High-strength steel plate steel pipe pile butt joint circumferential weld welding method

A high-strength steel plate and welding method technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of not giving groove size, welding preheating welding sequence, welding material weld seam hammering, weld seam heat treatment technology Measures, can not effectively prevent cold cracks and other problems, to achieve the effect of improving the pass rate of flaw detection, avoiding welding cold cracks, and ensuring the quality of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

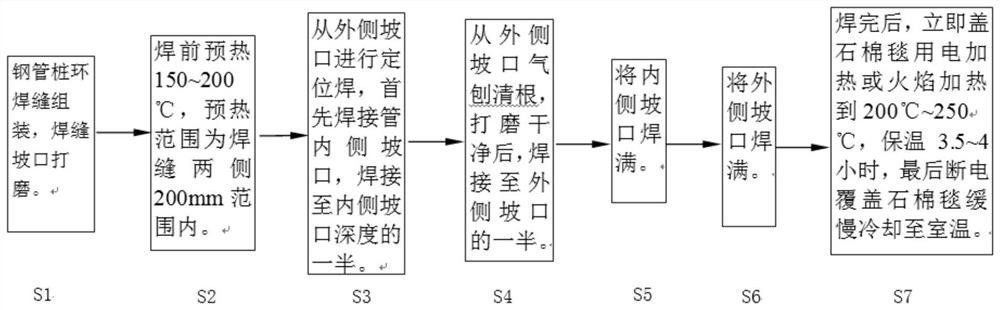

[0034] An embodiment of the present invention provides a high-strength steel sheet steel pipe pile butt girth welding method, the method may include:

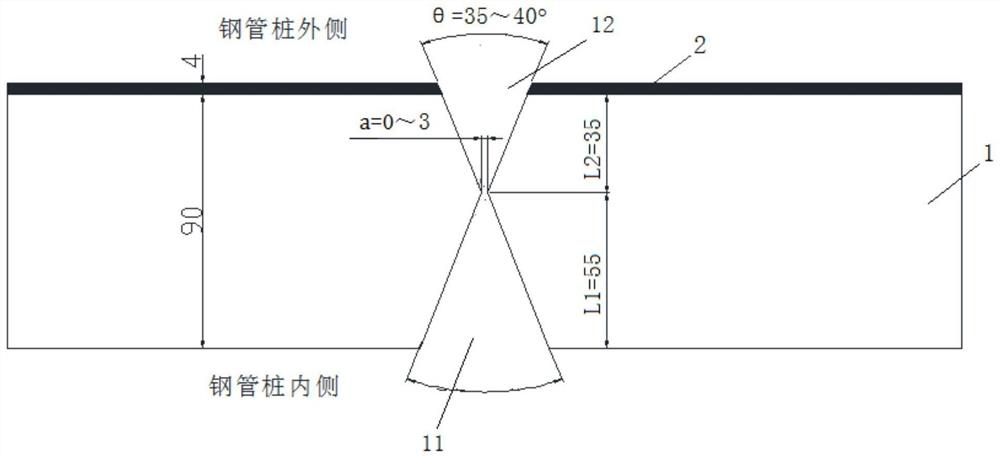

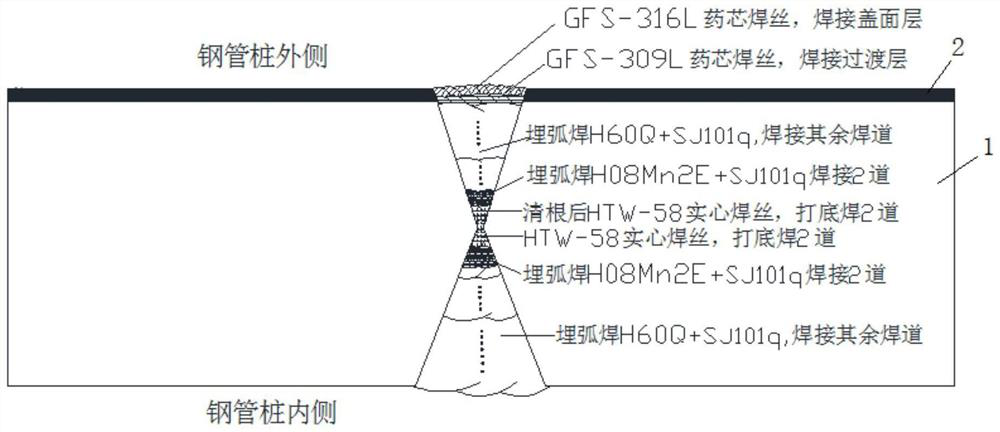

[0035] Before welding, polish the groove surface and the 20-30 mm on both sides of the weld to expose the metallic luster. Set an X-shaped groove on the opposite end face of the butt girth weld of the 500MPa extra-thick steel plate 1 steel pipe pile; the depth L1 of the inner groove 11 located on the inner side of the steel pipe pile is greater than the outer groove located on the outer side of the steel pipe pile 12 Depth L2, so that the X-shaped groove forms an asymmetric form in the inner and outer direction of the steel pipe pile; the groove angle θ of the X-shaped groove is 35-40°, and the root gap a is 0-3 mm; further, the ratio of the inner groove depth L1 to the outer groove depth L2 is 11:7.

[0036] The steel pipe pile is preheated before welding, and the preheating temperature is 150-200°C; specifically, the steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com