Clinical pharmaceutical medicament preparation device

A medicine and pharmacy technology, which is applied in the medical field, can solve the problems that the medicine powder is easy to stick to the inner wall of the device, cannot dissolve solid medicine and liquid medicine, and consumes physical strength of medical staff, so as to save physical strength, avoid waste, and stir thoroughly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

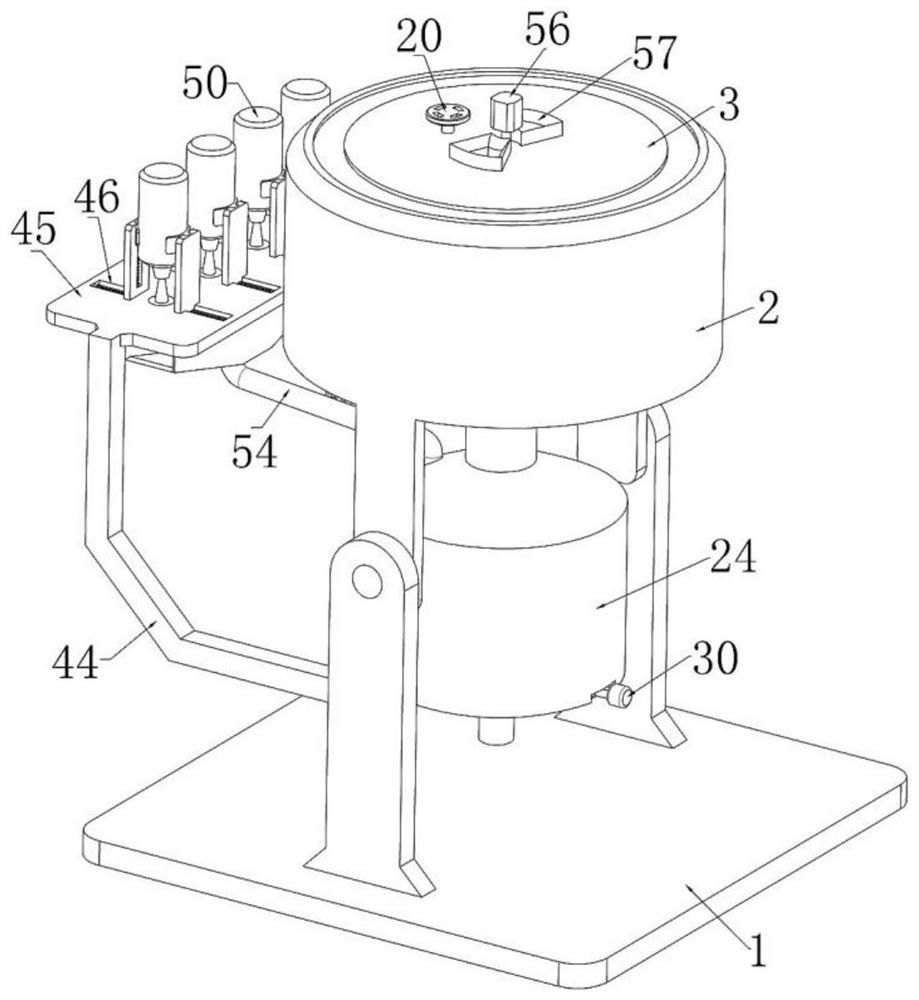

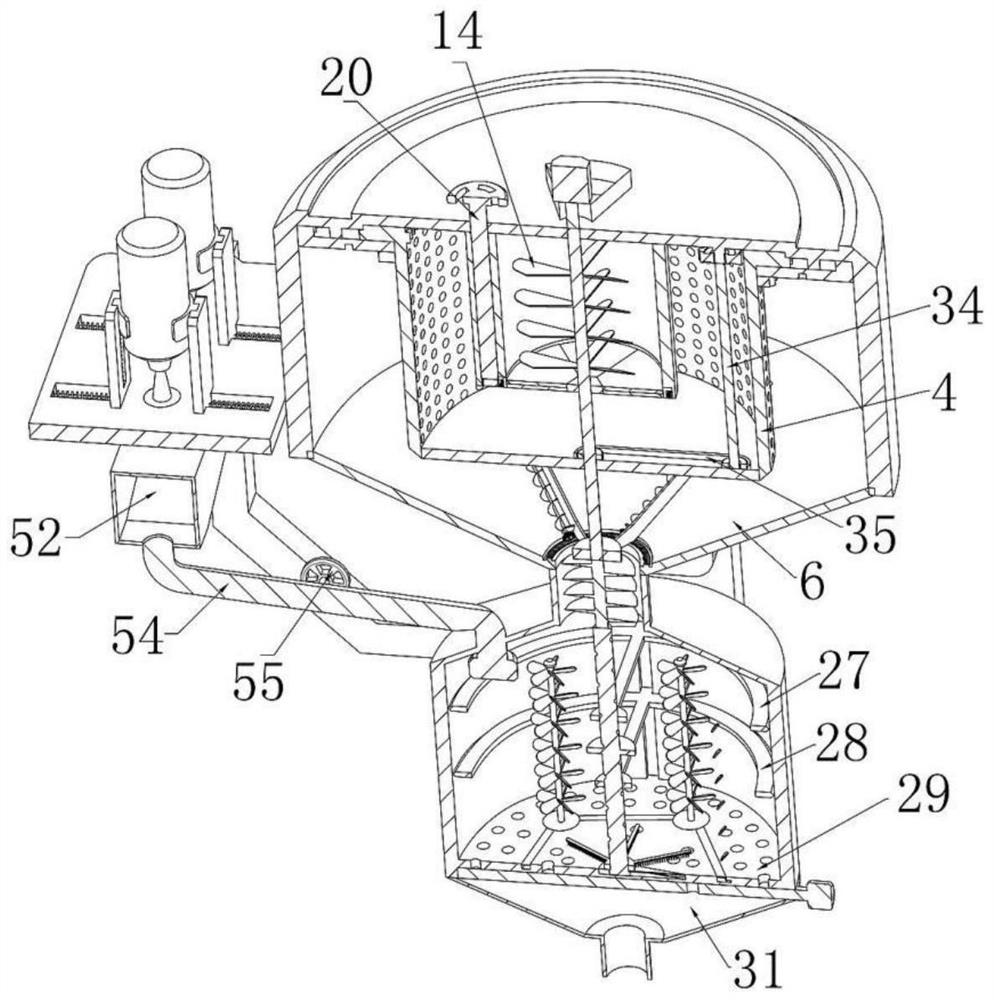

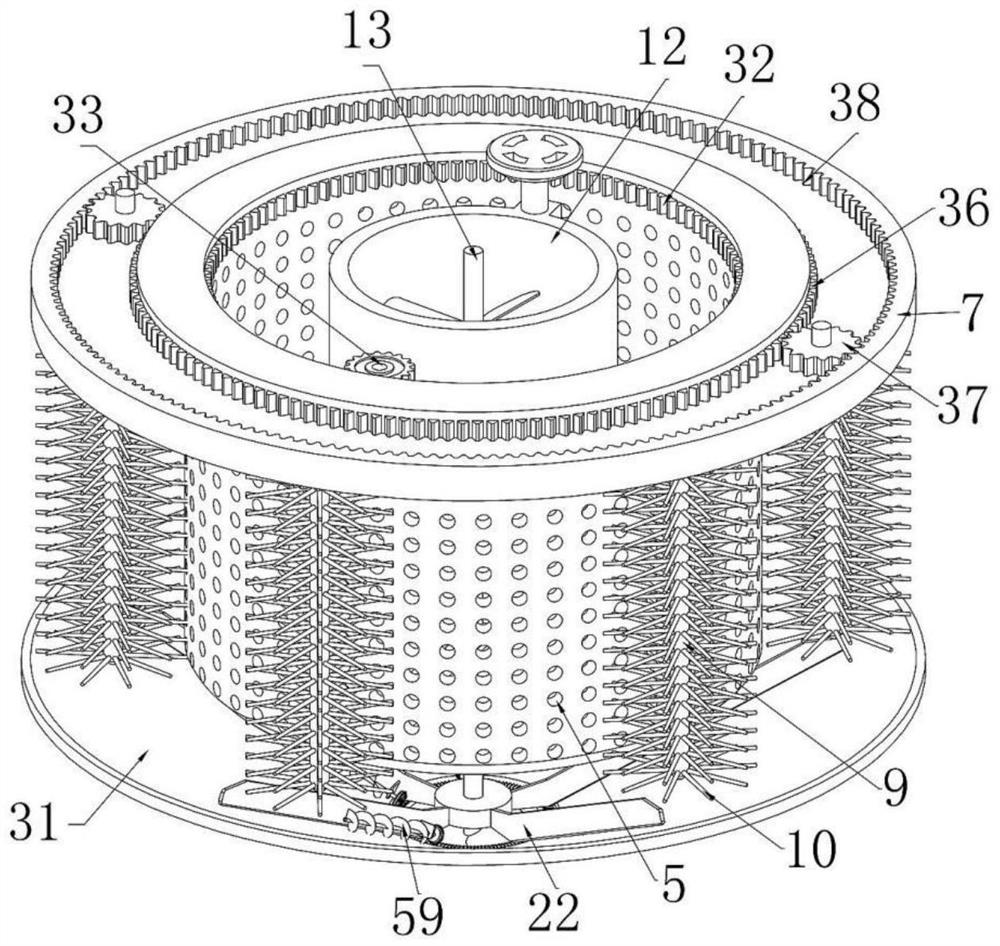

[0042] Example one, as Figure 1-4 As shown in the figure, a clinical pharmaceutical preparation device includes a base 1, the left and right upper ends of the base 1 are respectively fixed with vertical plates, and a separation box 2 with a cavity structure is fixedly connected between the upper ends of the two vertical plates. , the upper end of the separation box 2 is fixedly connected with a cover plate 3, the bottom of the cover plate 3 is rotatably connected with a separation cylinder 4 located in the separation box 2, and the upper end of the separation cylinder 4 and the cover plate 3 pass through. The outlet, a closure