Spliced cabinet

A pair of cabinet technology, applied in the field of splicing cabinets, can solve the problems of poor waterproof and moisture-proof performance, high processing and production costs, and large overall weight of the cabinet, so as to improve the overall panel strength, reduce the overall weight, and achieve reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

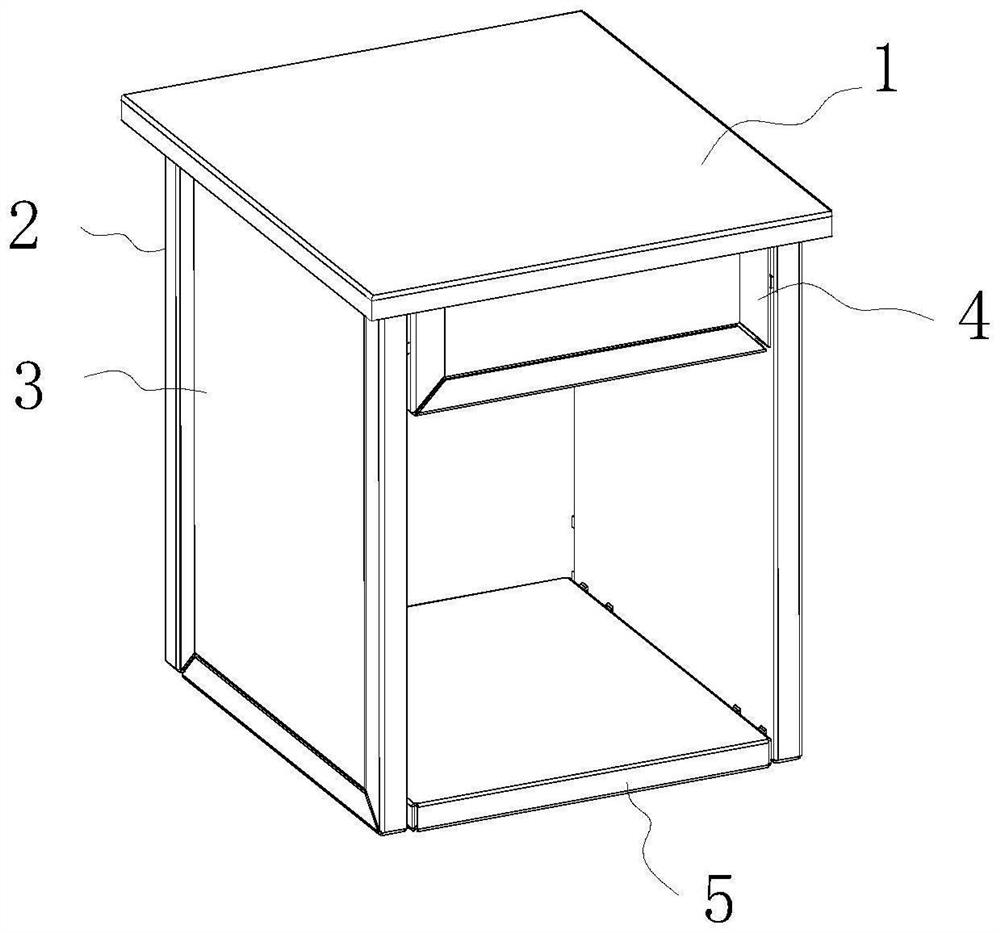

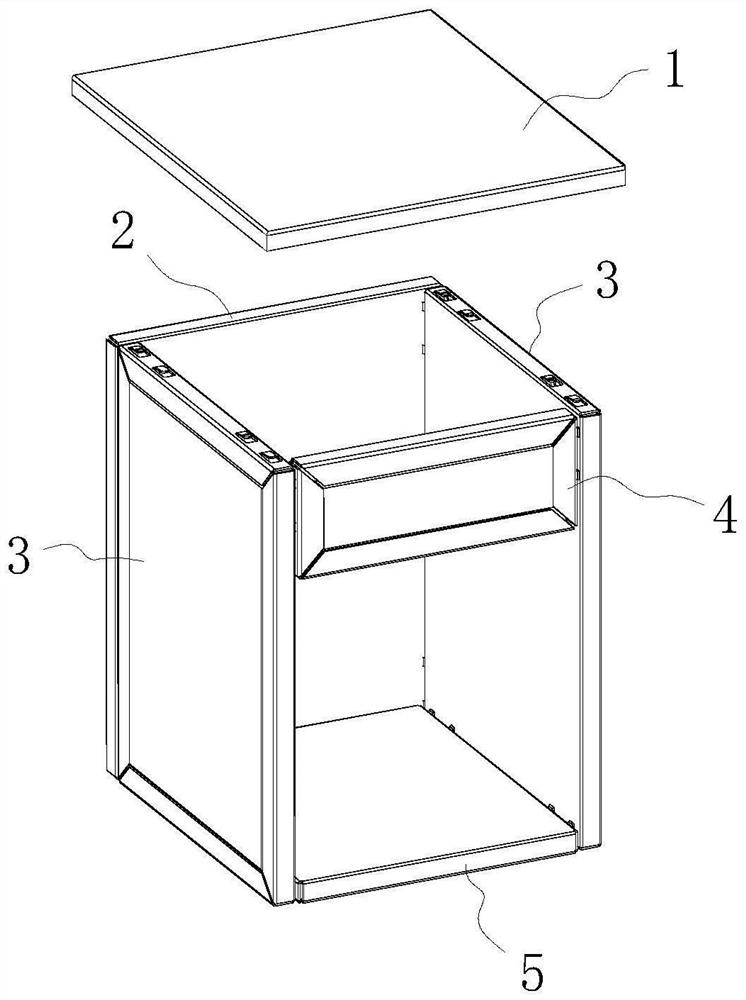

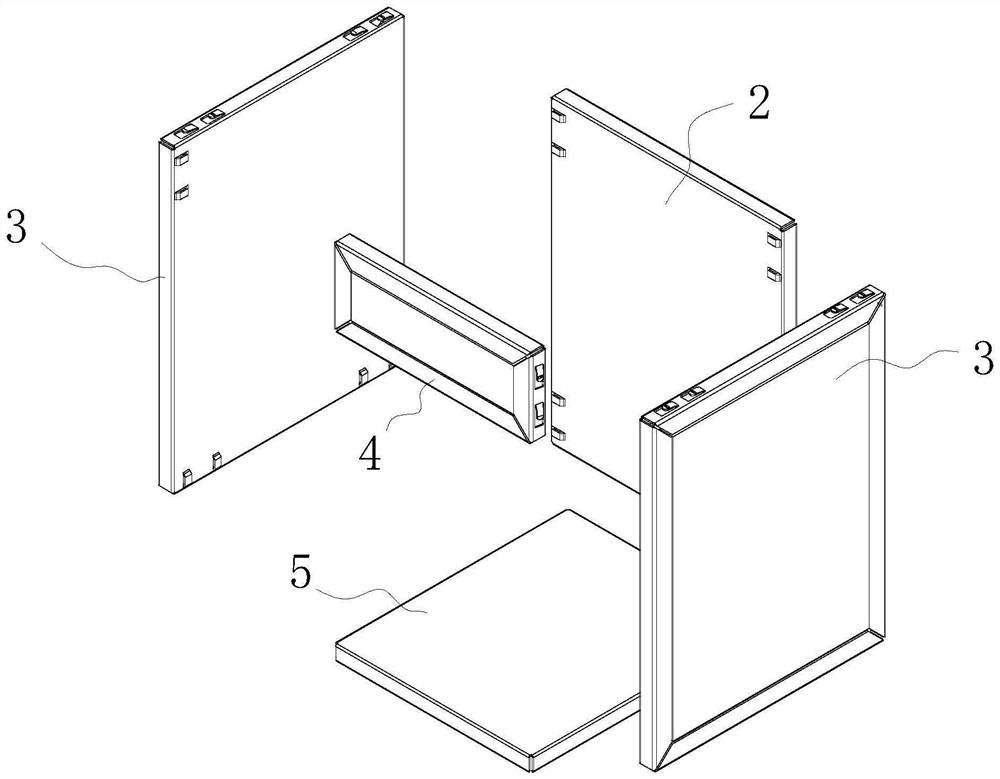

[0040] Example 1: See Figure 1-7 , a splicing cabinet, comprising a sheet metal back panel 2, a sheet metal side panel 3, a cabinet body sheet metal top panel 1, a sheet metal bottom panel 5, and a sheet metal crossbeam 4, the left and right sides of the end face inner wall of the sheet metal back panel 2 Distributed with at least one pair of buckle parts 9;

[0041] The end inner wall in this embodiment refers to the end wall corresponding to the sheet metal back panel 2 , the sheet metal side panel 3 , the sheet metal bottom panel 5 , and the sheet metal beam 4 corresponding to the cabinet cavity.

[0042] The edge of the side wall of the sheet metal side plate 3 near the sheet metal back plate 2 is provided with at least one pair of inserting parts 8 for cooperating with the buckle part 9, and the lower end of the end face inner wall of the sheet metal side plate 3 is provided with at least one For the buckle parts 9, at least one pair of buckle parts 9 are distributed on...

Embodiment 2

[0055] Example 2: see Figure 8 , a splicing cabinet, the difference from Embodiment 1 is that it also includes a horizontal sheet metal partition 7 and a vertical sheet metal partition 6, and the side walls on the left and right sides of the horizontal sheet metal partition 7 are provided with sockets 8. The buckle part 9 corresponding to the insertion part 8 of the horizontal sheet metal partition 7 is arranged on the inner wall of the sheet metal side panel 3 and / or the end wall of the vertical sheet metal partition 6;

[0056] In this embodiment, the buckle part 9 corresponding to the insertion part 8 of the horizontal sheet metal partition 7 is arranged on the end face inner wall of the sheet metal side plate 3 and the end face wall of the vertical sheet metal partition 6 at the same time. The insertion part 8 on the left side of the sheet metal partition 7 is inserted into the buckle part 9 of the sheet metal side panel 3, and the insertion part 8 on the right side of th...

Embodiment 3

[0061] Example 3: See Figure 9-10 , a splicing cabinet, the difference from embodiment 2 is that the sheet metal back panel 2, the sheet metal side panel 3, the sheet metal bottom panel 5 and the sheet metal beam 4 all adopt the same sheet metal structure of the overall sheet metal, and the sheet metal The metal plate includes a sheet metal shell and a sheet metal outer cover shell. The sheet metal shell includes a sheet metal base plate 100 as the inner wall of the end face. The sides of the sheet metal base plate 100 are bent and extended to have side wall edges 101. The side wall of the edge 101 is bent and extended to have an end face edge 102, and the end face edge 102 is bent and extended to have an inner side wall edge 103 close to the sheet metal base plate 100;

[0062] The edge 103 of the inner side wall and the sheet metal base plate 100 form a sheet metal outer insert groove, and the sheet metal outer cover shell is embedded in the sheet metal outer insert groove,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com