Supercritical carbon dioxide foaming preparation device and foaming preparation method for low-dielectric-constant polyimide microporous film

A low dielectric constant, microporous film technology, which is applied in the field of low dielectric constant polyimide microporous film preparation equipment and preparation, can solve the problems of rare polyimide microporous film equipment, and achieve rapid Efficient preparation, less operation process and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

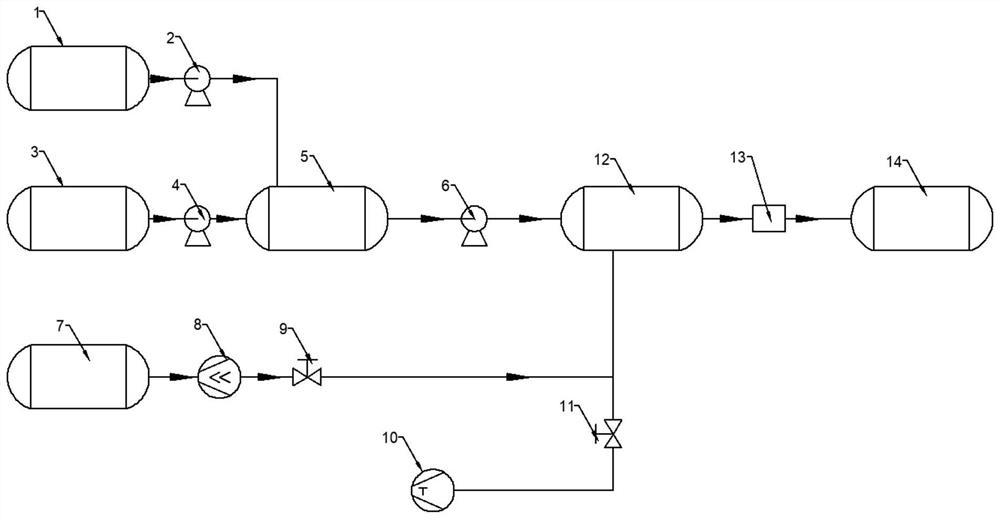

[0030] Connect each device in turn, turn on the metering pump I (2) and metering pump II (4) to mix the N, N-dimethylacetamide solvent and the polyamide in the N,N-dimethylacetamide solvent tank (1) The polyamic acid solution in the acid solution tank (3) is injected into the batching tank (5) to be configured as a 25% mass fraction polyamic acid solution.

