Integrated testing device for fusing characteristics of high-voltage fuse

A high-voltage fuse, comprehensive testing technology, applied in the direction of circuit breaker testing, etc., can solve the problem of lack of detection methods for the current-time characteristics of high-voltage fuses, and achieve good dynamic performance, high stability, and fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

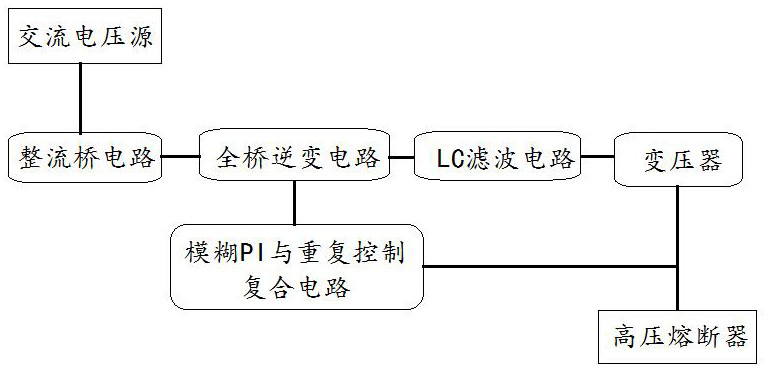

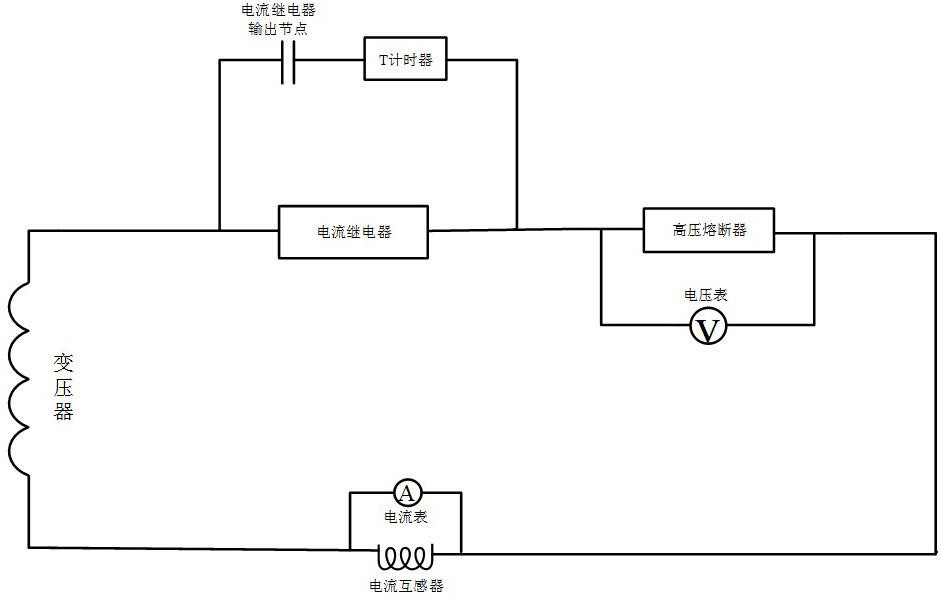

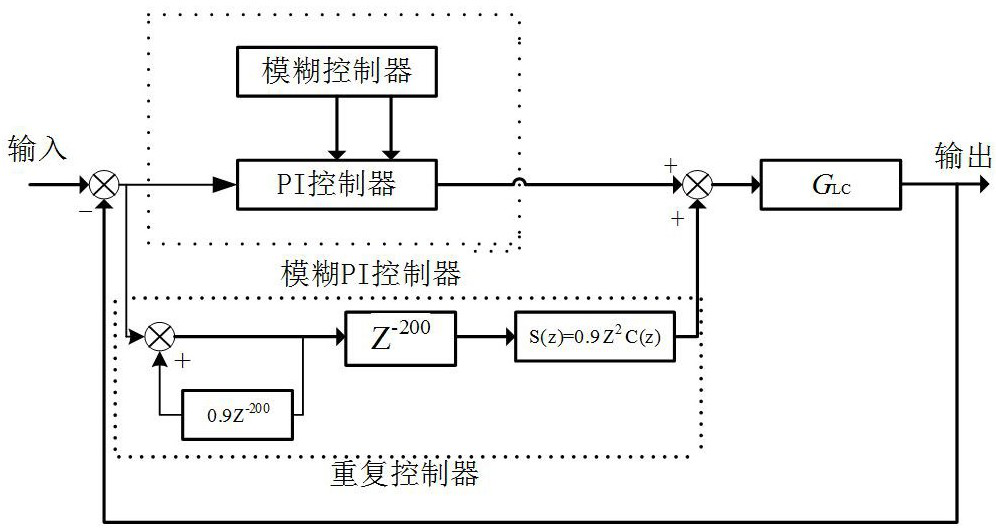

[0033] like figure 1 As shown, a high-voltage fuse fusing characteristic comprehensive testing device is set between the AC voltage source and the high-voltage fuse, including a rectifier bridge circuit, a full-bridge inverter circuit, an LC filter circuit, a transformer, a fuzzy PI and a repetitive control composite circuit The rectifier bridge circuit, the full bridge inverter circuit, the LC filter circuit and the transformer are connected in series in sequence, and the rectifier bridge circuit is also connected to the AC voltage source, and the transformer is also connected to the high-voltage fuse connected; the fuzzy PI and repetitive control composite circuit are connected to the full-bridge inverter circuit, and also connected between the transformer and the high-voltage fuse.

[0034] Specifically, the rectifier bridge circuit is used to convert the industrial frequency commercial power input by the AC voltage source into DC power and output it.

[0035]Specifically,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com