Tool trolley with turnable and fixed tool apron for five-axis machining center

A five-axis machining center, cutting tool technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of tool damage, stabbing staff, easy cuts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

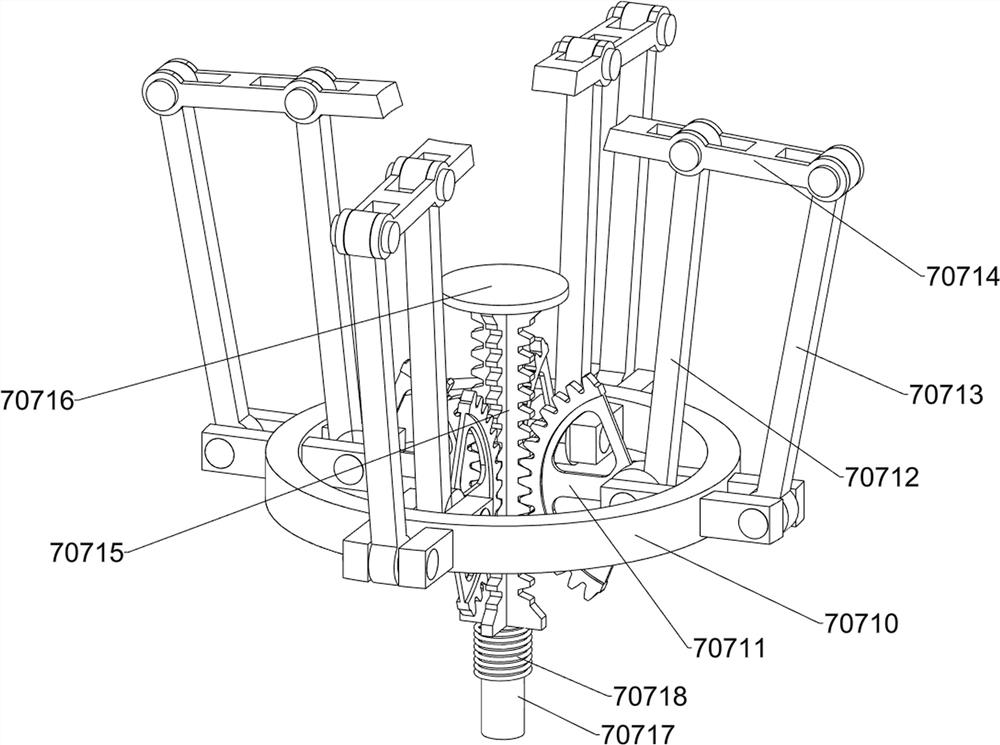

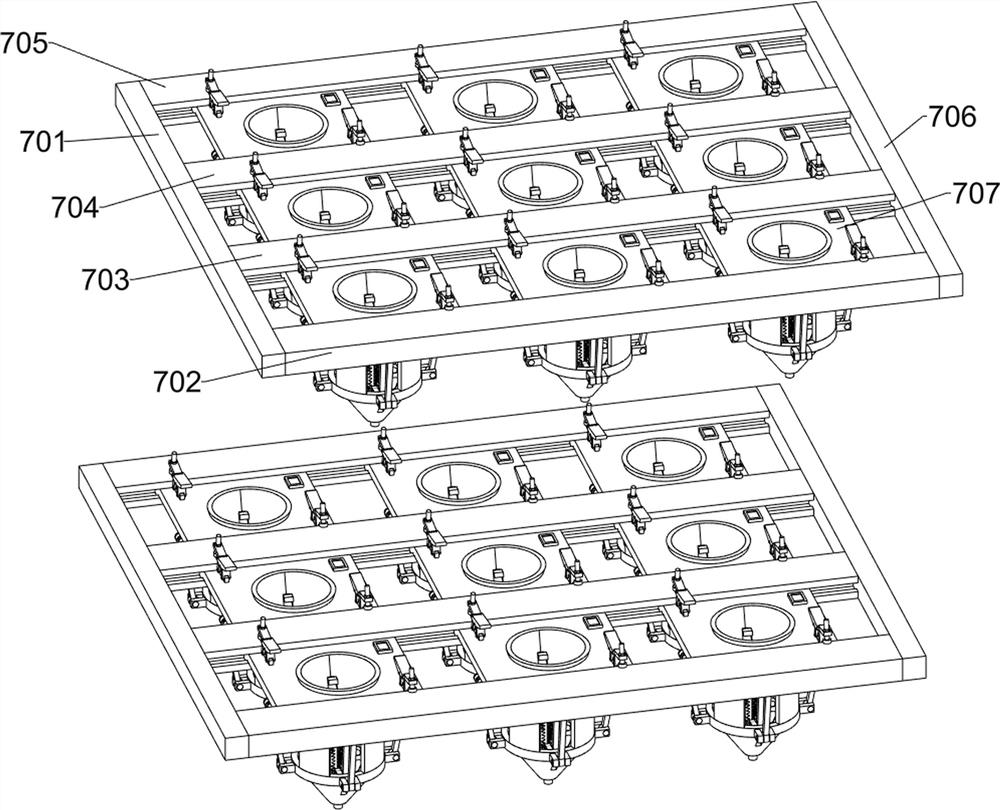

[0040] A tool car with a reversible and fixed tool seat for a five-axis machining center, such as Figure 1-3 As shown, it includes a vehicle frame 1, a first handle 2, a second handle 3, a first control panel 4, a first storage box 5, a turning mechanism 6, a storage mechanism 7, a cleaning mechanism 8, a first collection box 9, a third The handle 10 and the first universal wheel 11; the upper left side of the vehicle frame 1 is provided with the first handle 2 and the second handle 3 in turn; the upper left side of the vehicle frame 1 is installed with the first control panel 4; the upper left side of the vehicle frame 1 The first storage box 5 is installed; the interior of the vehicle frame 1 is provided with an overturning mechanism 6; the upper part of the vehicle frame 1 is fixedly connected with the cleaning mechanism 8; the lower part of the vehicle frame 1 is provided with a first collection box 9; A set of first universal wheels 11 are provided; the turning mechanism...

