Naphthalene water reducer sulfonation condensation tail gas recovery process

A naphthalene-based water-reducing agent and tail gas recovery technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of large loss of naphthalene, inability to effectively recover naphthalene vapor, etc., and achieve the effect of increasing water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

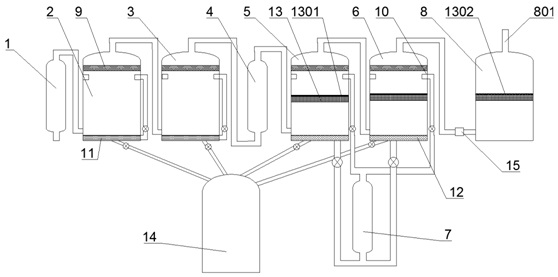

[0033] refer to figure 1 , a naphthalene-based water reducer sulfonation condensation tail gas recovery process is characterized in that it includes a condenser, an lye spray tower, a formaldehyde-removing adsorption spray tower, and an emptying tower 8; a condenser, an lye spray tower 1. The formaldehyde-removing adsorption spray tower and the emptying tower 8 are connected by pipelines, and the gas enters from the bottom of each device and is discharged from the top of the device. The pipeline connecting the emptying tower 8 and the formaldehyde-removing adsorption spray tower is installed with Fan 15, fan 15 attracts the gas of the previous step, and at the same time gives a thrust when the gas is evacuated. The body recovery process includes the following steps:

[0034] a. First, the mixed gas enters the condenser-1 to cool the gas;

[0035] B, the gas after cooling enters lye spray tower one 2 and lye spray tower two 3 successively, and the middle and upper parts of des...

Embodiment 2

[0041] refer to figure 1, a naphthalene-based water reducer sulfonation condensation tail gas recovery process is characterized in that it includes a condenser, an lye spray tower, a formaldehyde-removing adsorption spray tower, and an emptying tower 8; a condenser, an lye spray tower 1. The formaldehyde-removing adsorption spray tower and the emptying tower 8 are connected by pipelines, and the gas enters from the bottom of each device and is discharged from the top of the device. The pipeline connecting the emptying tower 8 and the formaldehyde-removing adsorption spray tower is installed with Fan 15, fan 15 attracts the gas of the previous step, and at the same time gives a thrust when the gas is evacuated. The body recovery process includes the following steps:

[0042] a. First, the mixed gas enters the condenser-1 to cool the gas;

[0043] B, the gas after cooling enters lye spray tower one 2 and lye spray tower two 3 successively, and the middle and upper parts of desc...

Embodiment 3

[0049] refer to figure 1 , a naphthalene-based water reducer sulfonation condensation tail gas recovery process is characterized in that it includes a condenser, an lye spray tower, a formaldehyde-removing adsorption spray tower, and an emptying tower 8; a condenser, an lye spray tower 1. The formaldehyde-removing adsorption spray tower and the emptying tower 8 are connected by pipelines, and the gas enters from the bottom of each device and is discharged from the top of the device. The pipeline connecting the emptying tower 8 and the formaldehyde-removing adsorption spray tower is installed with Fan 15, fan 15 attracts the gas of the previous step, and at the same time gives a thrust when the gas is evacuated. The body recovery process includes the following steps:

[0050] a. First, the mixed gas enters the condenser-1 to cool the gas;

[0051] B, the gas after cooling enters lye spray tower one 2 and lye spray tower two 3 successively, and the middle and upper parts of des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com