Fuel cell waste heat recovery system and vehicle

A fuel cell and waste heat recovery technology, applied in fuel cell heat exchange, fuel cell additives, electrical components, etc., can solve the problems of volume power density and mass power density decrease, occupying system volume and mass, etc., to reduce the heat dissipation burden , the effect of improving operating efficiency and reducing system costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] A vehicle, characterized by comprising a cooler, a fuel cell, and the fuel cell waste heat recovery system according to any one of claims 1-4;

[0041] The cold source side exchanges heat with the cooler.

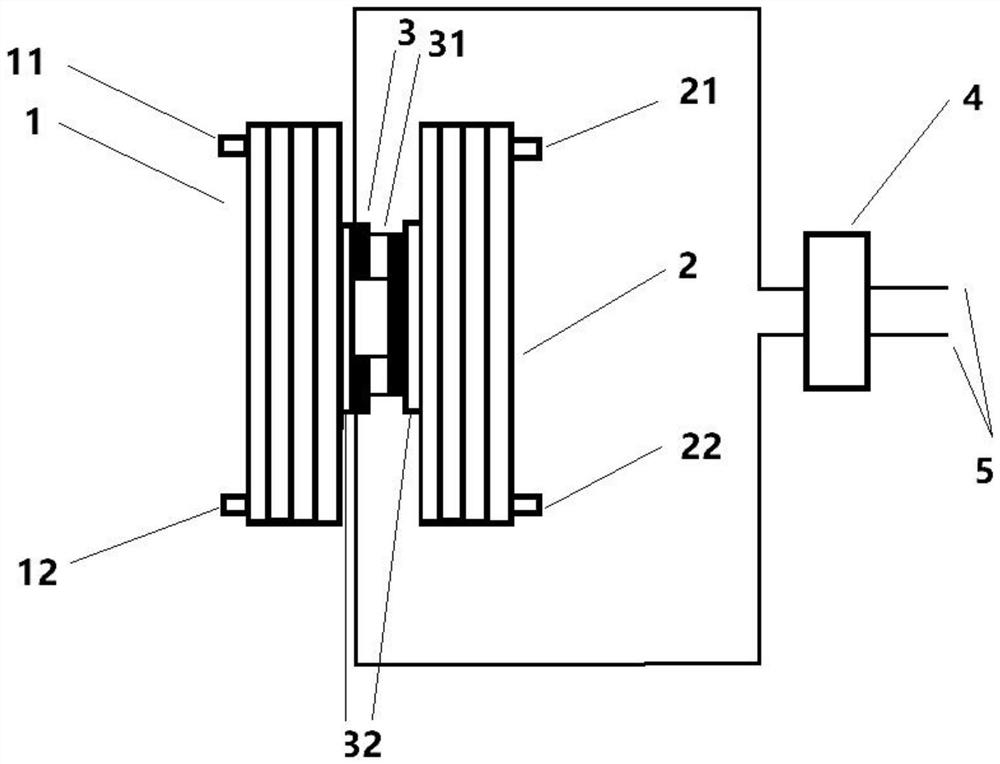

[0042] The cold source side includes a cold source box 1 and pipelines. The cold source box 1 includes a cold source fluid inlet 11 and a cold source fluid outlet 12. The device is connected; the cold source box 1 has a cold source fluid.

[0043] The fuel cell includes a cooling flow channel;

[0044] The heat source side includes a heat source box 2 and pipelines. The heat source box 2 includes a heat source fluid inlet 21 and a heat source fluid outlet 22. The heat source fluid inlet 21 and the heat source fluid outlet 22 respectively pass through the pipeline and the two ends of the cooling channel of the fuel cell. Communication; the heat source box 2 has a heat source fluid.

[0045] The vehicle also includes a controller, a temperature sensor, a first pump,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com