Film coating process for BOPP (biaxially-oriented polypropylene) electrical film

A process and electrical technology, applied in the field of coating process of BOPP electrical film, can solve problems such as easy to produce wrinkles, static tree lines, product deformation, etc., to achieve the effect of lengthening the moving stroke, preventing damage, and improving linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

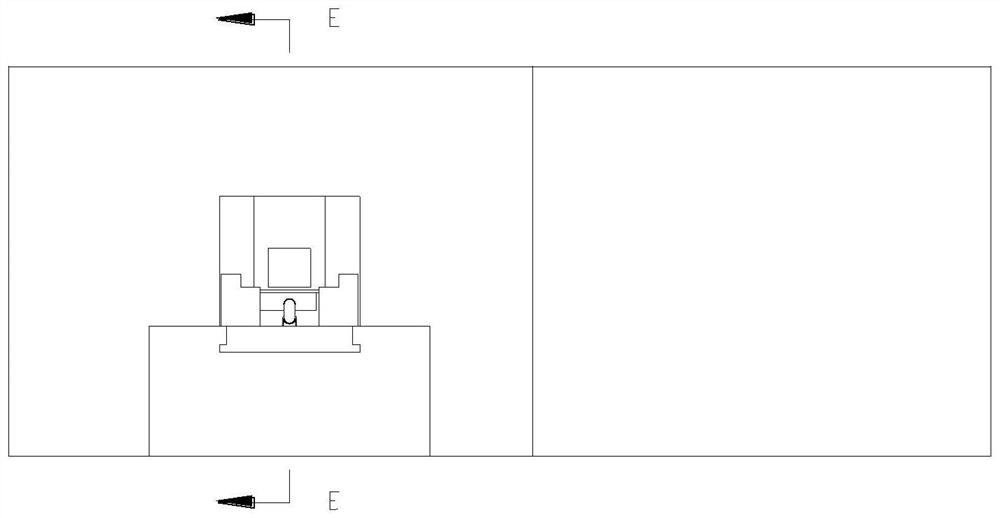

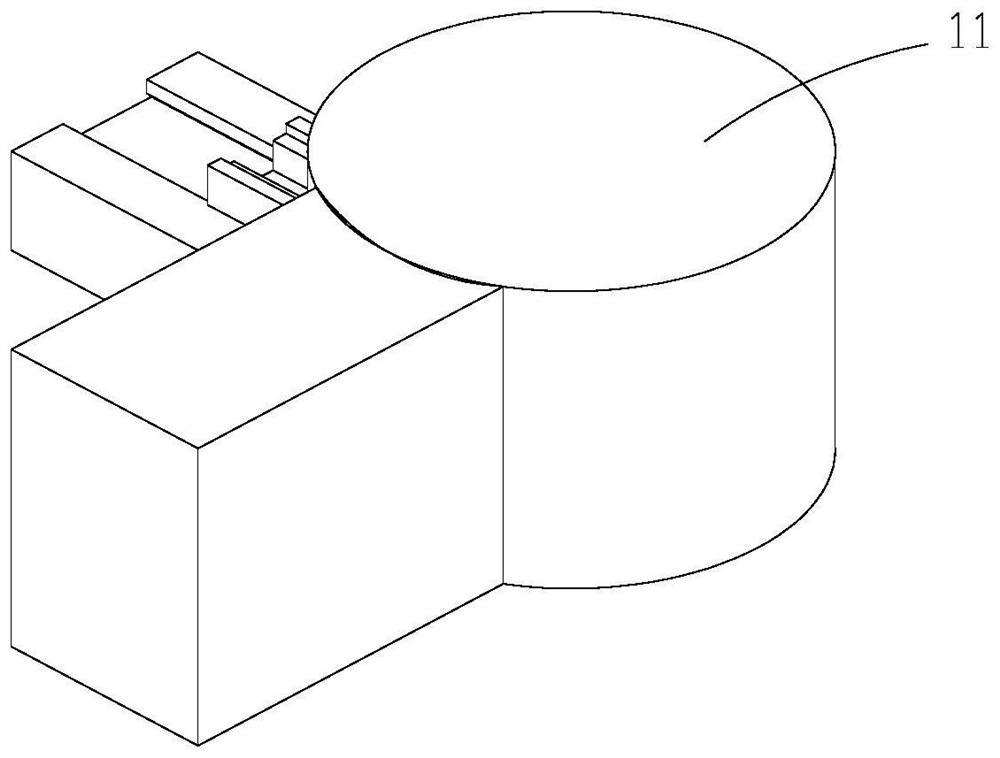

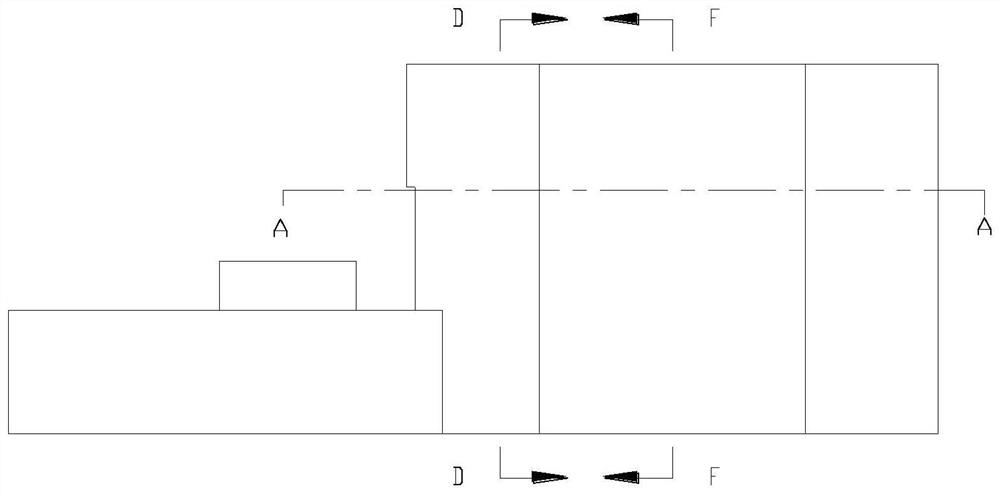

[0033] Such as Figure 1-12 Shown, a kind of coating process for BOPP electrical film, comprises the following steps:

[0034] a. Prepare accessories;

[0035] b. Sanitation of cleaning equipment;

[0036] c. Equipment preheating;

[0037] d. Use a feeder to send BOPP into the coating machine; first place the BOPP film on the moving block 10, and drive the moving block 10 to move laterally; The film is sucked on the rotating disk 21; the docking device 2 includes a rotating disk 20, a transition cavity 22, a fixed block 23, and a docking mechanism 3; the rotating disk 20 is rotatably embedded in the bottom of the transition chamber 11; the transition chamber 22 is provided with 4, the cross section is fan-shaped, is arranged on the upper end surface of rotating disc 20; Said fixed block 23 is arranged in each transition chamber 22; Said docking mechanism 3 is arranged on the fixed block 23; Before coating, transition The air extractor on the warehouse 11 starts to pump the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com