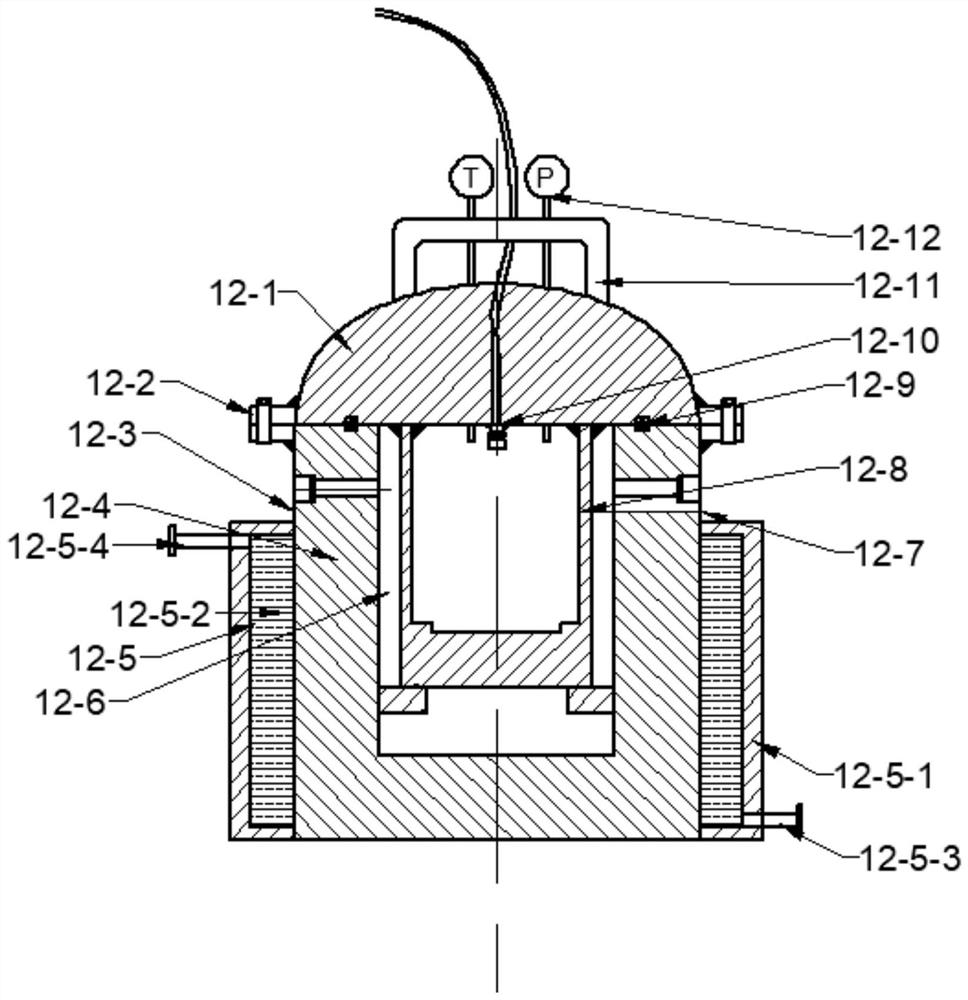

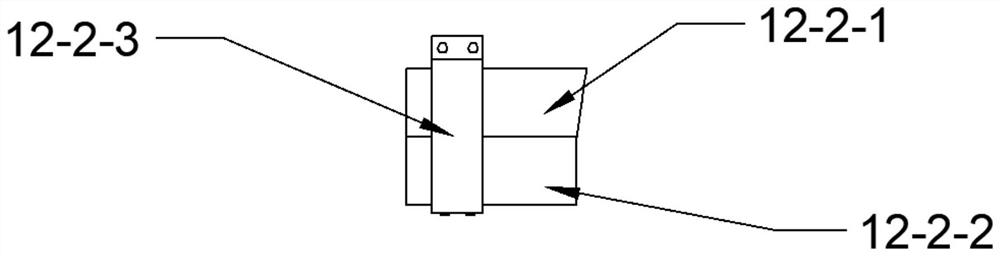

[0031] Close the metering pump I (2) and the metering pump II (4), open the metering pump III (6), and pass the polyamic acid solution configured in the batching kettle (5) through the connecting hose (12-14) and the spray gun (12 -10) Evenly spray to the spray plate (12-8).

[0032] Open the vacuum pump (10) and high-pressure valve II (11), vacuumize the autoclave (12), then close the vacuum pump (10) and high-pressure valve II (11), and heat the oil through the heat transfer oil inlet (12-5-3 ) into the heat conduction oil chamber (12-5-2) of the jacket (12-5), heat the sprayed plate to 80°C and maintain it for 2 hours,...

Embodiment example 2

[0037] Connect each device in turn, turn on the metering pump I (2) and metering pump II (4) to mix the N, N-dimethylacetamide solvent and the polyamide in the N,N-dimethylacetamide solvent tank (1) The polyamic acid solution in the acid solution tank (3) is injected into the batching tank (5) to be configured as a 25% mass fraction polyamic acid solution.

[0038] Close the metering pump I (2) and the metering pump II (4), open the metering pump III (6), and pass the polyamic acid solution configured in the batching kettle (5) through the connecting hose (12-14) and the spray gun (12 -10) Evenly spray to the spray plate (12-8).

[0039] Open the vacuum pump (10) and high-pressure valve II (11), vacuumize the autoclave (12), then close the vacuum pump (10) and high-pressure valve II (11), and heat the oil through the heat transfer oil inlet (12-5-3 ) into the heat conduction oil chamber (12-5-2) of the jacket (12-5), heat the sprayed plate to 80°C and maintain it for 2 hours,...

Embodiment example 3

[0044] Connect each device in turn, turn on the metering pump I (2) and metering pump II (4) to mix the N, N-dimethylacetamide solvent and the polyamide in the N,N-dimethylacetamide solvent tank (1) The polyamic acid solution in the acid solution tank (3) is injected into the batching tank (5) to be configured as a 25% mass fraction polyamic acid solution.

[0045] Close the metering pump I (2) and the metering pump II (4), open the metering pump III (6), and pass the polyamic acid solution configured in the batching kettle (5) through the connecting hose (12-14) and the spray gun (12 -10) Evenly spray to the spray plate (12-8).

[0046] Open the vacuum pump (10) and high-pressure valve II (11), vacuumize the autoclave (12), then close the vacuum pump (10) and high-pressure valve II (11), and heat the oil through the heat transfer oil inlet (12-5-3 ) into the heat conduction oil chamber (12-5-2) of the jacket (12-5), heat the sprayed plate to 80°C and maintain it for 2 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com