Gas premixing distributor

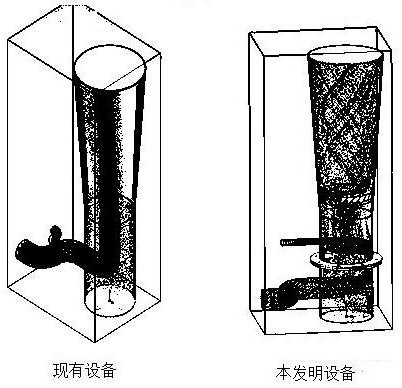

A distributor and pre-mixing technology, applied in the direction of gas and gas/vapor mixing, fluid mixer, mixer, etc., can solve the problem of uneven mixing of three gases, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

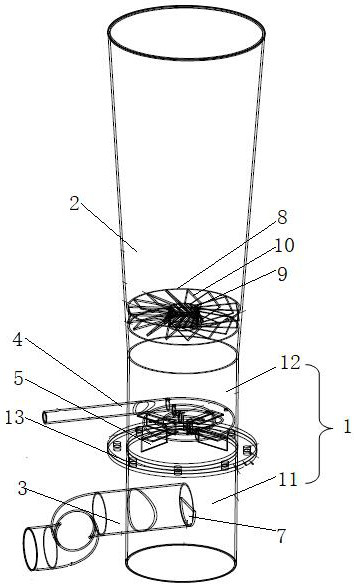

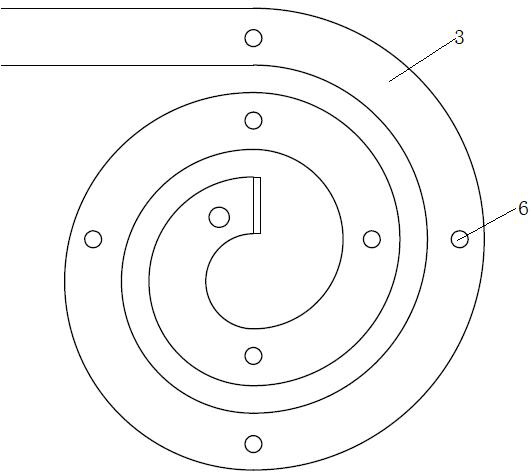

[0020] like figure 1 and figure 2 Shown is a gas premixing distributor provided by the present invention, which is installed at the lower part of the burner for premixing exhaust gas, assisted gas and air, including a gas injection cylinder section 1 for gas injection, and for gas Mixed and discharged cone diffuser section 2, the lower end of gas injection cylinder section 1 is used as air inlet, the outlet of gas injection cylinder section 1 communicates with the small end of cone diffuser section 2, and the gas injection section 1 and cone diffuse A swirl plate assembly for gas turbulent mixing is arranged at the junction of the cylinder section 2, and an auxiliary gas inlet pipeline 3, an exhaust gas inlet pipeline 4, an auxiliary g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com