Automatic orange peeling machine

A peeling machine and automatic technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of affecting production efficiency, unable to guarantee peeling continuity, affecting taste, etc., to achieve fast peeling speed and reduce labor cost, and the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, not all of them.

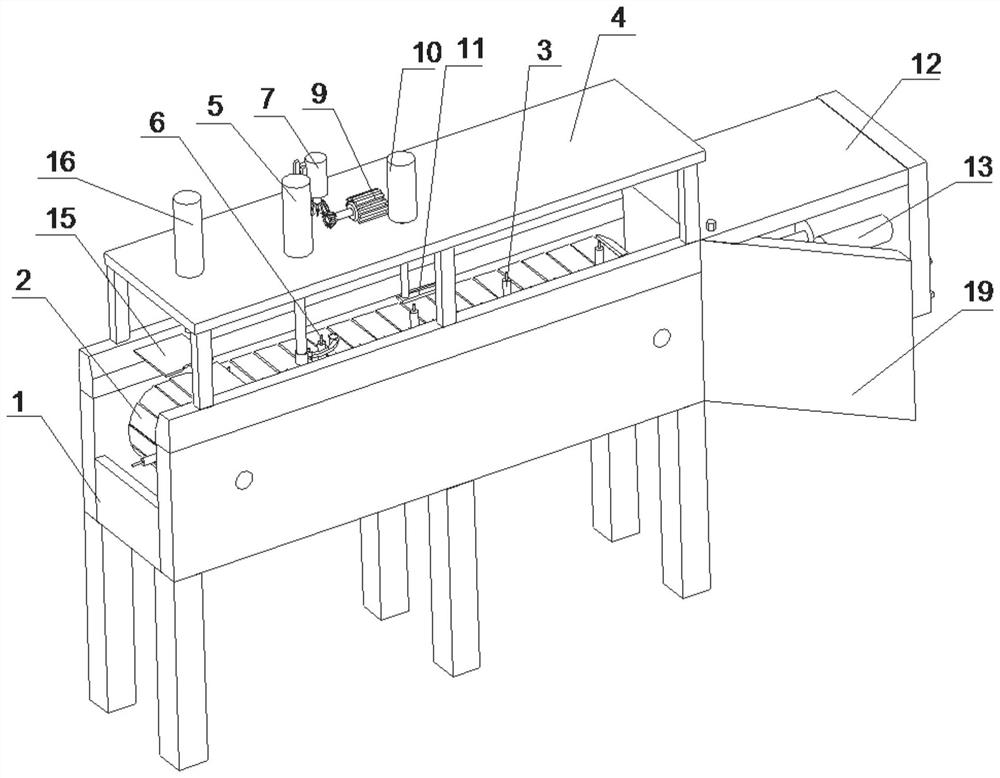

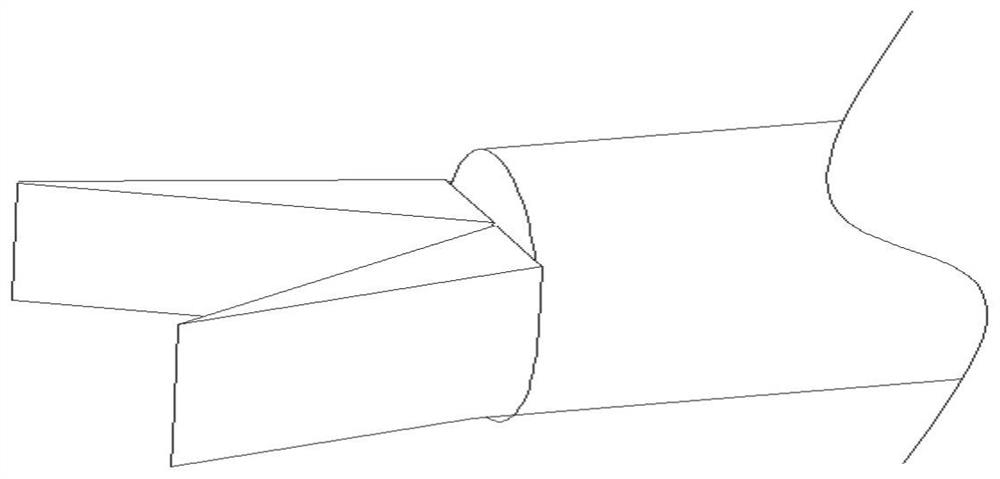

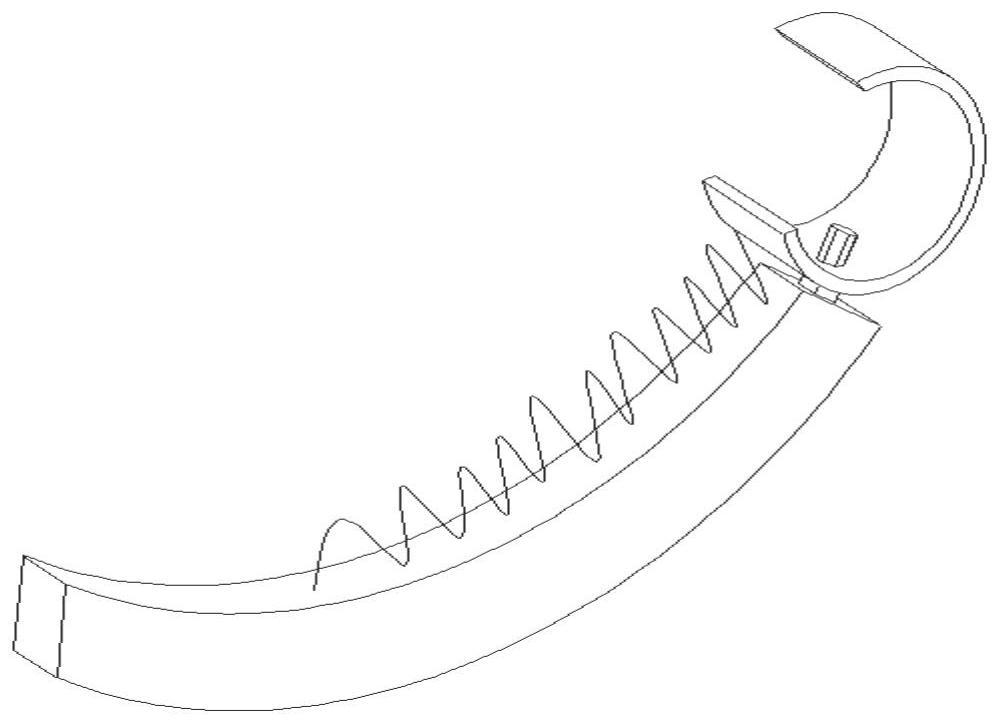

[0017] refer to Figure 1-4 , an automatic orange peeling machine, comprising a frame 1, a transmission mechanism 2 is horizontally arranged on the frame 1, the transmission mechanism 2 is driven by a stepping motor, and a plurality of insertion rods 3 are evenly spaced along the rotation direction on the transmission mechanism 2, The top of the frame 1 is provided with a mounting frame 4, the first automatic telescopic rod 5 on the mounting frame 4, and the first automatic telescopic rod 5 rod body bottom is elastically connected with a peeling knife 6 and it is positioned at one side of an insertion rod 3, and the insertion rod 3 The mounting frame 4 directly above is provided with a second automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com