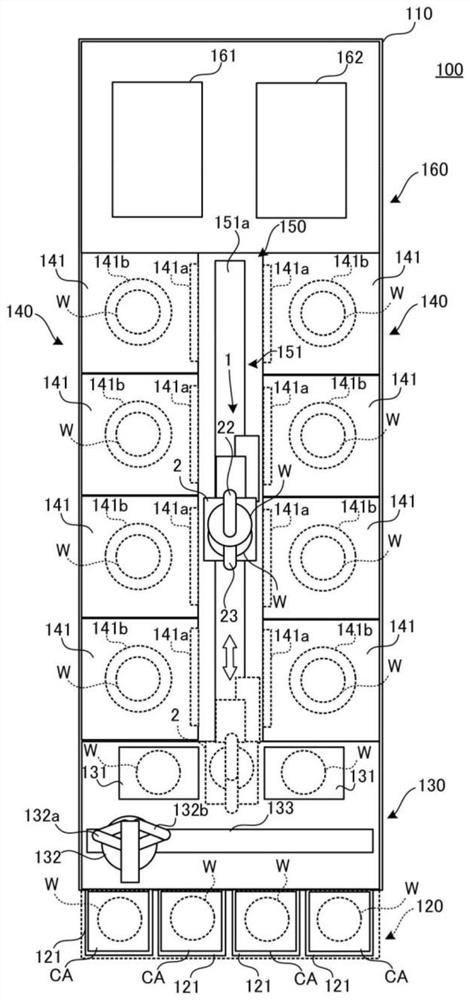

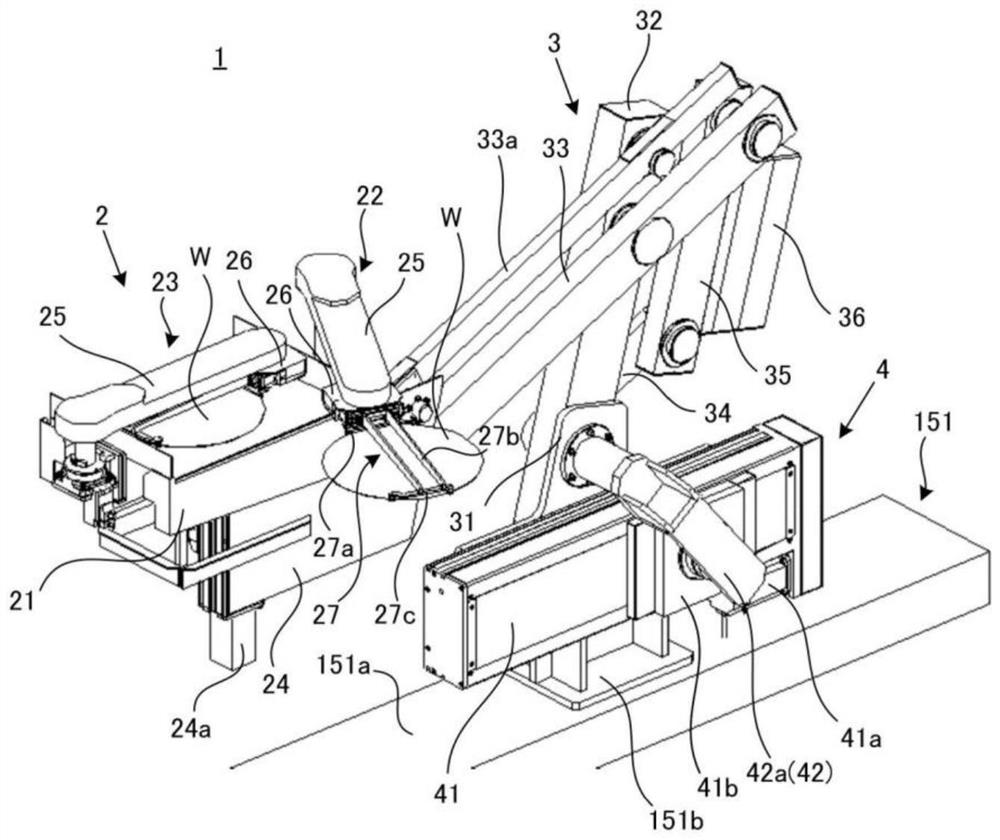

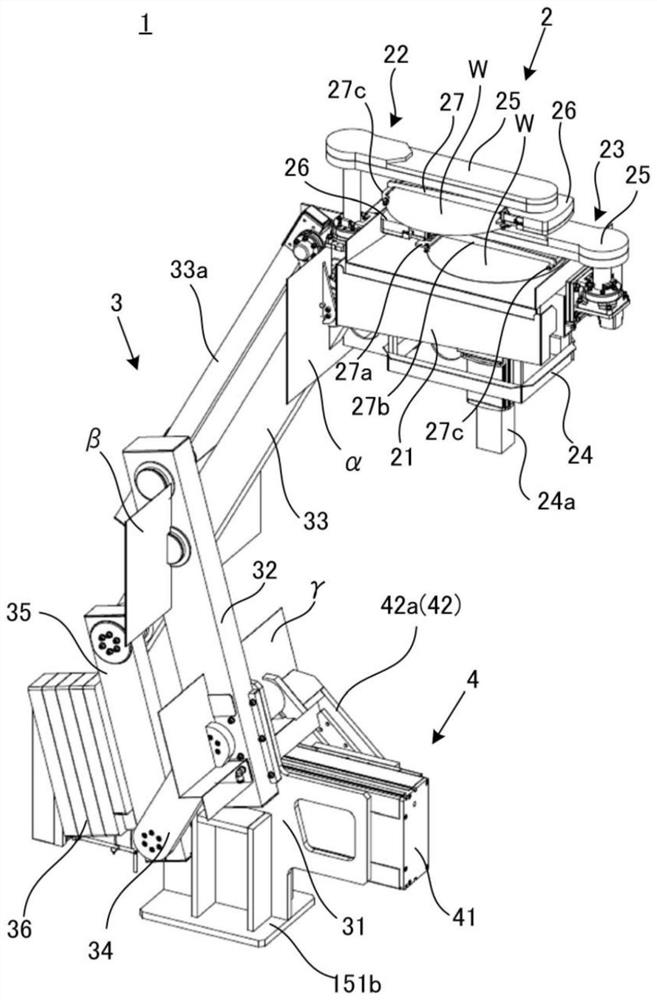

[0087] A substrate transfer device according to an embodiment and a substrate processing device to which the substrate transfer device according to the embodiment is applied will be described with reference to the drawings.

[0088] [Substrate Processing Equipment]

[0089] First, refer to figure 1 and figure 2 The outline of the substrate processing apparatus 100 to which the substrate transfer apparatus 1 of this embodiment is applied will be described. figure 1 It is a plan view showing the overall structure of the substrate processing apparatus 100 . figure 2 It is a perspective view of the substrate transfer device 1 . The substrate processing apparatus 100 includes a chamber 141 for processing a plurality of substrates, and processes a plurality of substrates W stored in a cassette CA (FOUP) and transported in the previous step in each chamber 141 one by one. device for piece-by-piece processing. The substrate W is, for example, a disk-shaped semiconductor wafer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com