Efficient cooling system for mixed rubber sheet

A technology of cooling system and mixing film, applied in the direction of coating, etc., can solve the problems of high processing pressure, high production energy consumption, waste of water resources, etc., and achieve the effect of reducing air intake, reducing the burden of subsequent processing, and reducing the burden of cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

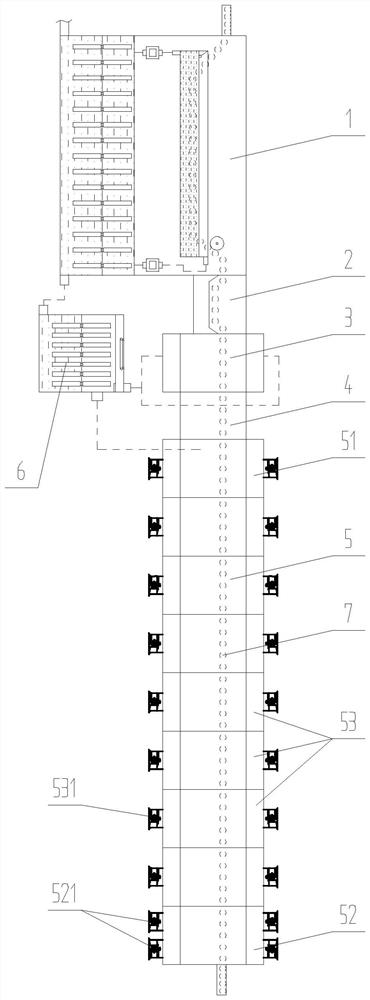

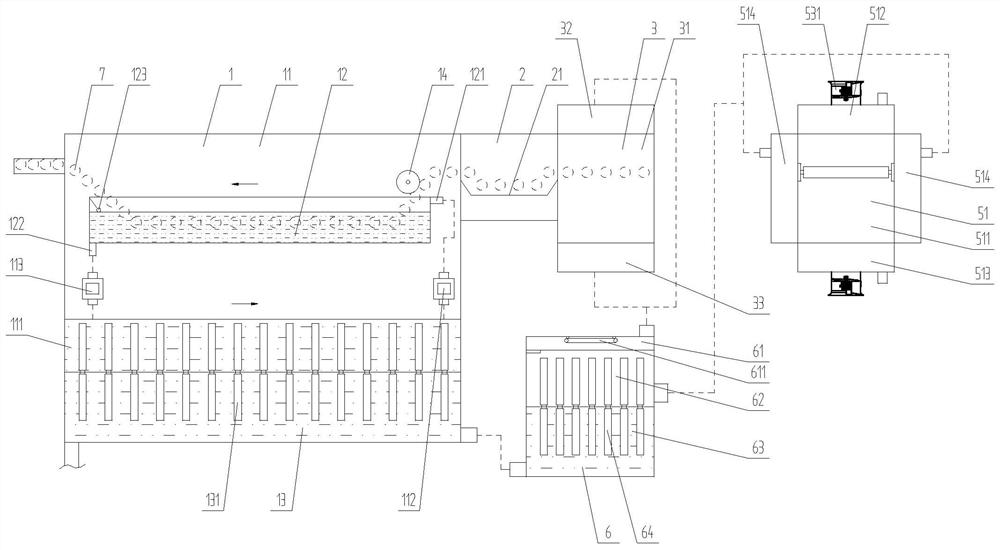

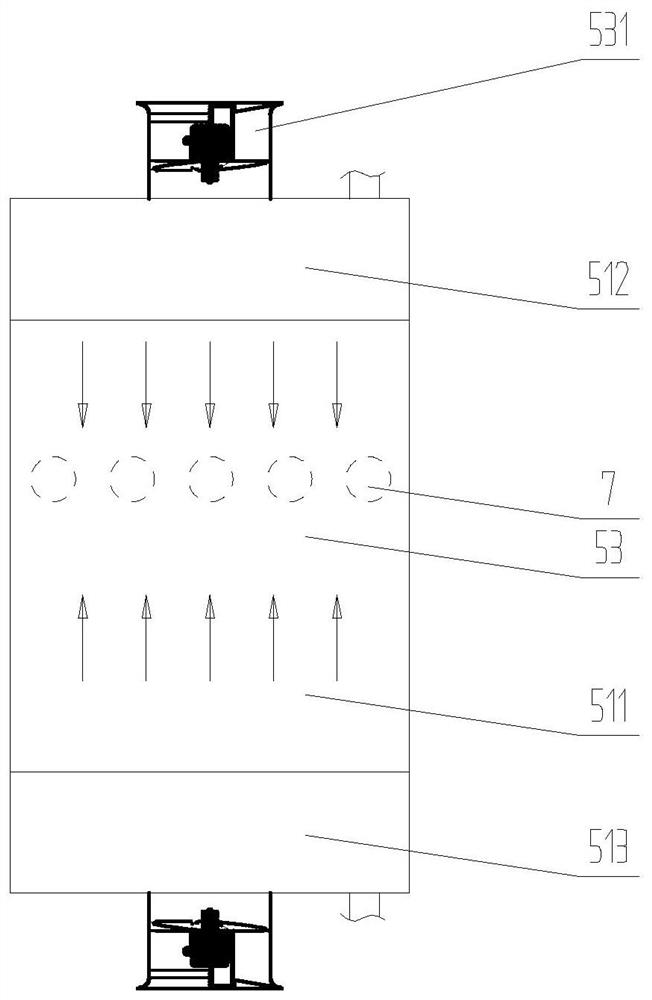

[0019] The present invention is further described below with reference to the accompanying drawings and specific embodiments, and "left", "right", etc. figure 1 For reference directions:

[0020] like Figure 1 ~ 4 As shown, a mixed film is highly efficient cooling system, including water-cooled device 1, air cooling device 5, thermal energy integrated device 6, film conveyance belt 7, water cooling device 1, and the air cooling device 5 sequentially connected to a spacer dip coating The chamber 2, the drying device 3, the transition chamber 4, the film is formed from the opening machine, and it is necessary to pass a series of cooling. After the cutoff can be cut, it can be made of sheet finished product, just from the opening The tape from the machine is generally at a high temperature of around 160-170 ° C. After cooling by the water-cooled device 1, the film can be cooled to 80-90 ° C, effectively alleviate the cooling burden of the subsequent air cooling device 5, and the film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com