cover is detachably connected to the outlet, a plurality of filter holes 5 are evenly opened on the outer wall of the separation cylinder 4, and the bottom of the separation box 2 is fixedly connected with a conical bucket 6 located below the separation cylinder 4 , the bottom of the cover plate 3 is rotatably connected with a swivel 7 located outside t...

Embodiment 2

[0045] Embodiment 2, on the basis of Embodiment 1, as figure 2 , 13 , 14, the crushing device includes a crushing cylinder 12 that is fixedly connected to the bottom of the cover plate 3 and located in the separation cylinder 4, and the cover plate 3 is rotatably connected to the crushing rod 13 located in the crushing cylinder 12, so A plurality of blades 14 are fixedly connected to the crushing rod 13, and a six-sided block 15 that is flush with the bottom of the crushing cylinder 12 is rotatably connected to the crushing rod 13, and a fixing ring 16 is fixedly connected to the bottom of the crushing cylinder 12. , a fan-shaped plate 17 is rotatably connected to each surface of the six-sided block 15, and the circumferential outer end of each of the fan-shaped plates 17 is respectively fixedly connected with a reversing shaft passing through the fixing ring 16, and each reversing shaft Reversing gears 18 are respectively coaxially and fixedly connected to the shaft, and th...

Embodiment 3

[0047] Embodiment 3, on the basis of embodiment 2, as Figure 7-8 As shown, the lower end of the crushing rod 13 is coaxially and fixedly connected with a circular plate 21 located at the outlet of the conical bucket 6. The diameter of the outlet at the lower end of the conical bucket 6 is larger than the diameter of the circular plate 21. The shaped plate 21 is evenly and fixedly connected with a plurality of scrapers 22 that are close to the inner slope of the conical bucket 6, and the crushing rod 13 is fixedly connected with a descending auger 23 located in the outlet of the conical bucket 6;

[0048] When the powdered medicine falls into the conical bucket 6, the crushing rod 13 is rotated at this time, and then the crushing rod 13 rotates with the descending auger 23. At this time, the descending auger 23 accumulates at the outlet of the conical bucket 6 with the descending auger 23. The medicine powder at the location is transported into the corresponding container, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com