Embodiment 2

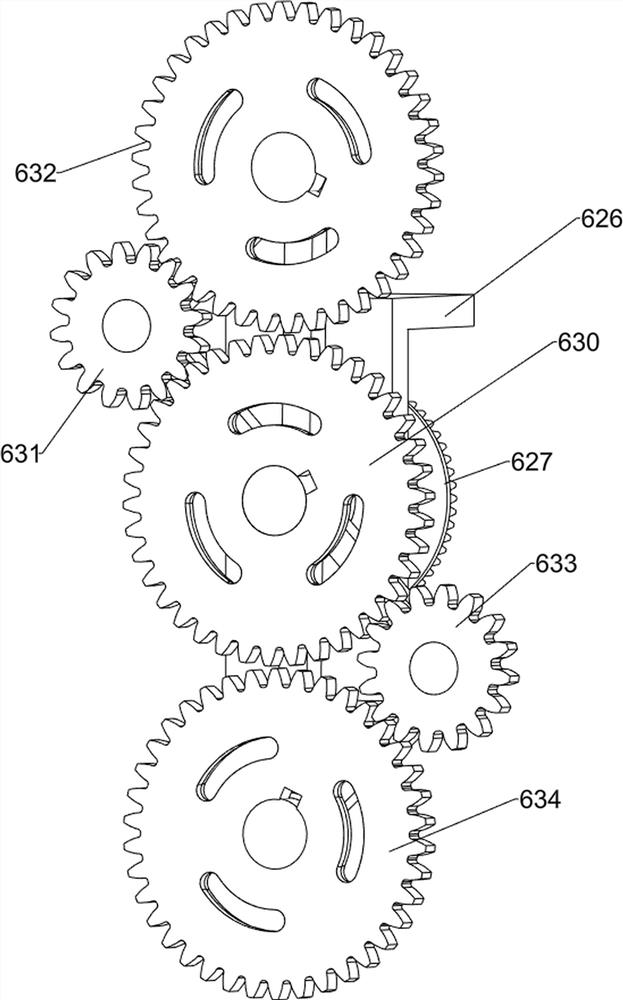

[0043] On the basis of Example 1, such as figure 1 and Figure 4-19As shown, the turning mechanism 6 includes a first support plate 601, a first motor 602, a first bevel gear 603, a second bevel gear 604, a first transmission rod 605, a first support frame 606, a third bevel gear 607, a first Four bevel gears 608, the second transmission rod 609, the fifth bevel gear 610, the second support frame 611, the sixth bevel gear 612, the first connecting frame 613, the third transmission rod 614, the first straight gear 615, the second straight gear Gear 616, third spur gear 617, fourth spur gear 618, fifth spur gear 619, seventh bevel gear 620, fourth transmission rod 621, eighth bevel gear 622, ninth bevel gear 623, fifth transmission rod 624 , the tenth bevel gear 625, the third support frame 626, the eleventh bevel gear 627, the second connecting frame 628, the sixth transmission rod 629, the sixth spur gear 630, the eighth spur gear 631, the ninth spur gear 632, The tenth spur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap